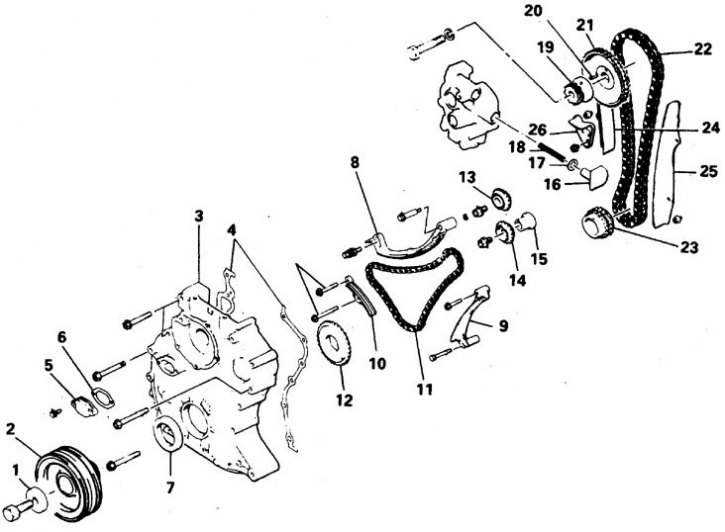

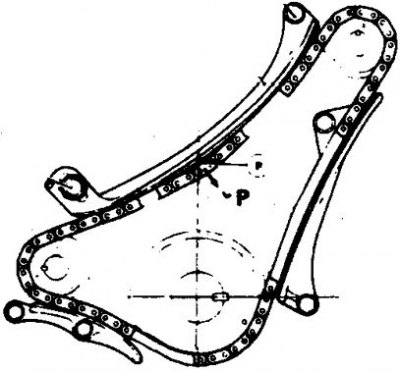

2.6L engine circuit

1. Washer; 2. Pulley; 3. Chain cover; 4, 6. Gasket; 5. Plug; 7. Oil seal; 8. Calm B; 9. Calm A; 10. Calming agent C; 11. Small chain; 12. Asterisk B; 13. Oil pump sprocket; 14. Asterisk of the left roller; 15. Sleeve; 16. Tensioner; 17. Seal; 18. Spring; 19. Gear; 20. Pin; 21. Camshaft sprocket; 22. Camshaft chain; 23. Crankshaft sprocket; 24. The damper from the side of the chain tension; 25. The damper from the side of the chain tension; 26. Sprocket holder

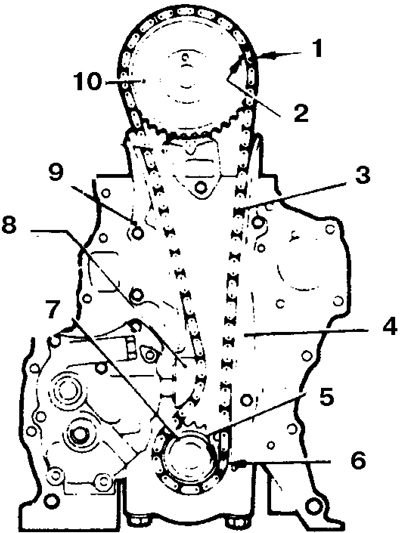

Chain alignment marks on 2.6L engine

1, 6. Anodized link; 2, 5. Label (pit); 3. Chain; 4, 9. Sedative; 7. Crankshaft sprocket; 8. Tensioner; 10. Camshaft sprocket

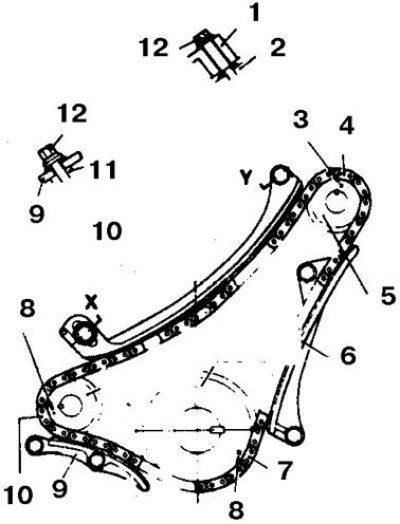

Combination of sprockets and small chain (2.6 l)

