Disassembly

1. Pistons can be removed after removal of retaining rings. Place the piston in hot water and knock out the finger by placing the piston on a secure gasket with a suitable rod. Remove the rings one by one.

2. When using another tool, do not break the rings.

Examination

1. Thoroughly clean and check all parts. If parts are damaged or worn, they must be replaced.

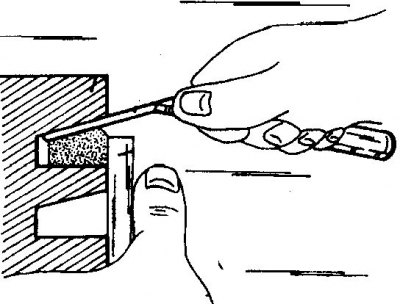

2. Measure the clearances in the piston grooves. To check the gap, it is required that the rings fit snugly in the grooves. To check, using the picture, place a flat bar against the piston to press the rings into the grooves, and then insert the feeler gauge at an angle to measure the gap. Before taking measurements, the grooves should be thoroughly cleaned.

If the piston ring height clearances are out of tolerance, replace the piston rings. In the worst case, you have to replace the pistons. Piston rings are available as well as oversized pistons.

3. Measure the butt gaps of the individual piston rings in the cylinder bores.

To do this, insert the rings one by one into the holes and push into the hole with the piston upside down until they are in the bottom of the hole. Measure the butt gap by inserting feeler gauges from the underside of the engine crankcase.

4. If the results differ from the values given in the tables of adjustments and sizes, the piston rings should be replaced.

5. Check the wear of the piston pins and their bores. The piston pin should move in the bore in the piston with an interference fit when the pin is moved after good lubrication. Also, the pin must move in the bushing hole on the diesel engine. The piston and pin must be at room temperature. In the connecting rod, the pin sits on a tight fit, which thus cannot be checked.

6. On the bottom of the piston there is an arrow pointing in the direction of the vehicle. Compliance with the installation position is very important, since the piston pin is inserted into the piston with an offset. On oversized pistons, the piston size is indicated on its crown (For example, "25", "50" etc.). The letters and numbers on the piston crown indicate the engine type. The piston is marked with letters "TS".

7. Check up absence of visible damages of rods. Be sure to replace damaged connecting rods. The connecting rods should be checked for misalignment or bending on a bench before reinstallation, especially when pistons are removed. Warped or bent connecting rods must be replaced.