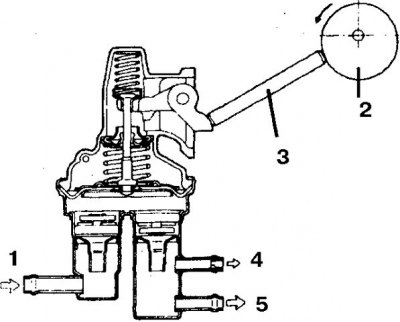

2.0L Engine Mechanical Fuel Pump

1. From the filter; 2. Camshaft; 3. Pusher; 4. Fitting of the return gas pipeline; 5. To the carburetor

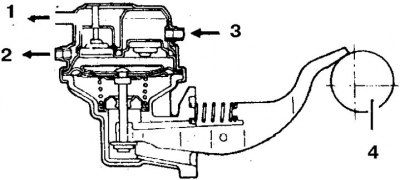

2.6L Engine Mechanical Fuel Pump

1. Fitting of the return gas pipeline; 2. To the carburetor; 3. From the filter; 4. Camshaft

It is installed on all vehicles with 4-cylinder engines. The pump is mounted on the side of the cylinder head. The pump is driven from the camshaft eccentric through a pusher or lever.

Removal and installation

1. Disconnect the battery from the ground. Remove the air filter (on car parts).

2. Set the piston of the 1st cylinder to the TDC of the compression stroke. To do this, turn the crankshaft clockwise until the mark on the pulley or damper aligns with the lug on the cylinder block. Remove the valve cover and check the valve springs of the 1st cylinder. If both springs or at least one are compressed, then turn the crankshaft 1 turn. If the rocker arms sway, then the piston of the 1st cylinder is at TDC of the compression stroke.

3. Disconnect fuel hoses.

4. Turn away bolts and remove the pump, a spacer, linings and a pusher.

5. Installation is carried out in the reverse order. Tighten the pump bolts to 16 Nm.

Vehicle check

1. Disconnect the pump hose from the filter and connect the vacuum gauge.

2. Disconnect the coil wire and have an assistant turn on the starter.

3. With each stroke of the eccentric to the vacuum gauge, it should show a significant vacuum, without sharp jumps. If surges or low vacuum are observed, replace the pump.

Checking the removed pump

1. Replace the pump if fuel or oil leaks through the hole in the top of the housing.

2. Check up a condition of an end face of a pusher or a persistent surface of the lever. If wear is found on the end face, remove the cover and check the condition of the surface of the camshaft eccentric. In case of severe wear of the end face on the pump side, replace the pusher and pump.