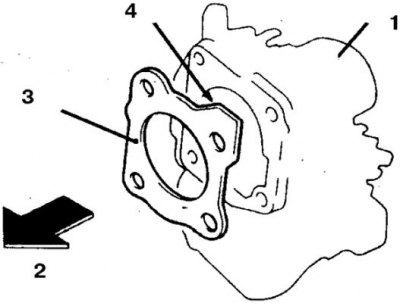

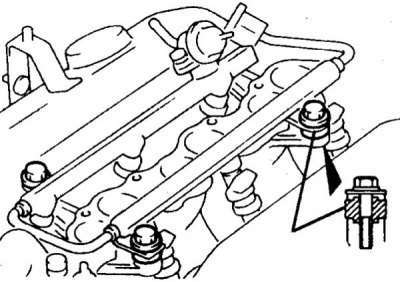

Gasket Orientation on Throttle (2.4 l)

1. Pipe; 2. To the collector; 3. Gasket; 4. Ledge

2.4L engine

Removing

1. Decompress and disconnect the battery from ground.

2. Drain the liquid.

3. Remove the throttle (see subsection 8.2.3).

4. Disconnect connectors from injectors.

5. Disconnect the fuel lines from the fuel distributor.

6. Remove the pressure regulator.

7. Remove the fuel distributor, get the nozzles, insulators, seals and rings. Keep nozzles free of dust and dirt.

Installation

1. Replace all gaskets and seals of injectors and other removed units.

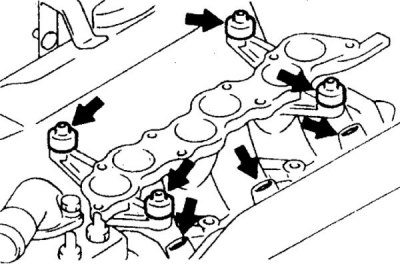

2. Set the nozzles by turning left and right.

3. Tighten bolts and nuts with the moments specified in an illustration.

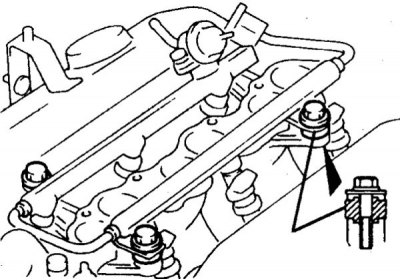

3.0 and 3.5L engines

Removing

1. Decompress and disconnect the battery from ground.

2. Drain the liquid.

3. Remove the intake manifold.

4. Disconnect the fuel lines from the fuel distributor.

5. Remove the pressure regulator.

6. Disconnect connectors from injectors.

7. Turn away bolts of fastening of an inlet pipe (single fuel distributor for 2 heads).

8. Remove the fuel distributor with nozzles.

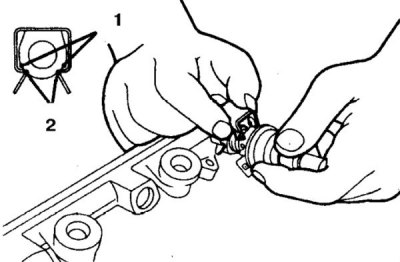

9. Get nozzles. On the 3.5 liter engine, the injectors are attached with brackets (1 - bracket; 2 - nozzle).

Installation

1. Replace all insulators and nozzle seals, gaskets from other removed units, guided by the illustration.

2. Tighten bolts and nuts.

Checking the injectors

The nozzles are checked by listening to clicks through a stethoscope or a long screwdriver, by measuring the electrical resistance of the winding, which should be 13-16 ohms at 20°C, and also by the torch on the stand (carried out in a car service).

Attention! It is forbidden to test the injectors with 12 V battery voltage, otherwise they will fail.