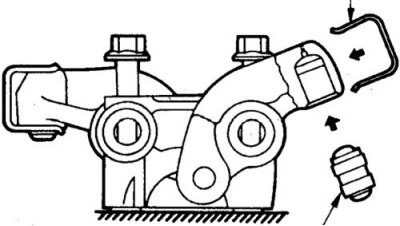

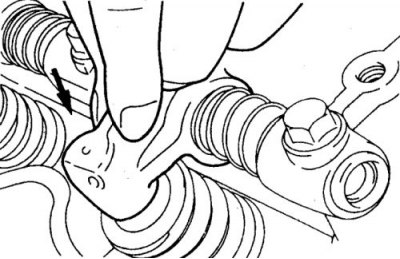

Fixing the hydraulic pusher with a bracket during installation

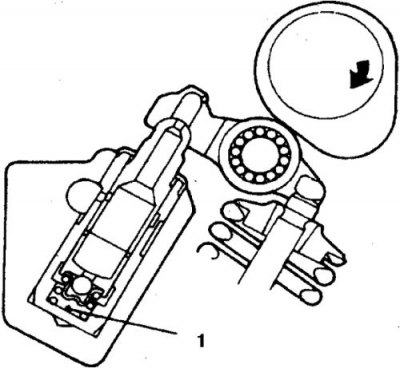

Hydraulic pusher device

1. High pressure chamber

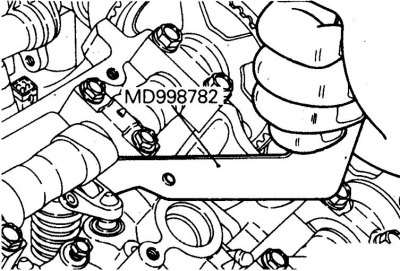

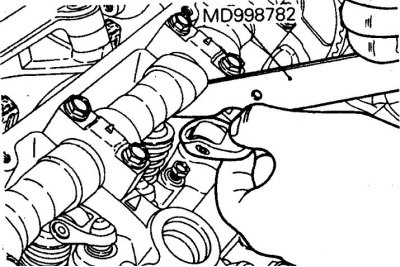

3.5L engines

Removing

1. Depress the valve spring.

2. Remove rocker.

3. Get hydropusher.

4. Replace pusher and install parts in reverse order.

Check without removal from the car

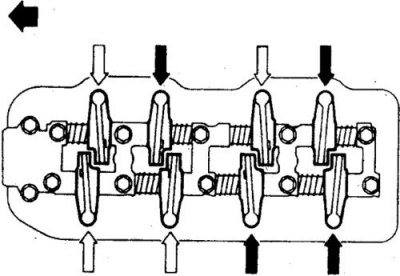

Checked tappets at TDC on 4-cylinder engines and diesel

Light arrows - pushers of the 1st cylinder.

Dark arrows - pushers of the 4th cylinder.

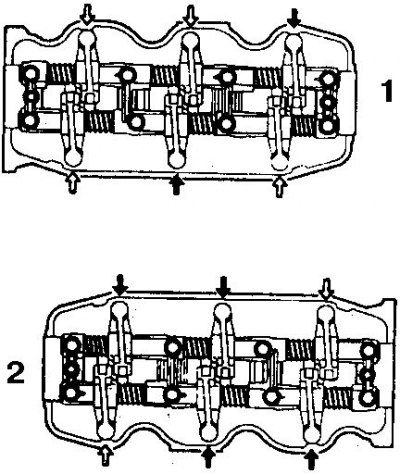

Checking tappets on a 12-valve 3.0L engine

1. Right head

2. Left head

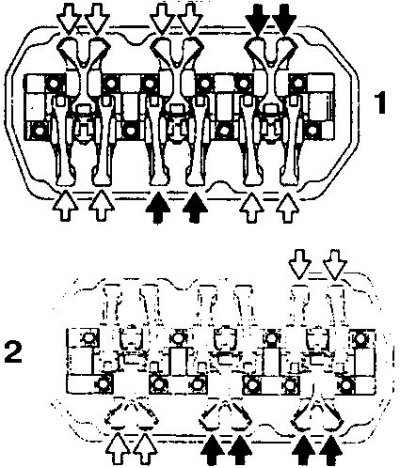

Checking tappets on a 24-valve 3.0L engine

1. Right head

2. Left head

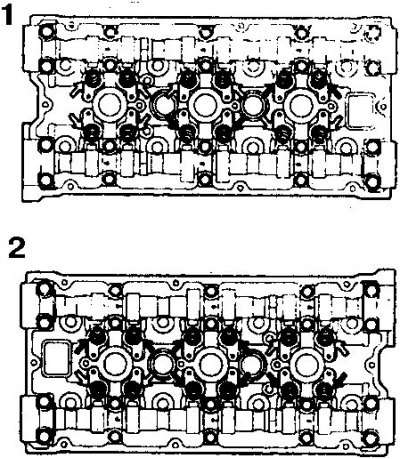

Checking tappets on a 3.5 liter engine

1. Right head

2. Left head

Checking the swing of the rocker on the hydraulic pusher (except for 3.5 l engines)

If there is a loud knocking of the pushers after starting the engine, or if there are steady knocks accompanying the operation of the engine, do the following.

1. Check the oil level and condition, change the oil if necessary. This is due to the fact that knocking may be due to air that has entered the channels of the pushers due to a strong violation of the oil level, or its foaming.

2. Air can be bled from the tappets by repeated slow (within 30 sec) increase in speed up to 3000 rpm (knocks should gradually disappear).

Avoid long periods of car parking with the engine off, or parking on slopes.

3. If it is not possible to remove air in the indicated way, then do the following (on all engines):

- set the piston of the 1st cylinder to the TDC of the compression stroke;

- press the rocker arms indicated by the light arrow, selecting the play between the end of the valve;

- turn the crankshaft 360°and press the rocker arms indicated by the dark arrow, selecting the play between the end of the valve;

- press the rocker arms in place directly above the pushrod. If backlash is felt in a pusher, replace a pusher, having removed from it air, and repeat check. Play when rocking the rocker should not be felt.

In the absence of play in the pushers, the knock is caused by another reason.

Air removal

1. Immerse the tappet in clean diesel fuel.

2. Press the wire 4-5 times on the ball, removing the air.

3. Press the plunger. If a lot of resistance is felt, then the pusher is in a normal state, otherwise repeat pumping. If the air cannot be removed, replace the pusher. When finished, store the pusher in the working position.

4. Check the tightness of the hydraulic pusher on the MD998440. To do this, measure the time required for the plunger to move 1 mm, starting from its displacement by 0.2–0.5 mm.

This time should be 4–20 s. Otherwise, replace the hydropusher.