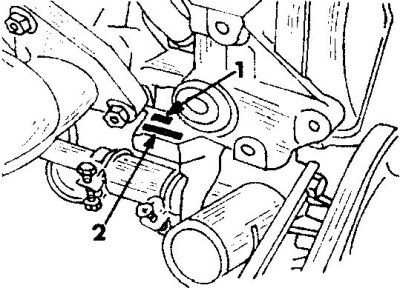

Location of the engine number on a diesel engine

1. Engine type

2. Serial number

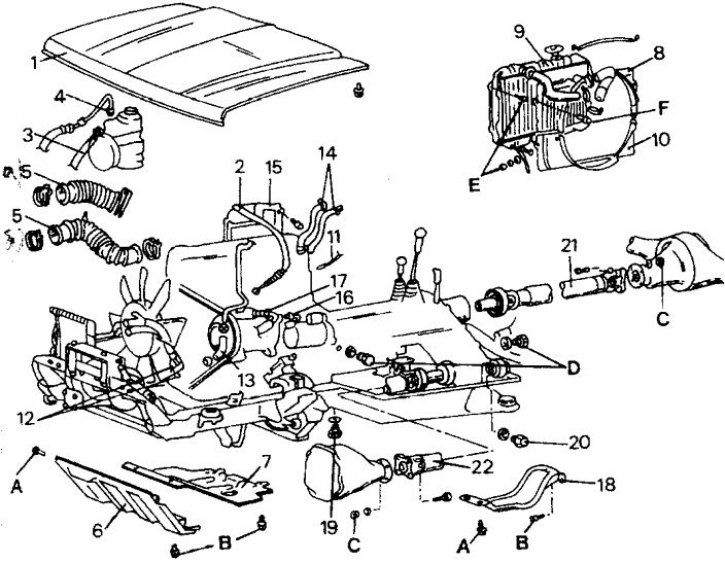

Removal and installation of diesel engine with transmission

1. Hood; 2. Throttle control cable; 3. Return hose, hydraulic steering system; 4. Pressure hose, hydraulic steering system; 5. Air hose (A) diesel engine, (b) turbodiesel engine; 6. Protective pallet of the engine; 7. Protective tray; 8. Top facing of a radiator; 9. Radiator; 10. Lower facing of a radiator; 11. Cable harness; 12. Oil cooler hoses; 13. Vacuum hose of the hydraulic booster of the brake system; 14. Heater hoses; 15. Heat shield; 16. High pressure hose, air conditioner; 17. Low pressure hose, air conditioner; 18. Transfer case protective tray; 19. Oil drain plug of transmission; 20. Oil drain plug of the transfer case; 21. Rear driveshaft; 22. Front driveshaft

Main tightening points: A = 18–25 Nm; B = 10–13 Nm; С = 30–35 Nm; D = 30–35 Nm; E = 8–11 Nm; F = 3–5 Nm

The engine is removed along with the gearbox. The figure shows the parts to be removed in the order in which they were removed. When describing the work, instructions are given only for work operations related to the removal of parts.

1. Open the engine compartment hood. Drain the coolant. The drain plug is located on the underside of the radiator. The second plug is screwed into the cylinder block.

2. Outline the contours of the hinges of the hood of the engine compartment with a pencil and unscrew the bolts of the hood on the hinges. Remove the hood with an assistant and put it in a protected place.

3. Disconnect and remove the battery.

4. Disconnect the gas control cable from the high pressure fuel pump.

5. If there is a power steering, disconnect the return and pressure hoses. Lower the hoses into a container underneath to drain the fluid.

6. Remove the air hose.

7. Place the front of the car on stands. Keep in mind that the weight of the vehicle is significant and the stands must be strong enough to support this weight. The soil must be firm enough so that the coasters do not sink into the soil. Turn away from the forward party of the car protective pallets.

8. Remove the top facing of a radiator, a radiator and the bottom facing of a radiator.

If an automatic transmission is installed, disconnect the oil cooler hoses before removing the radiator. If there is a radiator for intake air, disconnect its supply. Substitute a container under the transmission to drain the resulting fluid.

9. Disconnect the cable harness from the motor.

Disconnect all other cables from the engine as follows: on the left side of the engine, disconnect the engine ground wire and the starter cable; disconnect the wires from the high pressure fuel pump (indicated by an arrow) and glow plugs (connectors are indicated by an arrow).

10. If an air conditioner is installed, disconnect the temperature switch cable (near a drain plug) and disconnect the magnetic clutch connector.

11. On the right side of the engine, disconnect the alternator harness. Disconnect the ground wire from the underside of the filter and from the oil pressure switch and oil pressure gauge sensors.

12. Disconnect the oil cooler hoses. Drain the oil first.

Seal the disconnected hoses and openings in the engine with appropriate plugs to prevent oil from entering.

13. Disconnect the vacuum hose from the brake booster.

14. Disconnect the heater hoses from the connection points on the bulkhead of the engine compartment.

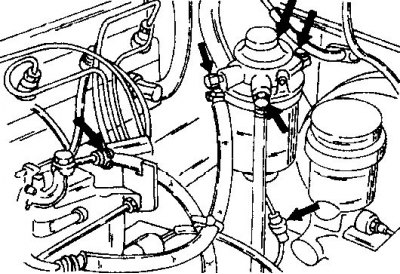

15. Turn away under the car the protective pallet of a distributing box. Substitute one vessel under the gearbox, and the second under the transfer case and remove both oil drain plugs. Drain the oil completely and tighten the plugs again. Plug tightening torque from 30 to 35 Nm.

