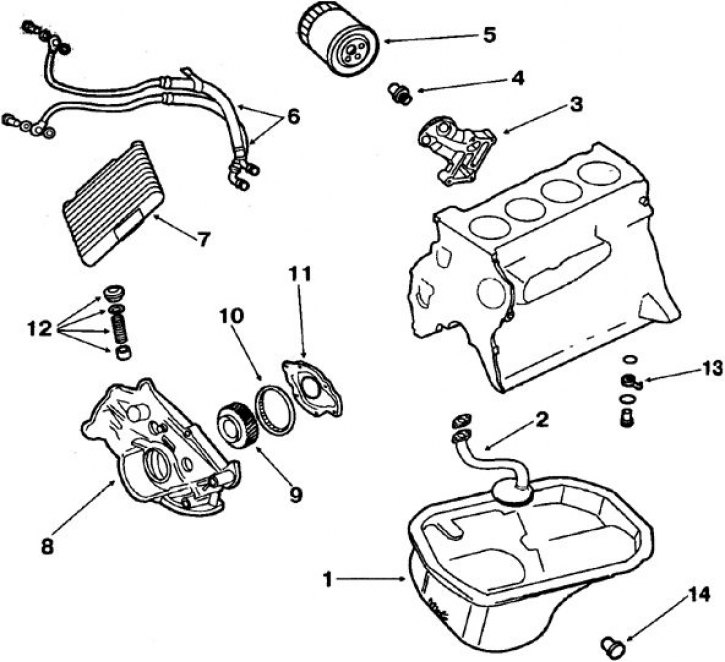

Parts of the lubrication system

1. Oil sump; 2. Oil receiver; 3. Oil filter bracket; 4. Oil filter bypass valve; 5. Oil filter; 6. Reinforced hose; 7. Oil cooler; 8. The bottom cover of the cylinder block; 9. Oil pump drive gear; 10. Oil pump driven gear; 11. Oil pump cover; 12. Pressure reducing valve; 13. Nozzles for cooling the piston bottom; 14. Oil drain plug

