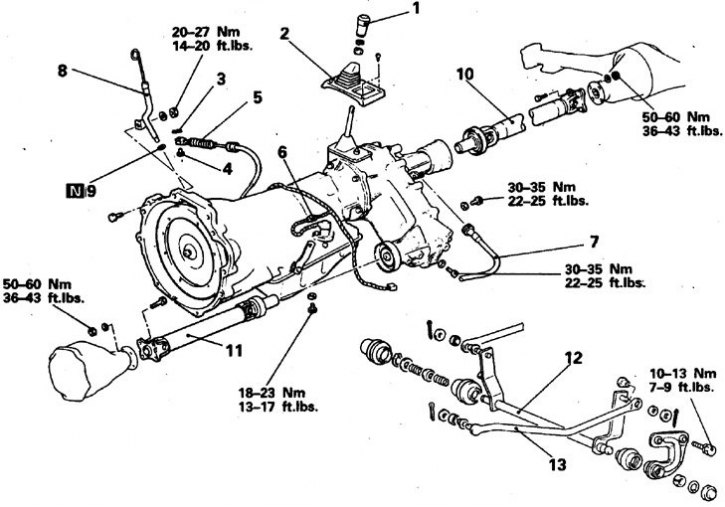

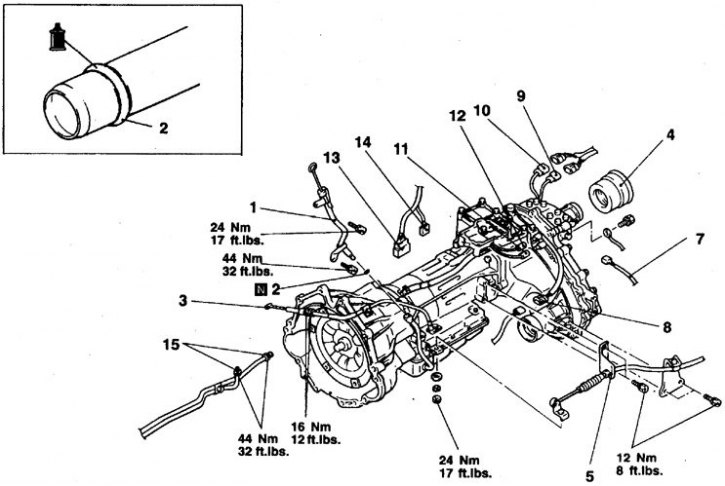

Automatic transmission KM148 (1987-89)

1. Handle; 2. Panel; 3. Cotter pin; 4. Axis; 5. Throttle cable; 6. High gear solenoid valve connector (overdrive valve); 7. Speedometer cable; 8. Branch pipe for filling and checking the liquid level; 9. Ring; 10. Rear driveshaft; 11. Front propeller shaft; 12. Shaft of transverse thrust; 13. Thrust

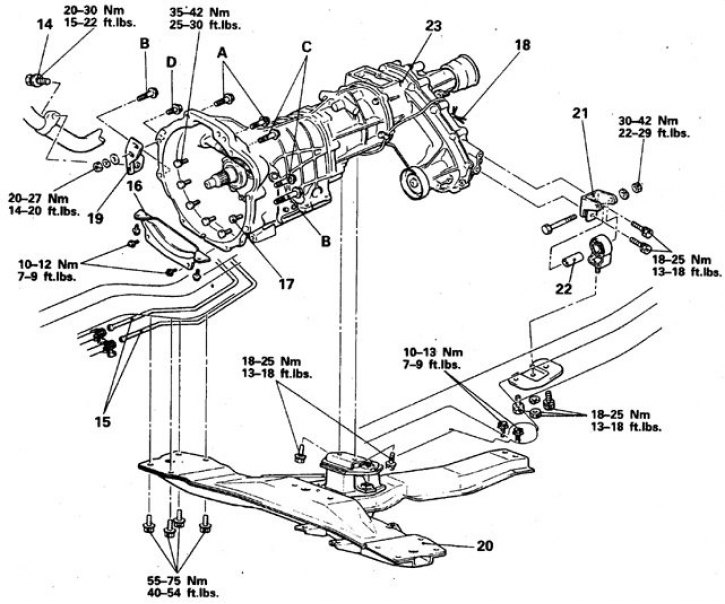

Automatic transmission KM148 (1987-89), continuation

14. Exhaust pipe mounting bolt; 15. Transmission fluid cooler tubes; 16. Torque converter access cover; 17. Special bolts; 18. Connector for the sensor of the control lamp for turning on the front drive axle; 19. Exhaust pipe bracket; 20. Crossbar; 21. Transfer box bracket; 22. Sleeve; 23. Transmission assembly with transfer case

