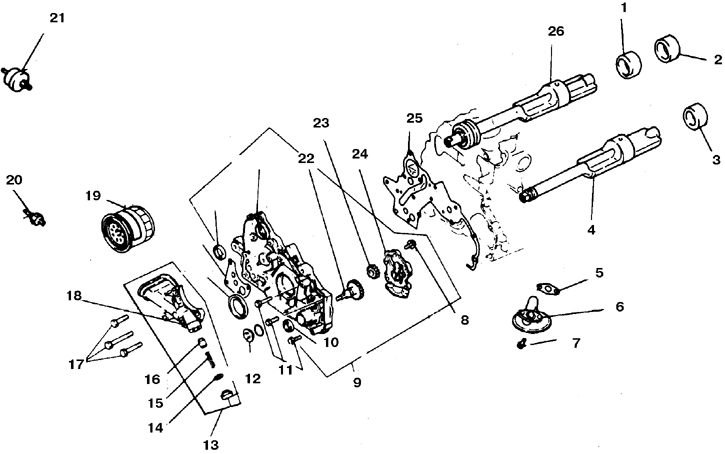

Oil pump and vibration damper rollers (2.0 and 2.4 L)

1. Front bearing; 2. Rear bearing right; 3. Rear bearing left; 4. Left roller; 5, 14, 25. Gasket; 6. Mesh filter; 7, 8, 11, 17. Bolts; 9. Front casing assembly; 10. Oil seal; 12. Plug; 13, 18. Oil filter bracket; 15. Spring; 16. Pressure reducing valve; 19. Oil filter; 20. Emergency oil pressure sensor (Tredia); 21. Oil pressure indicator sensor (Corona); 22. Oil pump drive gear; 23. Driven gear; 24. Lid; 26. Right roller

Attention! Rollers - vibration dampers on V6 engines are absent.

2.0 and 2.4L engines

Removing

1. Disconnect the battery from the ground.

2. Remove timing belts (see subsection 3.4.29).

3. Drain the oil and remove the oil filter.

4. Remove the pan and oil receiver.

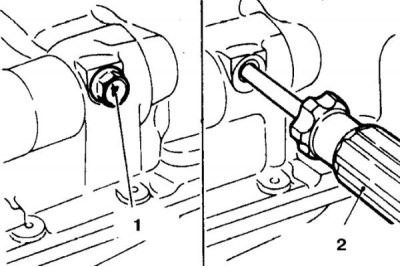

5. Remove the plug and fix the left roller by inserting a screwdriver with a diameter of 8 mm and a length of at least 60 mm.

6. Loosen the right roller bolt and remove the tensioner B. If necessary, remove the roller belt sprocket.

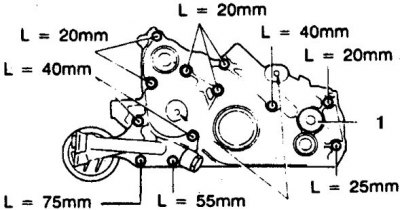

7. Turn away bolts, having paid attention to their arrangement, and remove a forward casing and a lining.

8. Remove the screwdriver and take out the rollers.

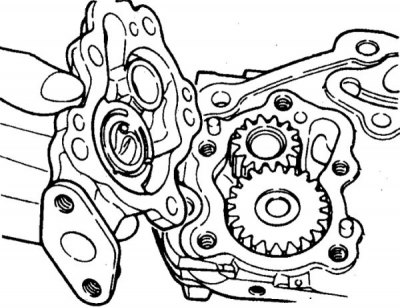

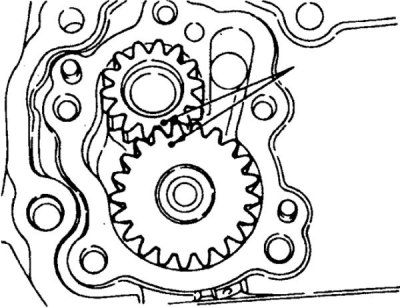

9. Remove the oil pump cover and remove the gears.

10. Check the condition of the pump gears and planes, replace worn parts.

Clean the oil channels. Carefully check the condition of the gland seals in the front cover, replace if necessary. Check for wear and traces of sticking on the rollers.

