Idle speed and ignition timing are recommended to be adjusted together with subsequent mutual adjustment. When installing the ignition, be guided primarily by the data on the engine compartment plate.

2.0 and 2.6L engines

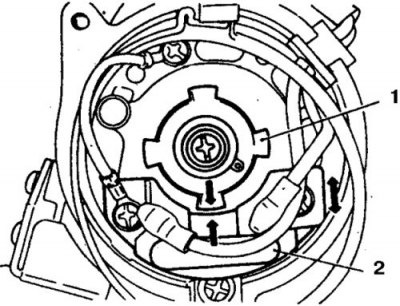

Ignition sensor adjustment on 2.0L engine

1. Rotor

2. Ignition block

1. Warm up the engine.

2. Disconnect all consumers, set the transmission to neutral position.

3. Connect a tachometer in accordance with the manufacturer's instructions and check the idle speed.

4. Connect the stroboscope according to the manufacturer's instructions.

5. Start the engine and point the light at the crankshaft pulley. At idle, the illuminated mark should be opposite the scale indicator on the front cover.

If adjustment is necessary, release the bolt and turn the distributor housing until the mark aligns with the pointer. Tighten the bolts and check the ignition setting again.

6. Stop the engine and disconnect a stroboscope.

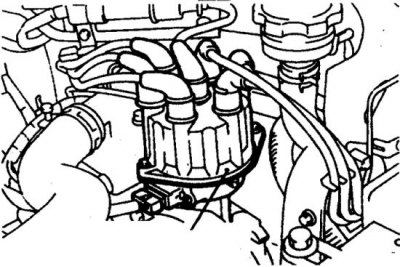

Engines 2.4 and 3.0 l (12 valve)

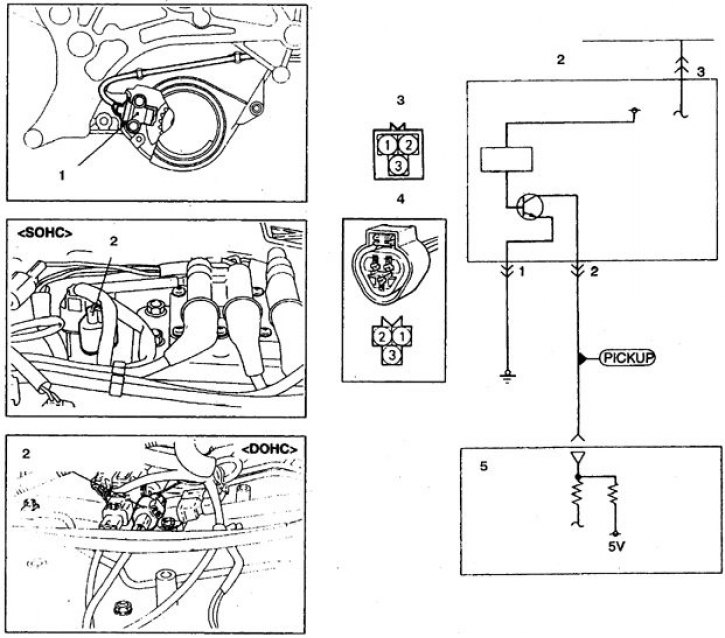

Crankshaft rotation sensor on 3.0L engine

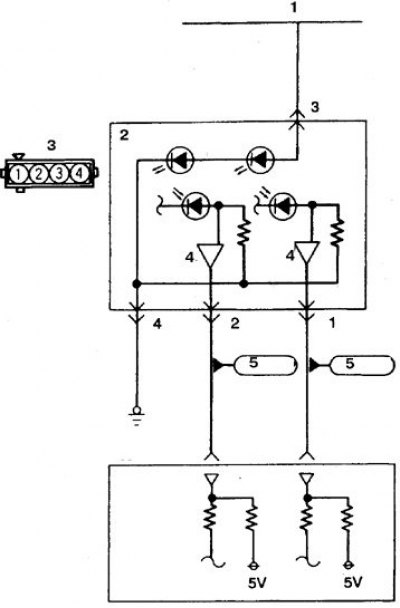

Scheme of switching on the crankshaft rotation sensor (12-valve 3.0L engine)

1. Injection relay; 2. Distributor; 3. Connector on the tester side; 4. Crankshaft rotation sensor; 5. Processing unit

1. Warm up the engine. Disconnect all consumers, set the transmission to neutral.

2. Stop the engine and connect the stroboscope according to the manufacturer's instructions.

3. Connect the pins of the engine speed sensor connector with paper clips (or filter, depending on the engine) and wires from the primary winding of the coil.

Connect a tachometer to the clip without opening the connector.

4. Start the engine and check the idle speed.

5. Stop the engine and turn off the ignition.

6. Connect to ground output for ignition installation.

7. Start the engine.

8. Point the strobe light at the crankshaft pulley. At idle, the ignition timing should be 3–7°BTDC.

9. If adjustment is necessary, loosen the fastening nut, turn the distributor housing and set the ignition timing. Tighten the nut carefully.

10. Stop the engine and remove the paper clip and ground strap.

11. Start the engine and check the ignition timing again. The ignition timing should be 8°BTDC on a 2.4L engine and 15°BTDC on a 3.0L engine.

A slight difference from these values is allowed, which may be due to the processor mode during basic ignition tuning.

Engine 3.0L (24 valve) and 3.5 l

Scheme of switching on the crankshaft rotation sensor (3.0L 24-valve engine and 3.5L twin-shaft engine)

1. Crankshaft rotation sensor; 2. Sensor connector; 3. Connector on the tester side; 4. Connector on the wiring side; 5. Processing unit

1. Warm up the engine. Disconnect all consumers, set the transmission to neutral.

2. Stop the engine and connect the stroboscope according to the manufacturer's instructions.

3. Point the strobe light at the crankshaft pulley. At idle, the ignition timing should be 2–8°to TDC.

4. Start the engine and check the idle speed, which should be 600-800 rpm. Adjust if necessary.

5. Stop the engine and turn off the ignition.

6. Connect to ground output for ignition installation.

7. Start the engine.

8. Point the strobe light at the crankshaft pulley. At idle, the ignition timing should be 2–8°before TDC.

9. If necessary, adjust the position of the crankshaft rotation sensor.

10. Stop the engine and remove the paper clip and ground strap.

11. Start the engine and check the ignition timing again. The ignition timing must be 15°BTDC for both engines. A slight difference from these values is allowed, which may be due to the processor mode during basic ignition tuning.