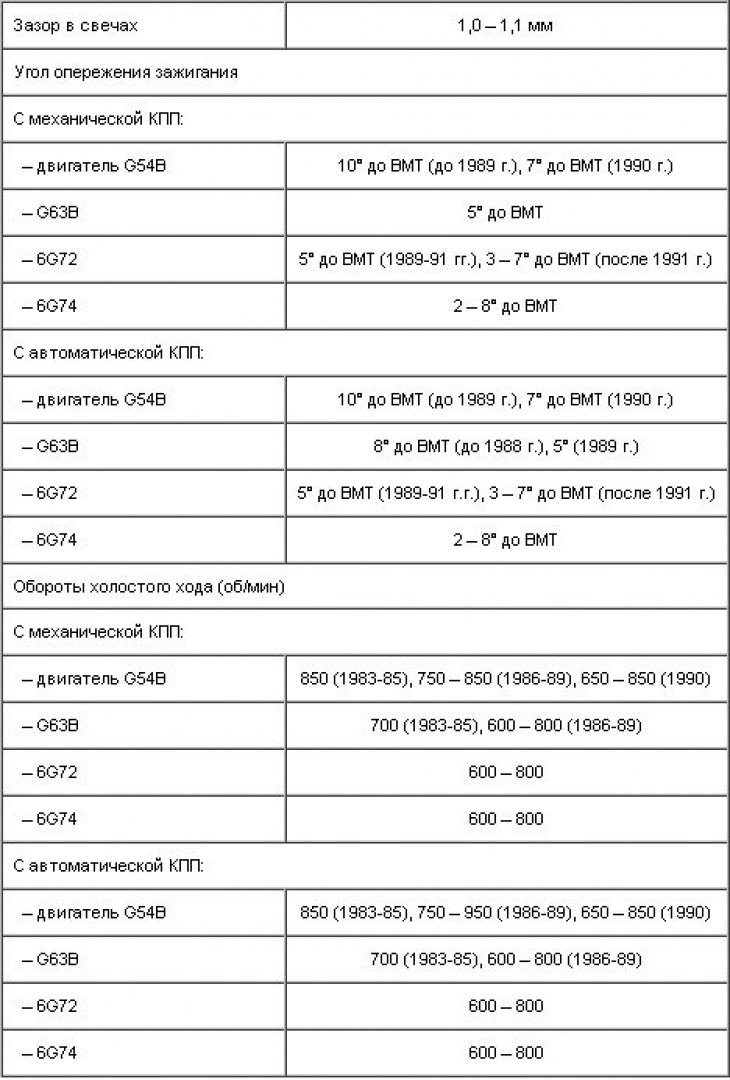

Carburetor engines

Attention! The mixture adjustment screw is closed with a plug, which should be cracked only if the carburettor is being repaired.

1. Remove the carburetor. The mixture ratio adjustment screw is located at the base of the carburetor, next to the crankcase breather hose. Install the carburetor base up.

2. Drill a hole with a diameter of 2 mm in the tide of the carburetor base. This hole must pass under the plug and cross the inner well of the screw.

Ream the hole with a 3.2 mm drill.

3. Knock out the plug with a beard. Install the carburetor with all hoses connected.

4. Start the engine and warm up at idle. Turn off all onboard consumers. Set the transmission to neutral. Turn off the ignition, disconnect the battery from the ground for 5 seconds. Disconnect the oxygen sensor wire.

5. Increase the speed to 2000-3000 rpm, after 5 seconds, switch the engine to idle for 2 minutes.

6. Connect a tachometer. With the engine idling, check the CO content with an analyzer, which should be 0.1-0.3%. Adjust if necessary by turning the screw. If during adjustment the speed has changed by 100 rpm, then adjust the speed and composition of the mixture so that both indicators correspond to the norm. Stop the engine, connect the oxygen sensor wire and install the plug.

Injection engines

The quality of the mixture is adjusted automatically.

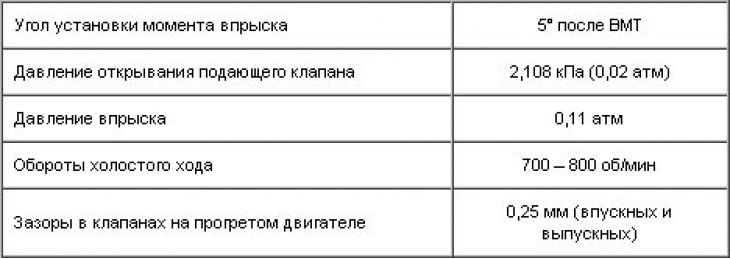

Diesel adjustment data

Adjustment data for carburetor engines