Installation

1. Check the pressure reducing valve plunger for wear. Install in the front cover, aligning the marks.

2. Lubricate and reinstall the pump gears, matching the marks.

3. Install the pump cover and tighten the bolts to 21 Nm.

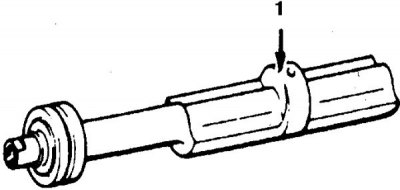

4. Install the rollers carefully without damaging the bearings (1 - plug; 2 - screwdriver).

5. Put drift MD 998285-01 on the crankshaft.

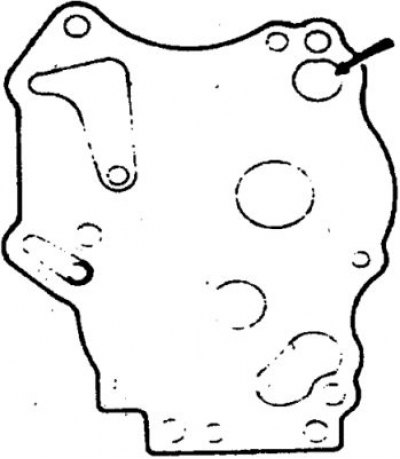

6. Install a new gasket, install the front cover and tighten the bolts.

7. Fix the left roller with a screwdriver, tighten the bolt with a torque of 35 Nm.

8. Install the filter bracket, tighten the cover and bracket bolts to 23 Nm 9 (1 - cap).

9. Put the cap on the left shaft.

10. Assemble the pressure reducing valve, tighten the plug to 45 Nm.

11. Install the oil receiver, pan and oil filter.

12. Install sprockets, toothed belts and adjust their tension (see subsection 3.4.29).

2.6L engine

Removing

1. Remove both chains and sprockets (see subsection 3.4.30).

2. Drain the oil and remove the filter.

3. Disconnect the bypass valve and oil cooler hoses on the bracket.

4. Turn away a bolt and a nut and remove an arm and sealing rings.

5. Remove the pan and oil receiver, remove the gaskets.

6. Remove the parts of the pressure reducing valve, unscrew the bolts and remove the oil pump housing.

7. Remove the pump gears, remove the key from the vibration damper shaft.

8. Remove the pump cover with gasket.

9. If necessary, remove the left roller. To do this, screw 2 M8 bolts into the threaded holes of the flange and, turning the bolts, press out the stop. Remove the right roller if necessary.

Installation

1. Check the condition of the split planes of the pump cover and in the front cover of the engine. Check gear end clearance. If the gap exceeds 0.15 mm, then replace the gears and (or) frame. Clean the oil channels. Check for wear on the rollers.

2. Replace all gaskets and seals.

3. Lubricate the roller journals before installation (1 - lubrication point).

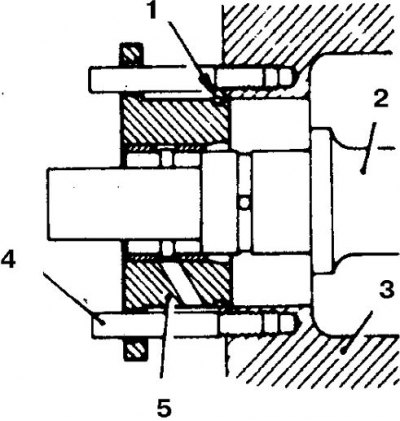

4. Install the roller stop along the M6 guide pins 50 mm long, then remove the pins and tighten the stop bolts with a torque of 11 Nm. (1– ring; 2 - left roller; 3 - block of cylinders; 4 - hairpin M6; 5 - emphasis).

5. When assembling the pump, align the gear marks and fill with about 10 cc. see oils.

6. Tighten the pump cover bolts with a torque of 11 Nm, large pump housing bolts - 65 Nm, small bolts and screws -10 Nm.. pressure reducing valve plug - 10 Nm.

3.0 and 3.5L engines

Removing

1. Disconnect the battery from the ground.

2. Remove the oil gauge.

3. Raise the front of the car.

4. Remove the toothed belt (see subsection 3.4.29).

5. Drain the oil, remove the pan and oil receiver.

6. Turn away bolts and remove the oil pump, having paid attention to an arrangement of bolts.

Installation

1. Install in reverse order

2. Replace gaskets and crankshaft oil seal.

3. Before assembly, fill the pump with petroleum jelly, or fill with oil. Tighten the pump bolts to 15 Nm.