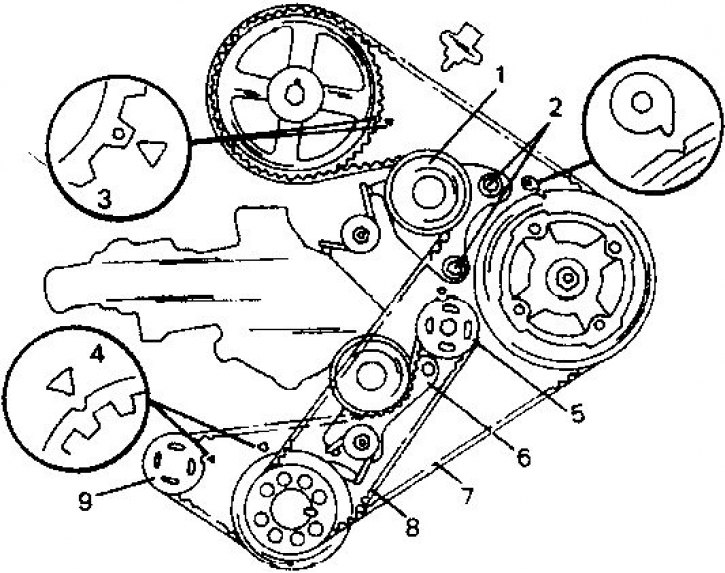

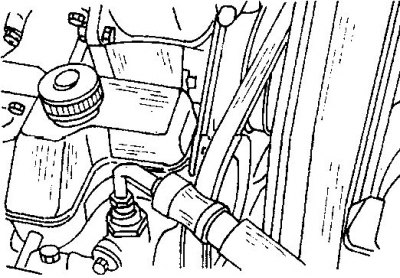

Exhibition of timing marks on a diesel engine

1. Toothed belt tensioner; 2. Mounting bolts; 3. Label on the distribution shaft; 4. Mark on the toothed pulley of the compensation shaft; 5. Gear pulley of the compensation shaft; 6. Tensioner drive belt compensation shaft; 7. Toothed timing belt; 8. Toothed belt compensation shaft; 9. Compensation shaft drive pulley

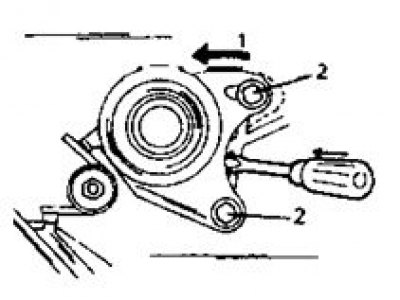

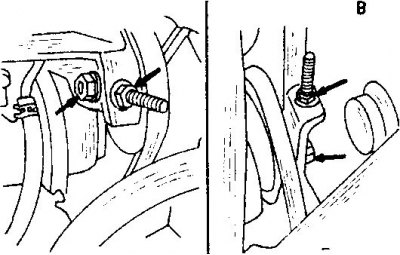

Removing the toothed belt

Place the tension roller in the direction of the arrow.

1. Water pump

2. Nut

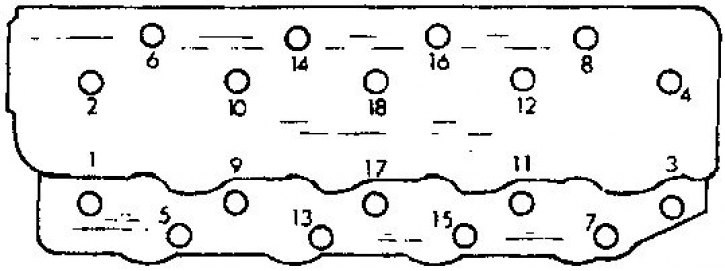

Cylinder head bolt loosening sequence

Bolts are tightened in reverse order.

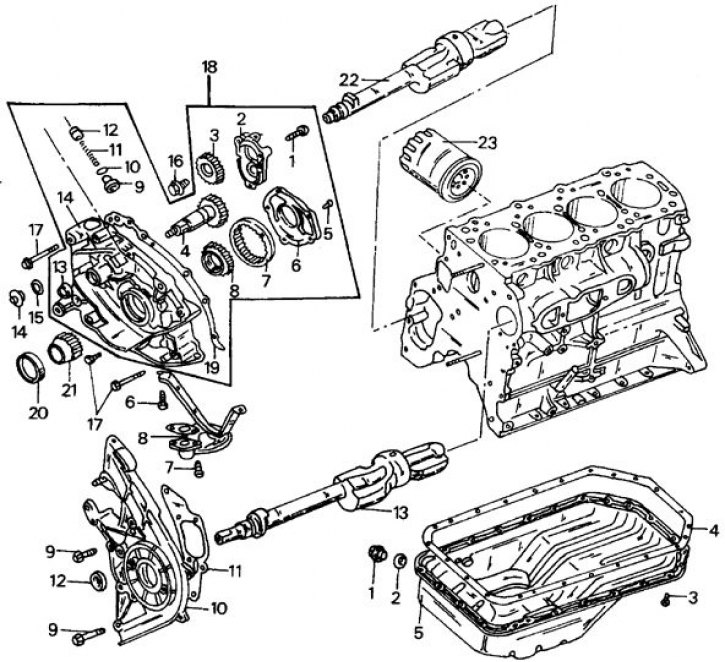

Lower case

1. Oil drain plug; 2. Gasket; 3. Oil pan bolts; 4. Oil sump gasket; 5. Oil sump; 6. Bolt; 7. Bolt; 8. Mesh oil pickup tube; 9. Front housing bolts; 10. Front top case; 11. Housing gasket; 12. Oil seal; 13. Left compensation shaft; 14. Threaded plug; 15. Sealing O-ring; 16. Mounting bolts; 17. Mounting bolts; 18. Front lower case; 19. Lower housing prokdaka; 20. Front oil seal; 21. Oil pump gear shaft; 22. Right compensation shaft; 23. Oil filter

