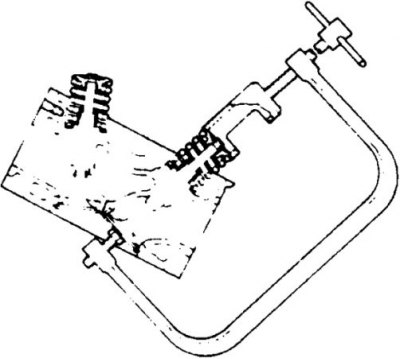

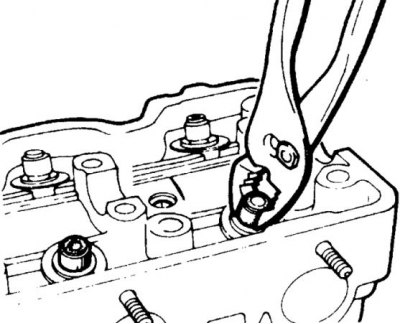

Spring compression during valve installation

Additional valve on Mitsubishi engines

On early Mitsubishi engines, an additional valve is provided that closes the jet screwed into the combustion chamber and is designed to form a jet of combustible mixture directed to the candle in order to improve fuel combustion.

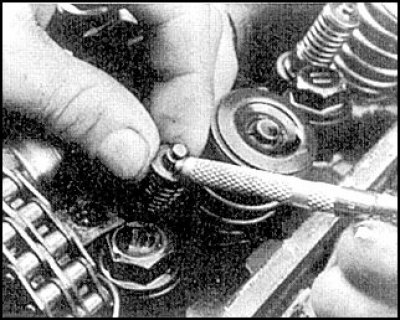

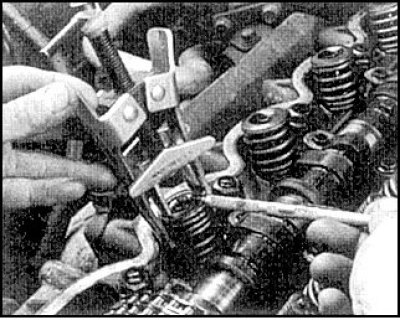

When dismantling the cylinder head, these valves must be removed first. For this, tool MD 998310 is used.

When turning out the jet valve, the device must not be tilted, as the rods of the additional valves may be bent.

Removing

1. When disassembling, compress the first valve spring with a suitable tool and remove the cotters.

2. Release the valve spring, remove the spring plate, spring and support washer.

3. Get the valve and remove an oil scraper cap. Remove carbon deposits from valves.

Examination

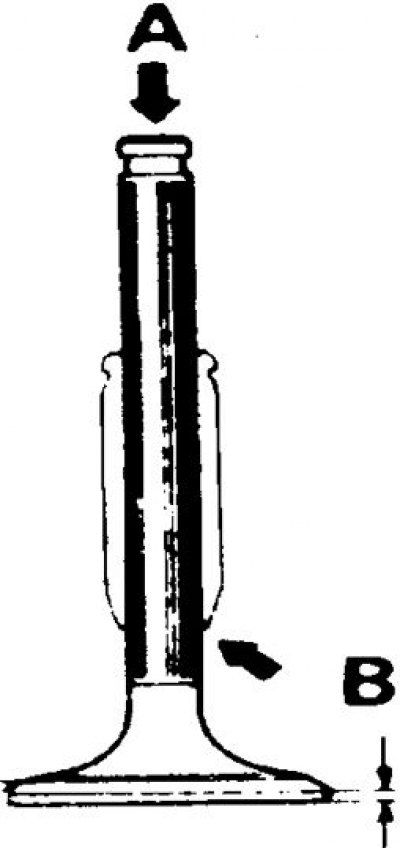

Valve Wear Check Points

A - places to check valve wear at the end

B - places for checking the width of the belt

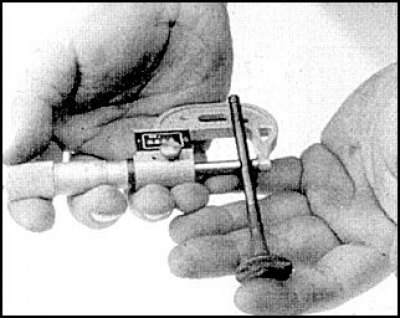

Checking the valve stem diameter

Checking the bending of the rod by rolling

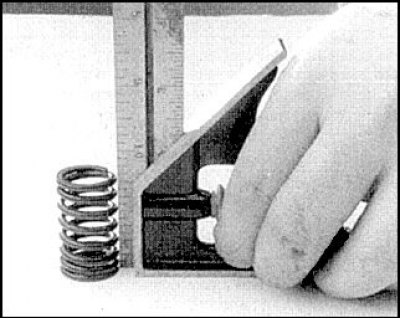

Checking the verticality of the spring

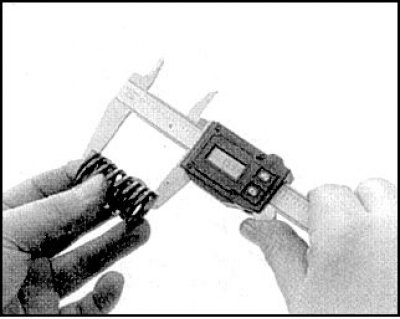

Checking the length of the spring

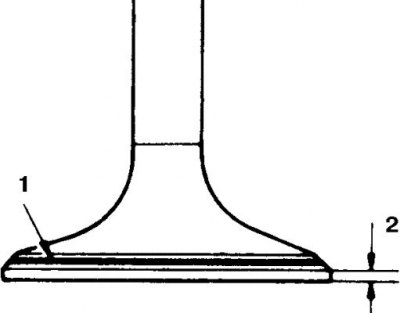

Valve Head Band Width and Seat Band

1. Valve head band

2. Landing belt

Carefully inspect the valves, check for cracks on the chamfers of the valves, traces of uneven wear, metal carryover and burnout. If a wear is found near the entrance to the guide sleeve, ovality of the ends and a decrease in the width of the belt against the norms, replace the valve.

