Diesel timing belt

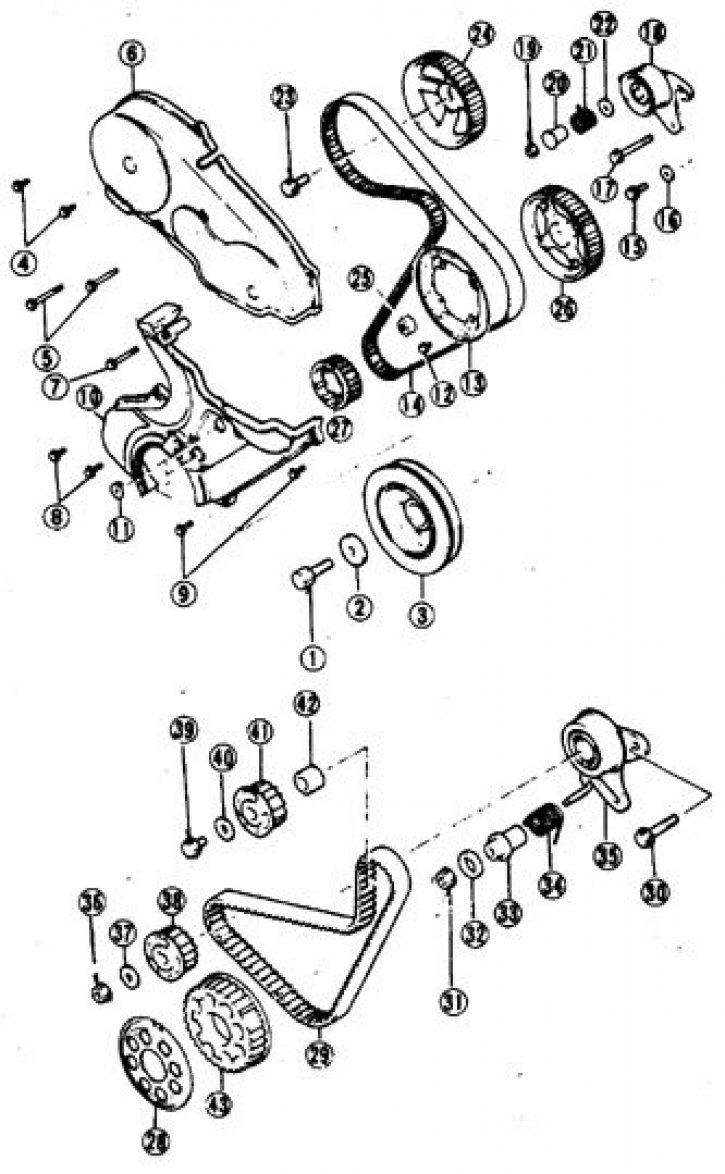

1, 4, 5, 7, 8, 9.12, 13, 15, 17, 23, 30, 39. Bolts; 2. Washer; 3. Calm; 6. Top cover; 10. Bottom cover; 11. Plug; 14. Belt; 16. Washer; 18. Tensioner; 19, 25, 31, 36 Nut; 20, 33, 42. Sleeve; 21. Spring; 22, 37, 40. Washer; 24. Camshaft sprocket; 26. Fuel pump sprocket; 27. Crankshaft sprocket; 28. Flange; 29. Belt B; 32. Spring; 34. Spring; 35. Belt tensioner B; 38, 41. Balance shaft sprocket; 43. Asterisk In the crankshaft

