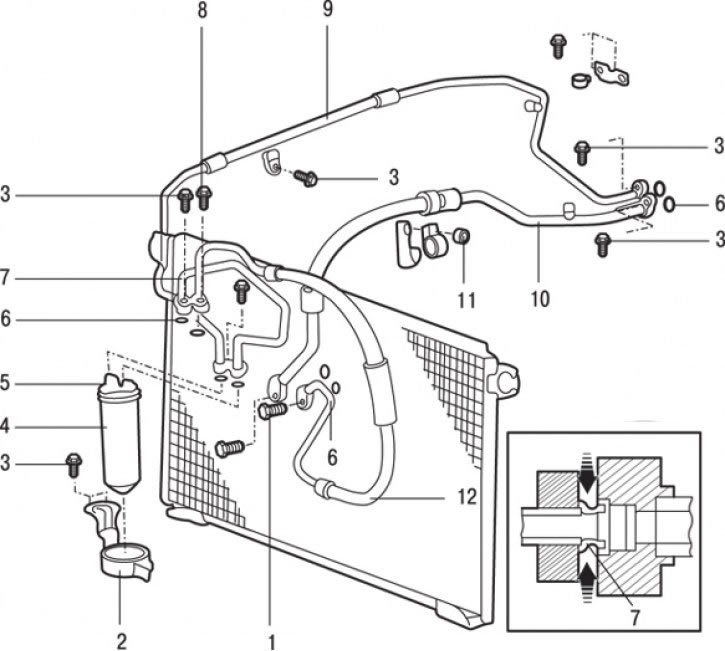

Pic. 18.2. Air conditioning piping: 1 - flange bolt (25 Nm) or bolt with washer (30 Nm); 2 – receiver bracket; 3 - flange bolt (10 Nm) or bolt with washer (6 Nm); 4 - receiver assembly; 5 - double pressure sensor; 6 - annular sealing gasket; 7 - high pressure tube A; 8 - flange bolt (25 Nm) or bolt with washer (15 Nm); 9 - high pressure tube B; 10 - low pressure hose; 11 - flange nut (10 Nm) or nut with washer (6 Nm); 12 - high pressure hose

The location of the pipelines of the air conditioning system is shown in fig. 18.2.

Kinked hoses or sharp bends in the air conditioning pipes greatly reduce the efficiency of the system. During the operation of the air conditioner, high pressures are created in the system, so special attention must be paid to the reliable tightening of all connections. When the air conditioning system is depressurized (when replacing parts and assemblies), foreign matter and moisture may enter.

The following precautions must be observed when servicing and repairing the air conditioning system.

1. Before disconnecting any connection of the air conditioning system (or replace parts), it is necessary to completely pump out the refrigerant from the system. Loosen the air conditioning system connections carefully, even after the system has been drained of refrigerant. If there are signs of high pressure when loosening any fitting, wait and relieve the pressure very slowly.

2. Never attempt to re-bend tubes that have already been bent during assembly. When laying flexible hoses, follow the rule - the bending radius of the hose must be at least 10 hose diameters.

3. Sharper hose kinks reduce refrigerant volume flow. Flexible hoses must not be located closer than 80 mm from the exhaust manifold. Flexible hoses must be checked for condition and proper installation at least once a year. All o-rings of standard air conditioning connections are non-reusable.