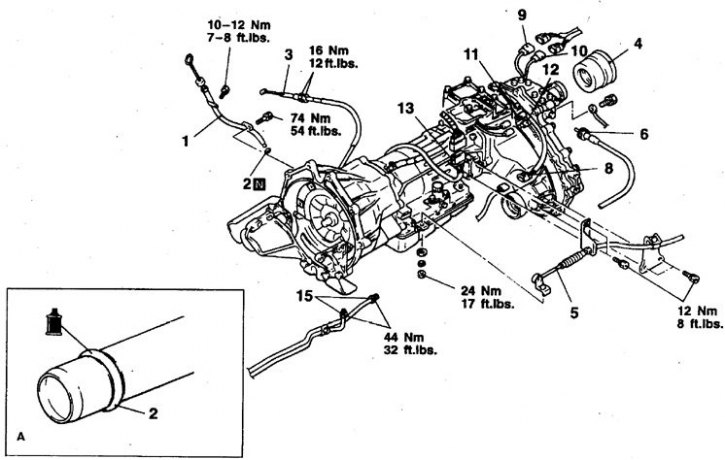

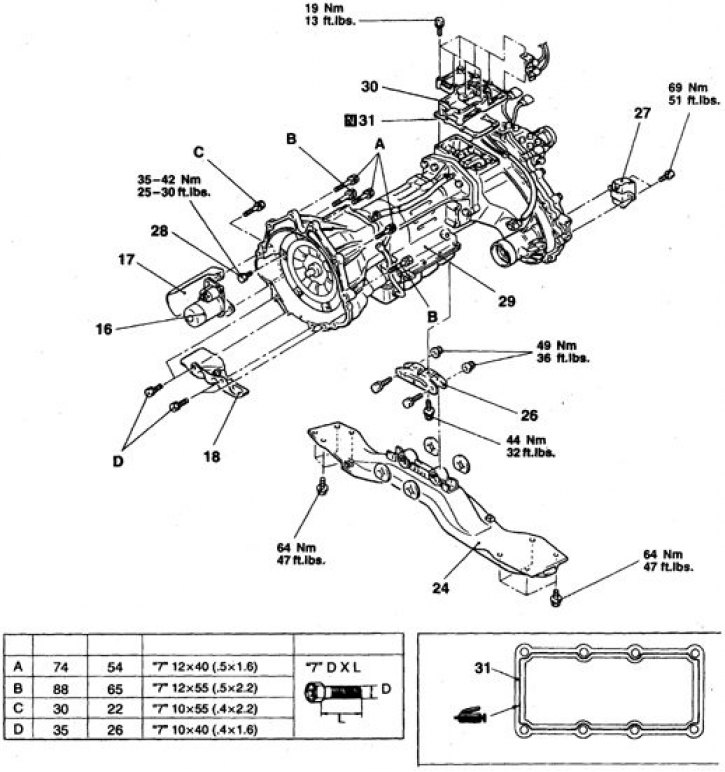

Automatic transmission V4AW2 (1990-98)

1. Pipe for filling and checking the liquid level; 2. Ring; 3. Throttle cable end; 4. Dust cover; 5. Cable control transmission; 6. Speedometer cable; 8. HIGH/LOW position switch connector; 9. Socket of the gauge of a control lamp of inclusion of a drive on all wheels; 10. Sensor connector for center differential operation in lock mode; 11. Sensor connector center differential lock; 12. Front axle enable sensor connector; 13. Blocking switch connector; 15. Cooler tube; A. Lubricate with DIAMOND ATF SP or equivalent; N - to be replaced

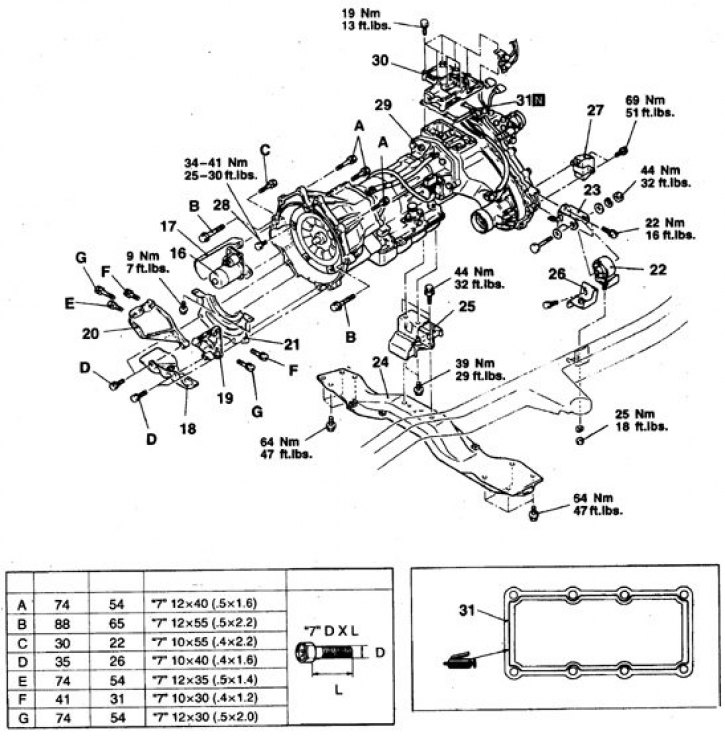

Automatic transmission V4AW2 (1990-98), continuation

16. Starter; 17, 18. Shield; 19, 20. Brackets; 21. Torque converter access cover; 22. Torsion support transmission; 23. Transfer box bracket; 24. Crossbar; 25. Engine support buffer; 26. Transfer box shield bracket; 27. Buffer; 28. Torque converter bolt; 29. Transmission assembly with transfer case; 31. Gasket; A. Bolt designation; B. Tightening torque; B. Bolt dimensions L and D

