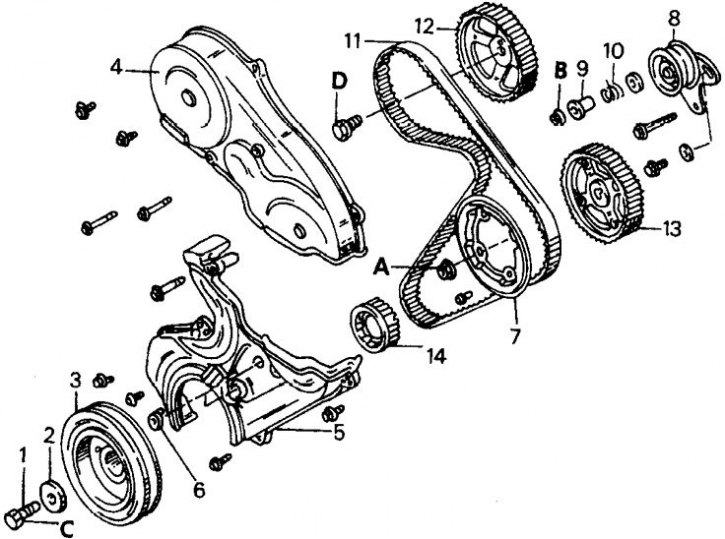

Camshaft Drive and High Pressure Fuel Pump Parts

1. Crankshaft pulley bolt; 2. Special washer; 3. Belt pulley crankshaft; 4. Upper toothed belt guard; 5. Lower toothed belt guard; 6. Plug; 7. Flange; 8. Timing belt tensioner; 9. Distance sleeve; 10. Toothed belt tensioner spring; 11. Toothed belt; 12. Camshaft pulley; 13. Belt pulley for high pressure fuel pump; 14. Crankshaft pulley; A = 80–90 Nm; B = 22–30 Nm; С = 170–190 Nm; D = 65–75 Nm

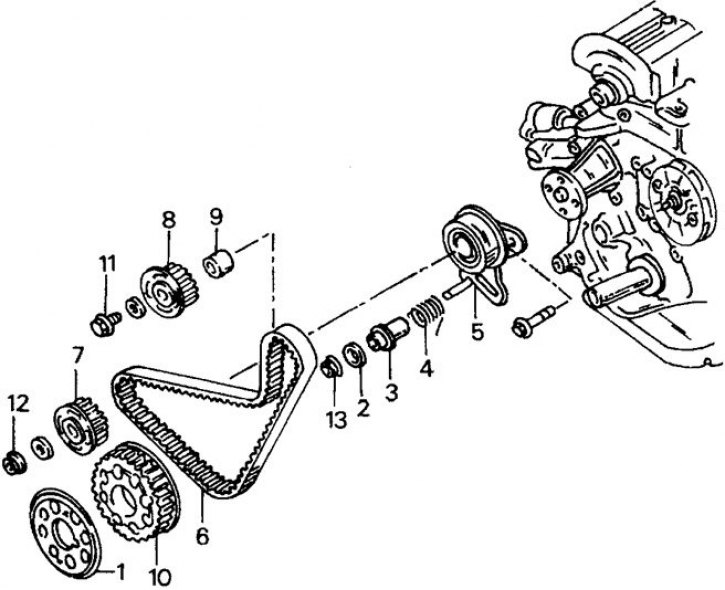

Lower Timing Belt Drive Parts

1. Flange; 2. Gasket; 3. Remote sleeve; 4. Toothed belt tensioner spring; 5. Timing belt tensioner; 6. Lower toothed belt; 7. Drive gear of the right compensation shaft; 8. Drive gear of the left compensation shaft; 9. Distance sleeve; 10. Crankshaft pulley; 11. Bolt, 34–60 Nm; 12. Bolt, 34–40 Nm; 13. Nut, 22–30 Nm

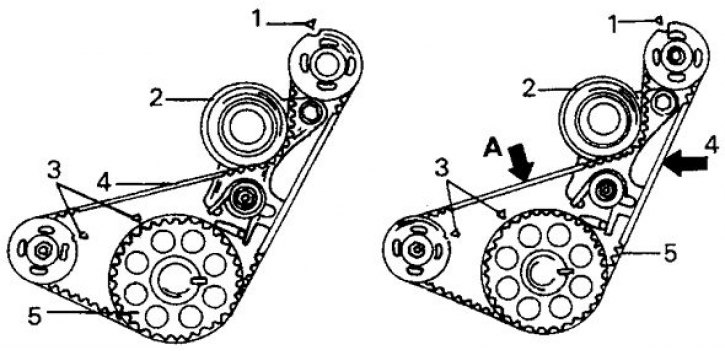

Lower toothed belt overlay (belt "IN")

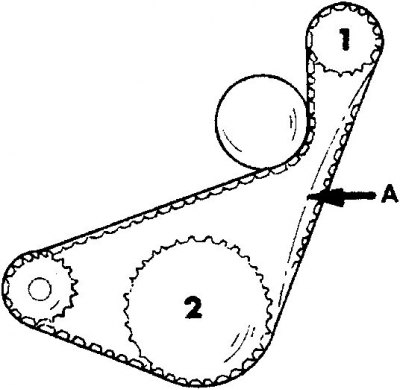

1. Label on the compensation shaft; 2. Timing belt tensioner; 3. Marks on the crankshaft sprocket and on the compensation shaft; 4. Toothed belt "IN"; 5. Crankshaft pulley