Details of the front lower case (18): 1. Mounting bolts; 2. Cover of the belt pulley of the compensation shaft; 3. Belt pulley of the compensation shaft; 4. Drive gear; 5. Bolt; 6. Oil pump cover; 7. Oil pump outer gear; 8. Oil pump inner gear; 9. Safety valve plug; 10. Gasket; 11. Safety valve spring; 12. Oil safety valve; 13. Oil seal; 14. Front bottom case

Attention! The sequence of dismantling the engine as part of the overhaul is given.

1. Drain the engine oil.

2. Remove all attachments from the engine. If you have any doubts about performing a certain job, read the appropriate section of the book.

3. Remove the clutch. To do this, lock the flywheel accordingly.

Make a punch mark on the flywheel and on the clutch to ensure that the parts are installed in the same position when they are reinstalled. Loosen the clutch bolts evenly around the circumference before finally unscrewing them.

4. Loosen the alternator mounting bolts and remove the drive V-belt. Then remove the generator. Also unscrew the belt tensioner from the cylinder block.

5. Remove the power steering pump drive belt. To do this, unscrew the bolt shown in the figure and the adjusting rod bolt and remove the belt.

6. Remove the A/C compressor drive belt (B - on diesel engines).

To do this, loosen the nuts on the tensioner just enough to remove the drive belt. Unscrew the belt pulley fastening in the kit.

7. Remove the radiator fan and viscous coupling from the front of the engine, as well as the water pump belt pulley.

8. Remove the top half of the timing cover along with the gasket.

9. Turn away two bolts of a cover of a head of cylinders and remove a lining, and also semicircular consolidation from a cover or from a head of cylinders.

10. While holding the crankshaft from turning, loosen the crankshaft pulley bolt. Remove the belt pulley. To do this, rest on opposite sides under the belt pulley with two mounts. Do not damage the parts.

11. Turn away the bottom half of a cover of a drive of the gas-distributing mechanism and remove linings from the left and right sides.

12. Rotate the engine until the piston of the first cylinder is at top dead center. To check the correct installation of the crankshaft, grasp both rocker arms of the first cylinder with your thumb and forefinger and shake them in different directions. If both rocker arms have gaps, then the crankshaft is set correctly. In this case, the marks on the engine take the position shown in Fig. Exhibition of timing marks on a diesel engine.

13. Chalk the direction of travel on the back side of the toothed belt, as well as the drive belt of the compensation shafts if the belts will be reinstalled.

14. Loosen both bolts and wring out the toothed belt tensioner pulley to the water pump with a screwdriver (see fig. Removing the toothed belt). As soon as the belt loosens, tighten the nut so that the tension roller cannot return to its original position.

15. Remove the toothed belt and drive belt from the toothed pulleys. After that, the engine must not be turned until the cylinder head is unscrewed. Store both belts in a protected area to keep them free from oil or grease. Don't bend the straps.

16. Remove the rocker shaft from the cylinder head.

17. Turn away covers of bearings of a camshaft and pull out a camshaft from a head of cylinders. Bearing caps sit on centering pins. A firmly seated cover can be moved with light blows with a rubber mallet. If required, remove the camshaft sprocket.

18. Turn away bolts of a head of cylinders for several passes in the sequence specified in fig. The sequence of loosening the cylinder head bolts. A special wrench head is used to loosen the bolts. If necessary, pry off the cylinder head with a plastic or rubber mallet. Never insert a screwdriver between the cylinder head and the cylinder block to pry the head away from the block.

19. Remove and discard the cylinder head gasket, regardless of the gasket's appearance. Immediately clean the surface of the cylinder head from seal residues.

20. Turn away an oil case.

21. Remove the front housing, articulated shafts and oil pump as follows.

22. Turn away the forward top case and remove a lining. Immediately press out the oil seal from the back of the upper housing. Pull out the left compensation shaft.

23. Unscrew the plug from the front lower housing and insert a screwdriver with a shaft diameter of 8 mm into the hole, thereby blocking the compensation shaft from turning.

24. Turn away a bolt of fastening of a driving gear wheel of a compensation shaft. If the shaft is in position, then it is kept from turning and the bolt is released. Press the belt pulley off the shaft, resting on opposite sides with two pry bars.

25. Turn away bolts and remove the bottom case. It is necessary to unscrew seven bolts.

26. Disassemble the bottom case (see fig. lower case). This includes the oil pump, balancer shaft pulley and both oil seals. Unscrew the filter mesh of the oil pick-up tube from the bottom of the crankcase. If both gears of the oil pump are removed, they should be marked with a core before being pulled out to ensure their subsequent installation in the same position. Gaskets can be immediately discarded, as they must be replaced. To remove the oil pump drive gear, you can unscrew the cover of the compensation shaft belt pulley.

27. Unscrew the oil filter from the side on the cylinder head with a special key.

If there is no special key, you can drive a screwdriver into the oil filter from the side and use it as a lever to unscrew the filter.

28. All other work is carried out in the same way as on gasoline engines.

Pay attention to the position of the main bearing caps as some have oil grooves while others do not.

29. Both end bearings have lubrication grooves, but their position must be marked (in the crankcase or on the bearing shells).