Timing belt tension control on a diesel engine

The deflection of the belt should be 4–5 mm.

1. Turn away bolts of fastening of the top protective casing of a gear belt and remove a casing. Rotate the crankshaft until the piston of the first cylinder is at top dead center. Since the head cover is removed, the position of the crankshaft must be controlled by the crankshaft belt pulley.

The notch on the crankshaft pulley should be opposite the top dead center mark on the bottom cover of the timing case.

To rotate the crankshaft, put a spanner wrench on the center bolt of the crankshaft pulley.

2. Loosen the belt tensioner mounting bolts two turns.

3. Use a spanner wrench to turn the crankshaft clockwise from the top dead center position by two teeth on the camshaft pulley. The tensioner spring begins to act and sets the belt to a new position.

4. Tighten the tensioner fastener. To ensure that the tension of the toothed belt does not change, first tighten the bolt in the slot, then the lower bolt. Tighten both bolts to a tightening torque of 22–30 Nm.

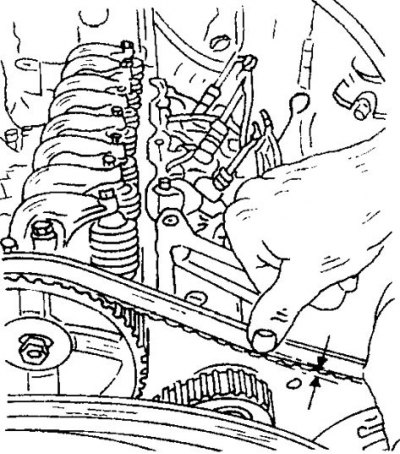

5. For reliability, check the toothed belt tension again. To do this, press your finger on the belt, as shown in the figure. If at the same time the belt has a deflection of 4-5 mm, it is adjusted correctly and removed parts can be installed.