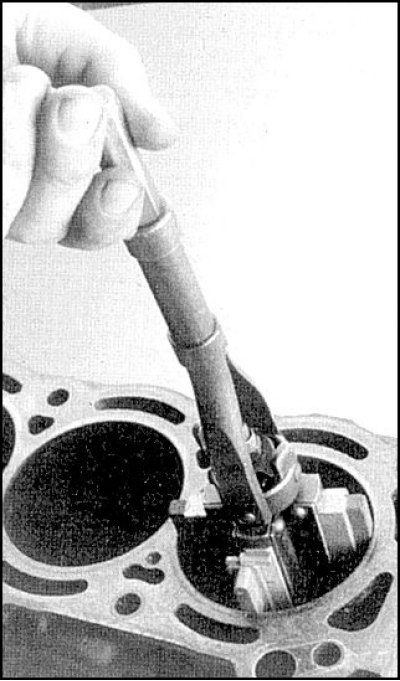

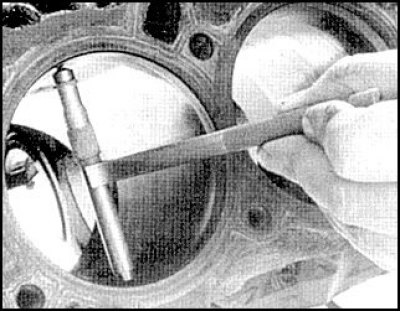

Removing the bead on the top of the cylinder

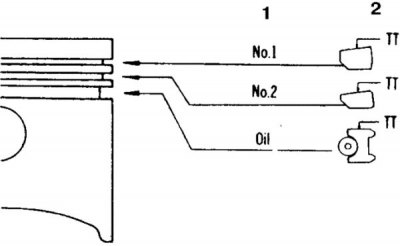

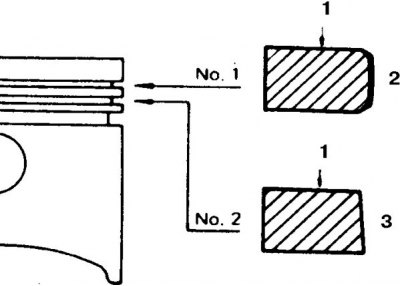

The order of installation of rings on a diesel

1. Installation procedure

2. Marking

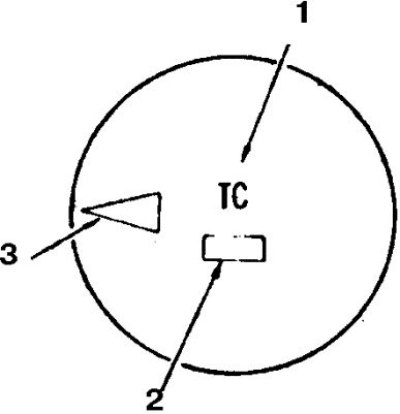

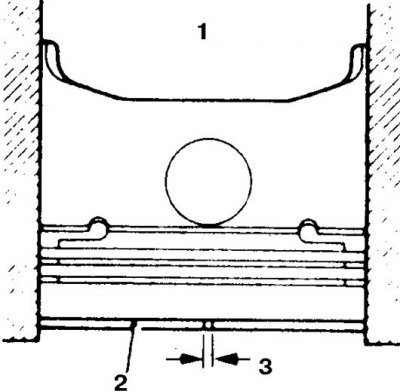

Diesel piston orientation

1. Marking; 2. Stamp of the size group; 3. Arrow (directed forward)

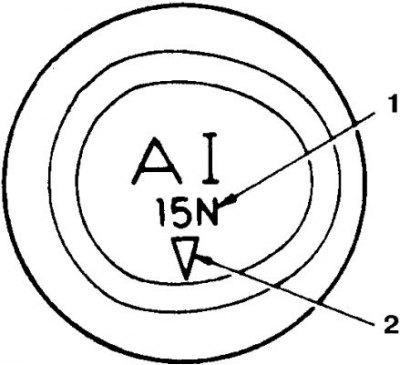

Piston orientation on V6 engines

1. Marking

2. Arrow (directed forward)

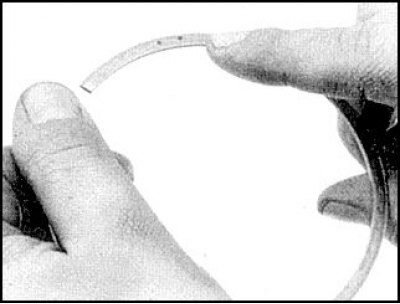

Removing

1. The piston with the connecting rod is pushed out through the top of the cylinder block after the connecting rod cap bolts are loosened and the flange at the top of the cylinder is removed. The connecting rods are marked by cylinder number. Connecting rod caps must be numbered before removal. Remove the rings with a special tool.