Removing

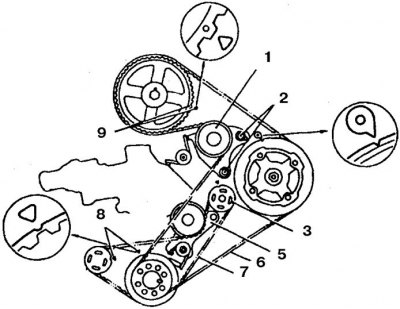

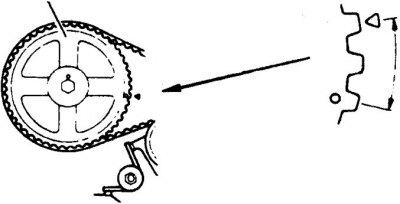

Diesel belt alignment marks

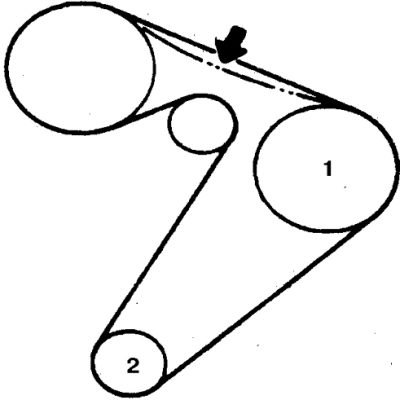

1. Tensioner; 2. Bolt; 3, 7. Vibration damper roller sprocket; 4. Tensioner B; 5. Belt; 6. Belt B; 8, 9. Tags

1. Disconnect the battery from the ground.

2. Remove the drive belts, unscrew the bolts and remove the coolant pump and crankshaft pulleys.

3. Remove the top cover paying attention to the location of the bolts.

4. Set the piston of the 1st cylinder to the TDC of the compression stroke. From now on, rotation of the crankshaft is not allowed.

5. Remove the crankshaft pulley.

6. Remove the lower belt cover.

7. Loosen the tensioner, move to the cooling pump, tighten the bolts.

8. Remove the camshaft and fuel pump sprockets, preventing the shafts of these units from rotating.

9. Remove a gear belt.

10. If the vibration damper belt is removed, fix the rollers by removing the plug on the right side and inserting a rod (screwdriver with a diameter of 8 mm). On the left side, remove the cover and insert a thick rod (key extension).

11. Mark and remove roller sprockets.

12. Check up a condition of belts, at detection of any defects replace.

Installation

1. Install the vibration damper roller sprocket on the crankshaft, put on the pulley, tighten the bolt with a torque of 70 Nm.

2. Install the fuel pump sprocket, bushings (cone inward) and roller stars. Tighten the sprocket bolts to 38 Nm. (1 - tension side; 2 - cooling pump).

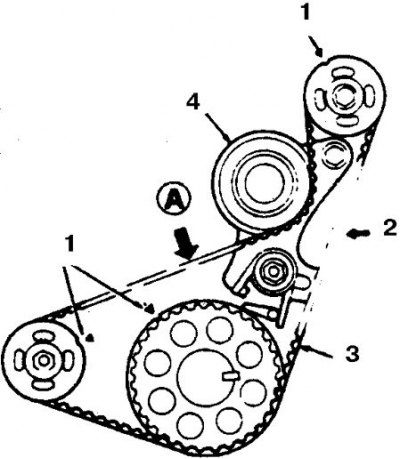

3. Align the marks on the roller sprockets (1 - marks; 2 - tension side; 3 - belt B; 4 - tensioner B). Check the roller belt tension at A.

4. Wear a belt (IN) so that there is slack on the side against which the tensioner rests.

5. Check the alignment of the marks by pressing on the belt with your finger. Without loosening the tension, loosen the tensioner bolt and nut. Tighten the nut first, then the bolt.

6. Check roller belt tension (deflection 5–7 mm).

7. Check the alignment of the marks of the camshaft belt and pump sprockets and put on the belt by pulling it between its crankshaft and the pump (during installation, the assistant holds the pump sprocket).

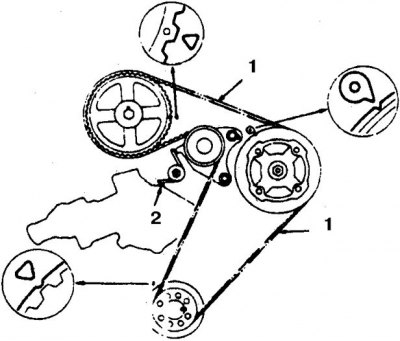

8. Loosen the tensioner bolts, and take up the slack in the belt. Tighten the bolt in the tensioner slot, then the axle bolt. Check the fit of the belt to the camshaft sprocket (2), the belt can pass with 10 o'clock loosening in the sector. Make sure the belt does not interfere with adjacent parts (1 - pump sprocket).

9. Check the alignment of the asterisk marks, if necessary, remove the belts and set the asterisks.

10. Turn the crankshaft so that the camshaft sprocket moves 2 teeth from the alignment mark and return it back, setting the sprocket to its previous position.

11. Check belt tension (deflection should be no more than 4–5 mm).

12. Install covers and other removed parts. Tighten the crankshaft pulley bolt to 64–73 Nm.