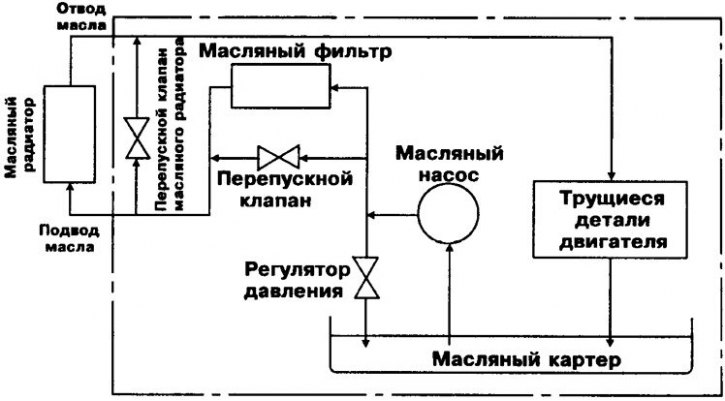

Scheme of the lubrication system of the 4D56T engine

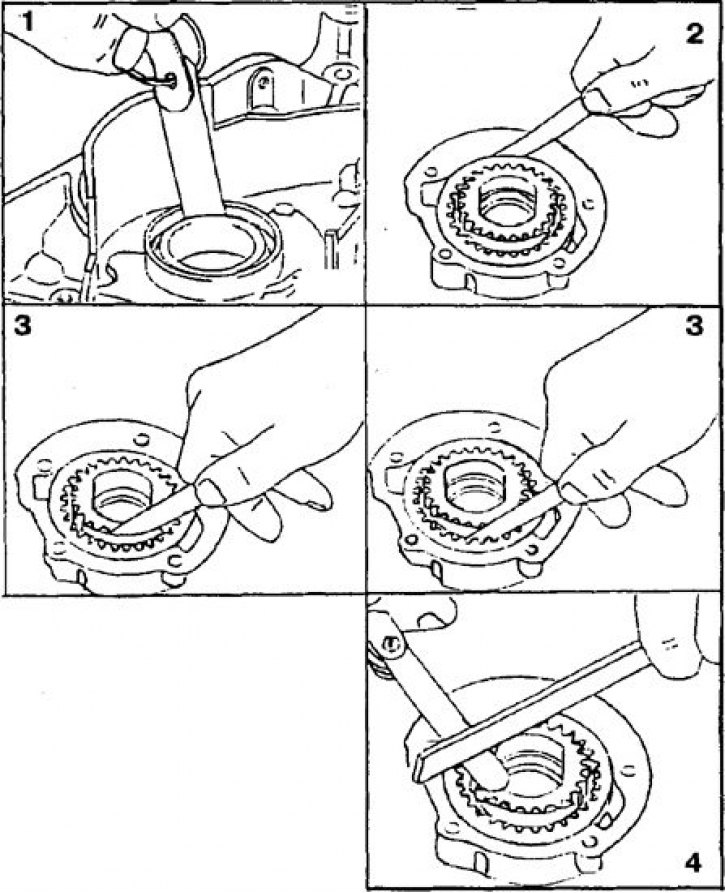

Checking clearances in the oil pump

1. Checking the clearance between the outer diameter of the drive gear and the pump housing bore

2. Checking the clearance between the outer diameter of the driven gear and the bore of the pump housing

3. Checking the gap between the gear teeth and the separating sickle

4. Checking the gap between the ends of the gears and the plane of the pump housing

The engine has a pressure lubrication system created by a gear pump driven directly from the crankshaft (see pic. Parts of the lubrication system).

In addition to the oil pump, the lubrication system includes an oil filter and an oil cooler, as well as nozzles installed at the base of each cylinder, through which oil is sprayed to cool the piston bottoms.

The oil pump is gear type with internal gearing.

Oil pressure at idle, kgf/cm2 – 2.

Activation pressure of the sensor of the control lamp of oil pressure, kgf / cm2 – 0,3.

Pressure of opening of valves of nozzles for cooling of the bottoms of pistons, kgf/cm2 – 2.

Attention! The 4D56T engines use a trochoidal gear pump instead of a gear oil pump for better performance.

Oil filter pressure reducing valve opening pressure, kgf/cm2 – 1,5.

Valve travel oil cooler thermostat, mm:

- at ambient temperature: 34.5;

- immersed in oil heated to 100°C: 40.

Oil cooling system opening temperature: 80°C.

The replaceable filter element is equipped with a built-in bypass valve.

When operating under normal conditions, the filter element must be replaced every 10,000 km of run, while operating under severe conditions - every 6,000 km of run.

Bypass valve opening pressure, kgf/cm2 – 5,5.

Filter element brand: Mitsubishi.

Attention! On 4D56T engines, a new oil filter with two stages of purification of the Mitsubishi brand is installed.

The plate-type oil cooler is installed in front of the radiator of the 4D56T engine cooling system.

Cooling capacity, kJ/h: 12.98.

The lubrication system includes a bypass line with a bypass valve that directs oil to the oil cooler (see fig. Scheme of the lubrication system of the 4D56T engine).

This ensures a continuous supply of oil to the rubbing parts of the engine in case of clogging and obstruction of the oil cooler. The opening of the bypass valve, mounted on the side of the engine, is determined only by the oil temperature. With the valve open, this reduces the time required to warm up the oil when starting a cold engine.

Removing

1. To remove the oil pump, remove the bottom cover of the cylinder block.

2. Remove the oil pump drive gear.

3. Remove the oil pump cover. Remove the driven and driving gears of the oil pump and apply alignment marks to the gears to put them in their original position during assembly.

4. To check the technical condition, make sure that the gear teeth do not show signs of wear and damage.

5. Using a set of probes and the data given in the subsection, check the gaps (see fig. Checking clearances in the oil pump):

- gap between the teeth of the drive gear and the separating sickle, mm: 0.22–0.35;

- gap between the teeth of the driven gear and the separating sickle, mm: 0.12–0.22;

- gap between the ends of the gears and the plane of the pump housing, mm: 0.04–0.10;

- gap between the outer diameter of the driven gear and the bore of the pump housing, mm: 0.12–0.22;

- gap between the outer diameter of the drive gear and the bore of the pump housing, mm: 0.03–0.09.

Assembly

The oil pump is assembled in the reverse order of disassembly, observing the marks made during disassembly on the gears.