1, 6, 9. Sedative; 2. Cylinder block; 3, 8. Label; 4, 7. Anodized link; 5. Asterisk; 10. X-section; 11. Y section; 12. Bolt

Removing

1. Disconnect the battery from the ground.

2. Drain the liquid.

3. Disconnect the radiator hose and remove the top fan shroud.

4. Remove fan with clutch and store in proper working position.

5. Remove accessory belts.

6. Remove the fan pulley from the cooling pump.

7. Disconnect the heater hose from the cooling pump.

8. Turn away bolts, having paid attention to their arrangement, and remove the cooling pump.

9. Turn away a bolt and a puller compress a pulley of a crankshaft.

10. Remove the cylinder head cover.

11. Turn out from a head of cylinders 2 forward bolts of fastening of a cover of a chain.

12. Turn out bolts of fastening of the pallet screwed in a cover of a chain.

13. Turn away bolts and remove a cover, having destroyed consolidation by a sharp tool.

If the front part of the pan gasket was damaged when removing the cover, carefully cut this part flush with the cylinder block.

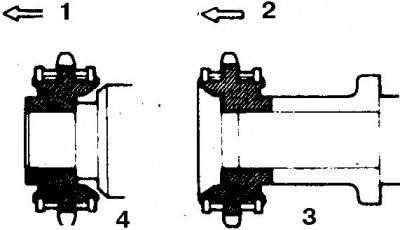

14. Replace the front oil seal by carefully pulling it out and pressing in a new one with the MD998376-01 or MB990938-01 mandrel.

15. Set the piston of the 1st cylinder to the TDC of the compression stroke (rocker arms should swing freely within the gap).

16. Remove the 3 dampers resting against the chain of the vibration damper roller, marking each of the mounting bolts.

17. Remove the small chain from the vibration damper roller and from the oil pump. If the chain does not give in, then turn away bolts and remove asterisks together with a chain. Remove the keys (if provided). Pay attention to the orientation of the stars.

18. Remove the 1st crankshaft sprocket.

19. Wire the tensioner plunger into the oil pump housing.

20. Turn away a bolt and remove an asterisk of a camshaft and a gear wheel of a drive of the distributor of ignition. You can also remove the chain along with the crankshaft and camshaft sprockets.

21. Remove dampers, save all bolts and washers in the same order.

Installation

1. Check the condition of the chain, if worn links are found, replace the chain.

Replace worn tensioner plunger with seal and spring.

Replace dampers if deep grooves have formed in them. Replace sprockets if visible wear on teeth

2. Install the left and right dampers.

3. Put the chain on the crankshaft and camshaft sprockets, aligning the marks with the anodized chain links. Put the sprocket on the crankshaft, and fasten the camshaft sprocket to the holder.

4. Put on the camshaft sprocket, passing the pin through the hole and tighten the bolt with a torque of 54 Nm.

5. Remove the wire from the tensioner and tension the chain.

6. Fit the small chain with the sprockets, lining up the marks and links with the distinctive color (install the stars without disturbing their previous location).

7. Put on gear B.

8. Put a small chain on the crankshaft sprocket, aligning the anodized link with mark 3.

Put the rest of the sprockets on the roller and oil pump, slightly tighten the bolts (1, 2 - to the chain; 3 - installation of an asterisk on the left roller; 4 - installation of an asterisk on the neck of the drive gear of the oil pump).

9. Turn both sprockets of the small chain and oil pump, set the place of the greatest slack at point P in the illustration.

10. Install the small chain guides and adjust the upper guide (IN) so that the gap between the chain and the damper is 0.2–0.8 mm. Tighten the bolt to 19 Nm.

11. Install all removed parts. When installing the covers, check the condition of the gaskets. Cut out part of the removed gasket and install, lubricating the joint with sealant. Tighten the chain cover bolts to 14 Nm, the crankshaft bolt to 119 Nm, the sump bolts to 5 Nm, and the front cylinder head bolts to 19 Nm. After starting the engine, listen for noises from the circuit side. If unusual noises are heard, stop the engine and check the chain installation and tension. When finished, adjust the accessory drive belts.