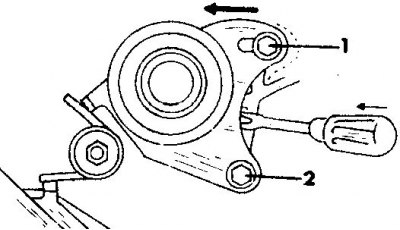

Installing the toothed belt tensioner

1, 2. Bolts

To the timing belt tension

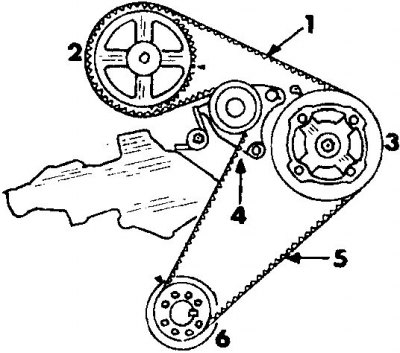

1. Belt tension side; 2. Camshaft pulley; 3. High pressure fuel pump drive gear; 4. Timing belt tensioner; 5. Belt tension side; 6. Crankshaft pulley

The following figures show the drive on a motor without compensation shafts.

In the following description, the toothed belt for the drive of the compensation shafts will be referred to as the belt "IN". In the description, the starting point is that all parts of the timing mechanism drive have been removed and must be installed.

Installation

1. Put a toothed pulley on the end of the crankshaft.

2. Install spacer. The bevelled side must face the compensation shaft. Incorrect installation can damage the toothed belt.

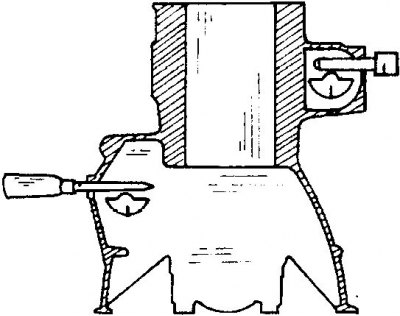

3. Place both drive gears on their respective shafts and tighten the bolt on one shaft and the nut on the other shaft to a torque of 34-40 Nm. Keep the shafts from turning. To do this, unscrew the plug on the right side and insert a screwdriver, and on the left side, unscrew the cover and insert a metal rod.

4. Install the toothed belt tensioner "IN", tensioner spring and spacer. Install the washer and hand tighten the nut.

5. Apply toothed belt "IN" (see fig. Lower toothed belt overlay (belt "IN")). Align the marks on the crankshaft sprocket with the marks on both countershaft drive gears. Apply the toothed belt, while ensuring the tension on the right side of the belt. When reinstalling the removed toothed belt, it must be applied in the same position.

6. Press your finger on the toothed belt in place "A" and check the labels again. If the marks are off, remove the belt again and turn the corresponding pulley one tooth to the right or left.

7. Loosen the toothed belt tensioner nut one or two turns to allow the toothed belt tensioner spring to press the tensioner against the toothed belt. Press the tension roller in the direction of the arrow. After that, first tighten the nut (1), and then bolt (2).

8. Check the toothed belt tension by pressing your finger on the belt in place "A" between belt pulleys 1 and 2. The deflection of the belt must be between 4 and 5 mm. If necessary, loosen the nut and bolt and press the tensioner against the toothed belt again.

9. Install the crankshaft sprocket, high pressure fuel pump drive gear and camshaft sprocket. Tighten the bolts to the specified tightening torques. At the same time, keep the shafts from turning.

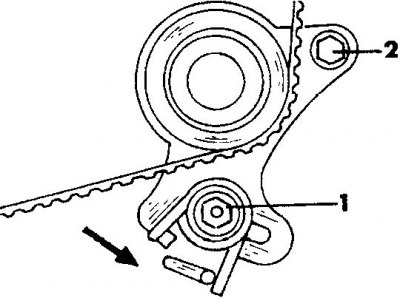

10. Install the toothed belt tensioner. Install the tension roller with spring and spacer and tighten the nut. Press the tension roller with a screwdriver in the direction of the arrow (see fig. Installing the toothed belt tensioner) and in this position tighten the bolt. Hand tighten the bolt.

11. Turn gear pulleys so that labels were established in the provisions specified in fig. Set the timing marks on the diesel engine, and fit the toothed belt without turning the toothed pulleys. Ensure the tension of the belt in the places indicated in fig. To tension the timing belt, and apply the belt in the following sequence: crankshaft sprocket, high pressure fuel pump drive gear, idler pulley and camshaft sprocket.

12. When applying a toothed belt to the high pressure fuel pump gear, it should be held, as it can easily turn. When reinstalling a removed toothed belt, it must be installed in its original position. Check up position of labels after imposing of a gear belt.

13. Loosen the bolt "1" (see fig. Installing the toothed belt tensioner) one or two turns and let the tensioner pull against the toothed belt, that is, in the direction of the arrow in the figure. Check the position of the marks again. Turn the crankshaft two teeth of the gear shaft and leave it in this position. At the same time, turn the crankshaft in the direction of the working rotation of the engine and in no case vice versa. In this position, tighten the bolt first "2", and then bolt "1" tightening torque 22–30 N·m.

14. Again unscrew the crankshaft in the opposite direction until the marks match and check the toothed belt tension between the camshaft sprocket and the high pressure fuel pump drive gear. When you press the belt with your finger, the deflection of the belt should be 4-5 mm. If necessary, re-adjust the toothed belt tension.

15. Install the flange. Note that the flange and pinion holes are offset, meaning the flange can only be installed in one position.

Insert and tighten the bolts.

16. While holding the high pressure fuel pump drive gear, tighten the nut to a torque of 80–90 Nm.

17. The rest of the work is done in reverse order. Tighten the crankshaft pulley bolt to 170–190 Nm. At the same time, keep the crankshaft from turning. If the engine is installed, shift into gear. Otherwise, block the flywheel crown.