Check the length of the springs and the verticality of the springs (deviation from the vertical is allowed no more than 2°). Replace shrink springs.

Check the clearance of the valves in the sleeves either by the difference between the diameters of the rod and the sleeve, or by shaking the valve in the sleeve. If the gap exceeds the norm, then the valve (or sleeve) replace.

Determine the position and width of the seat band by lubricating the seat with metal-based paint and installing the appropriate valve. If the belt is solid, then the valve and seat can be used further. If the trace is intermittent, then it is necessary to grind the valve and seat and grind the valve to the seat.

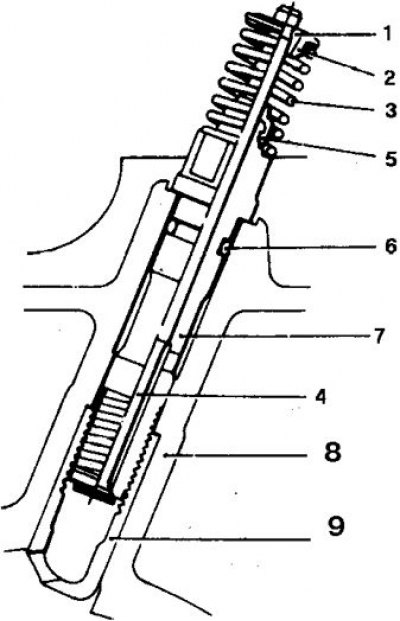

Additional jet valve

1. Washer; 2. Plate; 3. Spring; 4. Jet; 5. Oil seal; 6. Ring; 7. Housing; 8. Cylinder head; 9. Jet nozzles

Valve disassembly

To disassemble the valve, compress the spring, unscrew the nut and remove the crackers. The worn auxiliary valve is replaced as an assembly. The valve can be disassembled to determine its condition (need a fixture). If the parts are in satisfactory condition, then replace only the valve stem seal.

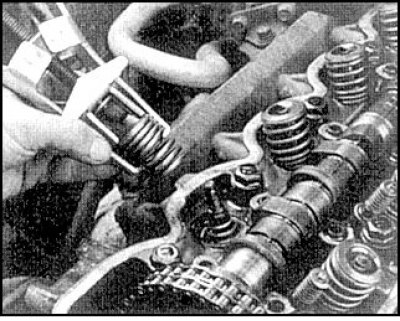

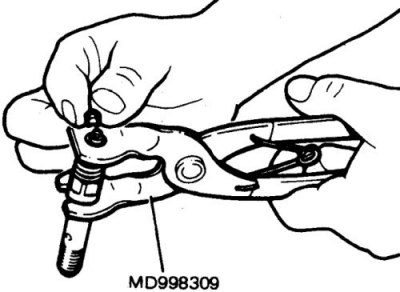

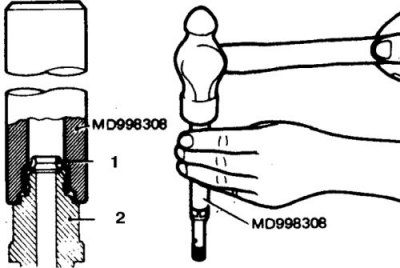

Replacing the oil scraper cap of the additional valve

1. Cap

2. Housing

After disassembly, check the wear of the valve stem, if there are signs of burning and heavy wear (determined by rolling) replace valve assembly. Assemble the valve in reverse order.

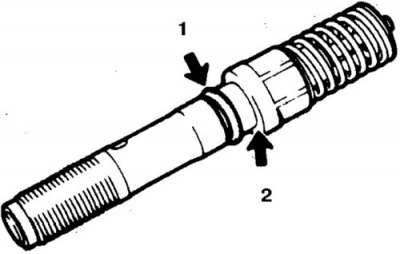

Additional jet valve before installation

1. New ring

2. Lubricate

When installing, tighten the valve with a torque of 18–20 Nm.

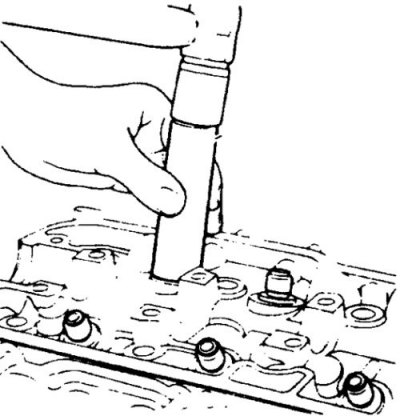

Valve train assembly

Cap pressing

Assembly is carried out in the reverse order. Carefully remove residual lapping material and rinse. Lubricate the rods and press on new caps. Install all removed parts in their original places.