Attention! To dismantle engines of all modifications, it is necessary to remove the transmission, transfer case and front propeller shaft (see subsection 9.3.6, subsection 9.1.6 and subsection 9.3.9). When dismantling the engine, apply marks of mutual orientation to the removed units and the hood, clearly mark all detachable wires and hoses. When removing engines with a volume of 3.0 liters and 3.5 liters, do not allow the temporarily disconnected air conditioner and power steering pump to sag on the hoses. Please note that when removing the engine, you should be extremely careful, since the gaps between the engine and body panels are small, and the unit itself has a significant weight.

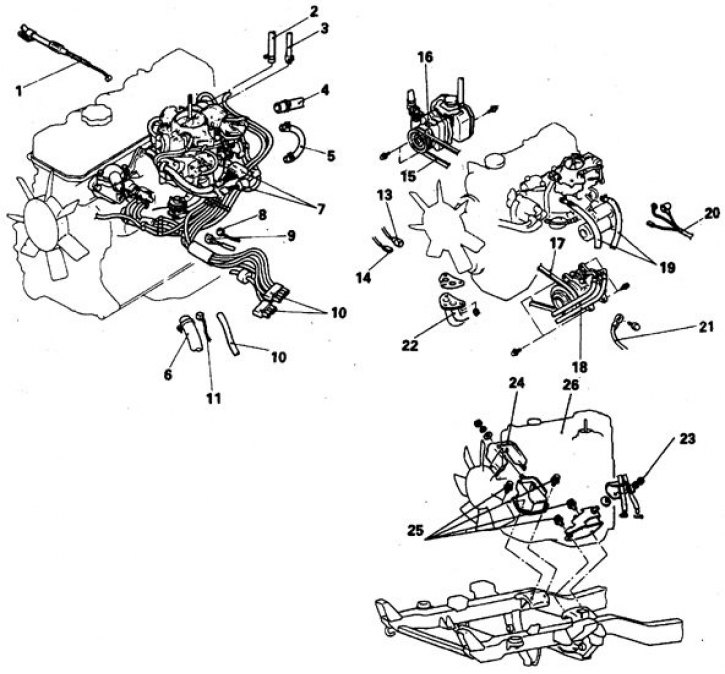

Detachable hoses and wires when dismantling a 4-cylinder engine

1. Throttle cable; 2. Heater hose; 3. Brake booster hose; 4. Bypass hose of the cooling system; 5. Coolant hose; 6. Radiator hose; 7. Engine control harness; 8. A/C fluid temperature sensor connector; 9. Connector for the sensor of the liquid temperature indicator for the air conditioner; 10. Vacuum hose; 11. Socket of the gauge of temperature of a liquid of a control system of the engine; 13. Oxygen sensor connector; 14. Connector oil pressure sensor; 15. Power steering pump belt; 16. Power steering pump; 17. A/C compressor belt; 18. Air conditioning compressor; 19. Petrol pipeline; 20. Generator connector; 21. Wire to ground; 22. Front exhaust pipe; 23. Bracket for fastening the gas pipeline; 24. Shield; 25. front support bolt; 26. Engine

Removing

1. Depressurize the air conditioner (if provided) in a car service.

2. Remove the hood.

3. Raise the vehicle and remove the engine guards.

4. Drain the liquid from the cooling system.

5. Drain the oil from the transmission, engine, transfer case and front reduction gear.

6. Remove the air filter.

7. Remove both fan shrouds.

8. Remove the radiator.

9. Disconnect the throttle cable.

10. Disconnect the engine heater, cooling system and brake booster hoses.

11. Disconnect the large multi-pin connector of the engine management wiring.

12. Disconnect a vacuum hose and turn out the gauge of the index of liquid temperature.

13. Disconnect the wires from the oxygen sensor and from the oil pressure sensor.

14. Remove the power steering pump belt by releasing the pump mounting bolts.

15. Remove the power steering pump and set aside without disconnecting from the line.

16. Remove the belt and air conditioning compressor. Take the unit to the side without disconnecting it from the line, and secure it.

17. Disconnect fuel hoses after decompressing (on injection engines).

18. Disconnect 3 sockets on the generator.

19. Disconnect a mass wire from the block of cylinders.

20. Disconnect the exhaust pipe from the manifold and secure the pipe with a wire.

21. Disconnect all absorber tank hoses that lead to the bulkhead of the engine compartment.

22. Remove the bracket for fastening the fuel lines on the engine.

23. Attach the hoist hoist and hang the engine.

24. Remove the shield from the right support.

25. Turn away bolts of fastening of support of the engine to a frame.

26. Carefully lift the engine and remove it from the engine compartment. Place the engine on stands (not on pallet).

Installation

Engine installation is carried out in reverse order. First of all, install the engine, wrap the support bolts and tighten them with a torque of 35 Nm. Replace the exhaust manifold gasket and mounting bolts. Tighten the radiator mounting bolts with a torque of 7 Nm. Fill with liquid, oil and start the engine. After warming up, restore fluid levels. Refuel the air conditioner at a car service. Adjust the cable, belts, idle and ignition.