2. Clean the pistons by removing carbon deposits.

Examination

1. Check the ovality and taper of the cylinders. To do this, check the diameter of the cylinders by measuring it in the longitudinal and transverse directions relative to the engine axis, in three places - directly under the shoulder, at the bottom of the cylinder and in the middle.

2. If the taper and ovality are within the normal range, then honing the cylinders. Otherwise, the cylinders should be bored and the pistons and rings replaced with repair ones (these procedures are performed in a car service).

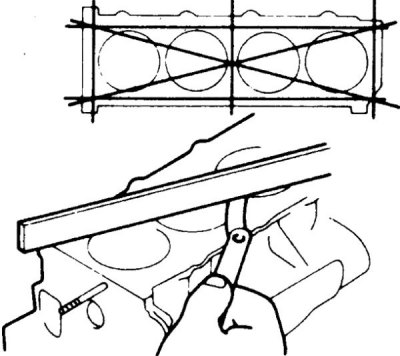

3. Check up deformation of a demountable plane of the block of cylinders. If the deviation from the plane is more than 0.1 mm, then grind the block.

4. Check up a condition of the piston. The presence of cracks near the skirt, as well as deep noticeable scratches and scratches on the side surface is not allowed.

5. Measure the piston diameter in a direction perpendicular to the axis of the piston pin at skirt level. Determine the clearance between piston and cylinder. If the clearance is higher than normal, replace the piston. If, when replacing the piston, the clearance does not correspond to the norm, then bore the cylinders and replace the pistons with repair ones.

6. Check up a backlash between compression rings and a flute in the piston. If the gap is slightly higher than normal, then the rings should be replaced.

7. Check the gaps in the joints of the piston rings by pushing the ring with the piston (1 - piston, 2 - ring, 3 - gap). 15 mm from the bottom edge of the cylinder, the clearances must be correct.

8. Check up a condition of rods external survey. The presence of deformations, curvature of the arc bed under the liner in the lower part and non-parallelism of the connecting rod cover fastening studs are not allowed. There should be no appreciable play of the piston pin in the connecting rod (the pin is pressed into the connecting rod). A damaged connecting rod is straightened in a car service or changed.

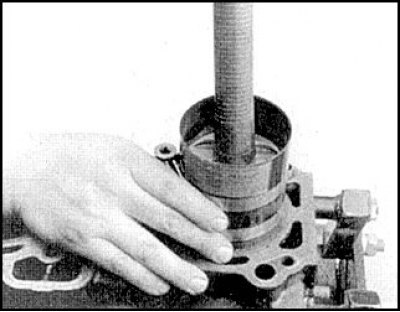

Installation

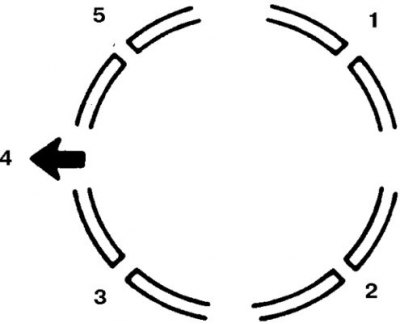

Arrangement of joints of piston rings

1. Top compression; 2. The upper disk of the oil scraper ring; 3. Lower compression and oil scraper ring expander; 4. To the front of the engine; 5. Lower oil ring disc

1. New rings must match the size group of the piston. All gaps in the rings must be checked and correspond to the norm.

2. Install the rings in order: oil wiper, lower compression, upper compression (this ring is installed only with an expander). The mark on the ring should be facing up.

3. The sections of the upper and lower compression rings are different (1 - marking N and T, 2 - rounded profile, 3 - conical profile).

4. Arrange the joints of the piston rings.

5. Lubricate the cylinder, crimp the rings with a tool, correctly orient and insert the piston assembly with rings and connecting rod and upper bearing into the cylinder. Install the lower insert into the cover, secure the cover with nuts. Repeat the procedure for the remaining connecting rods, turning the crankshaft. Tighten the nuts to the specified torque in 2-3 steps.

6. Install all removed parts (if the repair was carried out without removing the engine).