Automatic transmission V4AW3 (1994-98)

1. Pipe for filling and checking the liquid level; 2. Ring; 3. Throttle cable end; 4. Dust cover; 5. Cable control transmission; 7. Speed sensor connector; 8. Socket switch positions HIGH / LOW transfer case; 9. Socket of the gauge of a control lamp of inclusion of a drive on all wheels; 10. Sensor connector for center differential operation in lock mode; 11. Connector for the sensor-detector of the center differential lock; 12. Connector for the sensor-detector of the front axle; 13. Blocking switch connector; 14. Solenoid valve connector; 15. Cooler tube; A. Lubricate with DIAMOND ATF SP or equivalent; N - to be replaced

Automatic transmission V4AW3 (1994-98), continuation

16. Starter; 17, 18. Starter shield; 24. Crossbar; 26. Bracket rear engine mount; 27. Buffer; 28. Torque converter mounting bolt; 29. Transmission assembly with transfer case; 30. The transmission control mechanism housing; 31. Gasket; A. Bolt designation; B. Tightening torque; B. Bolt dimensions L and D

Cars 1983-89

1. Disconnect the battery from the ground.

2. Remove a forward exhaust pipe, having disconnected from a collector and converter.

3. Disconnect the kick-down link.

4. Remove a cover of the selector and the selector panel, remove the selector.

5. Raise the car, remove the transfer box guard.

6. Remove the mechanism for changing transmission gears and transfer case control.

7. Drain the transmission fluid.

8. Disconnect the cooler pipes, plug and secure in a vertical position.

9. Disconnect cardan shafts.

10. Disconnect wires and cables from transmission.

11. Turn away bolts of fastening of the hydrotransformer for what remove a cover and turn a crankshaft, turning away bolts successively.

12. Remove the starter, move aside and secure (it is recommended to disconnect the wires first).

13. Remove the rear transmission support from the cross member.

14. Remove the crossbar, taking into account the significant weight and dimensions of this part.

15. Remove the transfer box support, unscrew the bolts securing the bell housing and remove the transmission by moving it back, lowering it and removing it from the guide pins.

16. Installation is carried out in the reverse order.

17. Replace all gaskets and seals, tighten the connections to the torques shown in the illustration.

18. Bolts of fastening of the hydrotransformer to a flywheel tighten with the moment of 35–42 Нм.

19. Adjust rods and cables.

Cars 1990-98

1. Disconnect the battery from the ground.

2. Remove the transfer case control mechanism.

3. Raise the car, remove the transfer box guard.

4. Remove a forward exhaust pipe, having disconnected from a collector and converter.

5. Drain transmission fluid and transfer case oil.

6. Disconnect cardan shafts, marking their position.

7. Feed forward a forward shaft, incline and get from a reducer.

8. Remove the filling pipe.

9. Disconnect the thrust from the transmission, remove the cover from the crankcase shank.

10. Designate and disconnect from transmission of wires and cables, including a speedometer cable.

11. Disconnect the cooler tubes from the transmission.

12. Remove starter and heat shield (if provided).

13. Place a jack under the engine tray.

14. Place a trolley with a jack under the transmission, but do not hang the transmission yet.

15. Slightly hang out the engine and remove the right and left forward support.

16. Remove the bottom cover of the bell housing.

17. Remove the transfer case bracket, torsion bar, buffer and shield bracket.

18. Slightly hang out the transmission.

19. Turn away 2 bolts of a cross-beam, raise a jack on 6 mm and remove a cross-beam.

20. Remove transmission. When removing, do the following.

21. Remove the cover

22. Turn away 6 bolts of fastening of the hydrotransformer, having asked the assistant to turn a crankshaft.

23. Carefully lower the rear of the transmission assembly with transfer case and remove from the engine.

24. Tilt the front of the transmission and lower it carefully, being careful not to touch the rear extreme cross member, and remove from under the car.

25. Installation is carried out in the reverse order.

26. Replace all gaskets and seals, tighten the connections with the moments indicated in the illustration

27. Tighten the torque converter mounting bolts to the flywheel with a torque of 34–41 Nm, the transmission mounting bolts with a torque of 75 Nm, the cross member bolts with 6 Nm.

28. Adjust the transmission control actuators.