16. Turn away flange fastenings of back and forward cardan shafts.

17. If the engine is equipped with a cable winch, remove the drive shaft, cotter pin and shift cable.

18. Turn away a flange of a forward pipe of the muffler from a final collector.

19. Disconnect the speedometer flex, reversing light switch wires, and all wheel drive warning light harness.

20. Unscrew the clutch slave cylinder from the gearbox side without disconnecting the hoses. Secure the cylinder with wire from the underside of the vehicle, being careful not to strain the hose.

21. Remove the engine cross member. Remove the engine mount bolts first, and then remove the lower cross member mounting bolts. When doing this, the engine and gearbox must be supported appropriately, otherwise the rear side will lower when the cross member is released. Unscrew the plate.

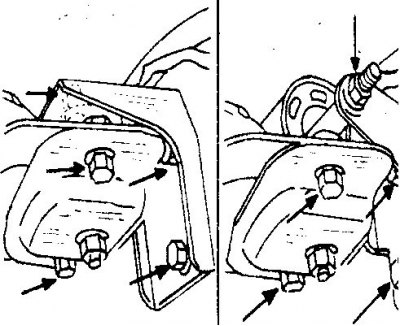

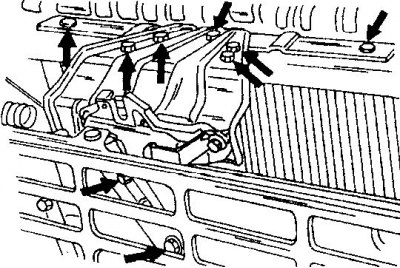

22. Raise the gearbox and transfer case with a roller jack and remove the suspension bracket and transfer case rubber support. Then unscrew the side plate. Unscrew the suspension bracket from the transfer case (the arrows indicate the bolts of the transfer box suspension bracket).

23. Remove the shift lever from the gearbox.

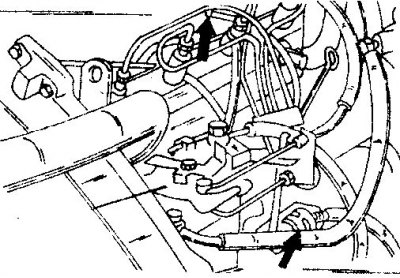

24. Remove fuel hoses and fuel filter (the arrows indicate the connections on the fuel filter). Open the fuel tank cap to relieve pressure in the fuel tank. Insert screws of the appropriate diameter or appropriate plugs into the hoses to prevent dirt from entering.

Disconnect the wire connector for the condensation indicator.

25. Remove the bolts (indicated by arrows). This releases the locking hook of the engine compartment hood and the connecting plate (arrow)

26. Hook the engine and gearbox with cable loops and chains to a chain hoist or crane. Be aware of the weight of the engine. Position cable loops or chains on the engine so that the engine is tilted front side up and the gearbox hangs down.

27. Raise the power unit just enough to relieve the engine mounts and remove the bolts. Remove the engine mounts from the suspension brackets.

28. Slowly pull the power unit out of the engine compartment. At the same time, make sure that no wires, hoses or tubes are caught, and that connections are not disconnected. If the gearbox gets stuck in the tie rods, run the gearbox from the underside of the vehicle over the tie rods.

29. After removing the power unit, the gearbox can be separated from the engine. To do this, remove the starter and unscrew the bolts connecting the gearbox to the engine. Take the gearbox away from the engine in a horizontal position, without loading the input shaft with the weight of the gearbox, as it may be damaged or bent by the clutch disc.

30. Before installing the engine and transmission, check all engine mounts.

Rubber mounts with cracks or other damage must be replaced. The same applies to soft engine mounts.

31. Check for damage, cracks or ruptures in fuel hoses, heater hoses and water hoses. In most cases, damage is observed in places under the fastening collars, which are often very difficult to see, even when the collar is removed.

32. Check up absence of damages, cracks and gusts of fuel hoses, hoses of a heater and water hoses. In most cases, damage is observed in places under the fastening collars, which are often very difficult to see, even when the collar is removed.

33. The engine is installed in the reverse order.

34. At installation connect the engine and a transmission with bolts and establish a starter. And here, remember that you cannot load the input shaft with the weight of the box when connecting the gearbox. Tighten the bolts to the specified tightening torque.

35. Lower the engine with transmission into the engine compartment, install the engine mounts, and lower the weight of the power package onto the engine mounts. Tighten the bolts to the specified tightening torque.

36. Connect the front and rear driveshafts.

37. Pour the prescribed amount of oil into the gearbox and transfer case. Filling capacities are shown in the tables of adjustments and dimensions. It should be borne in mind that in the presence of a winch, more oil must be poured into the transfer case.

38. Connect air conditioning hoses. After work, put the air conditioner under pressure.

39. Install the radiator and fill in the coolant.

40. Connect the pressure and return hoses of the hydraulic steering system and bleed the air from the system.

41. Connect and adjust the throttle cable.

42. Place the engine compartment hood, lining up the hinges according to the marks made during removal with a pencil, and tighten the hinge bolts. Check how the engine compartment hood closes.

43. When connecting the front muffler pipe to the exhaust manifold, replace the gasket.

44. After installing the engine, fill it with the prescribed amount of oil.

Start the engine and check for coolant, fuel and oil leaks.