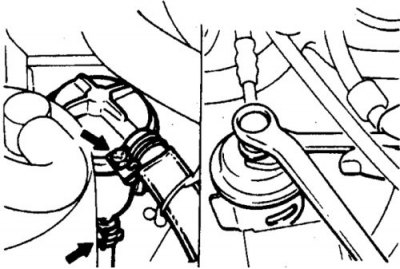

Fuel filter on carburetor and injection engines

On the left is the fuel filter on carbureted engines.

On the right is the fuel filter on injection engines.

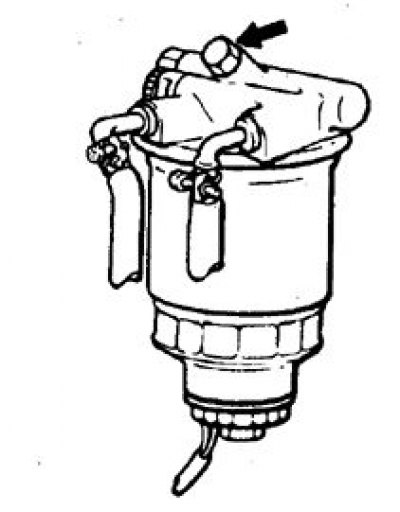

Fuel filter on 2.6L engines

The fuel filter is indicated by an arrow.

On carburetor engines, the filter is mounted on the frame channel in series with the fuel line and is attached to the hoses with clamps.

On injection engines, a high-pressure filter is used, which is also mounted on the frame channel and is connected to the line through union fittings.

Decompress the fuel system before removing the filter (see subsection 8.2.1). If the filter is very dirty, remove and rinse the tank. To access the filters, it is recommended to raise the vehicle.

Carburetor engines

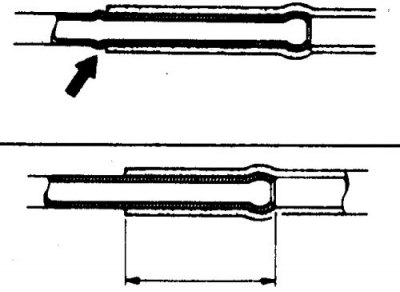

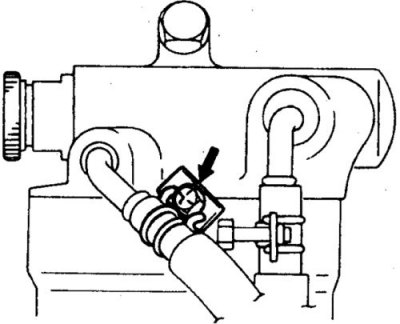

Hose Connection Diagram

The hose must go beyond the nozzle (indicated by an arrow) not less than 25 mm.

1. Disconnect the battery from the ground.

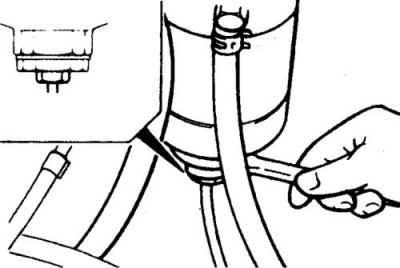

2. Loosen the clamps.

3. Disconnect the hoses and remove the filter from the bracket.

4. Check up a condition of hoses, if necessary replace.

5. Installation is carried out in the reverse order. Attach the hoses in the correct order.

Injection engines

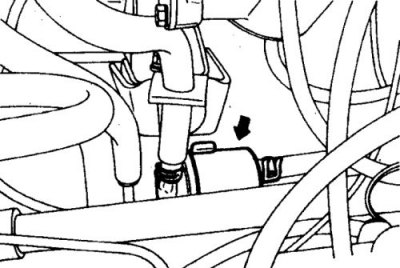

Attention! On some vehicles, there is a fuel pump hatch, to access which you need to remove the carpet in the cargo compartment and the floor covering. Remove the hatch, disconnect the connector and start the engine, exhaust the remaining fuel. After these measures, the pressure in the fuel system will decrease.

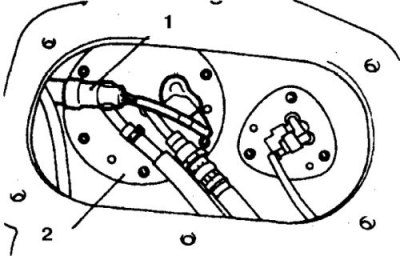

Fuel pump hatch

Replacement

1. Decompress (see subsection 8.2.1).

2. Disconnect the battery from the ground.

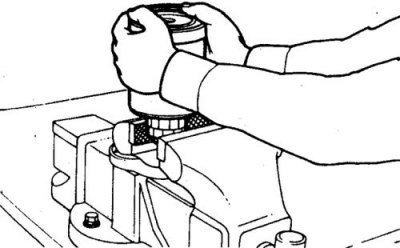

3. Remove the air filter.

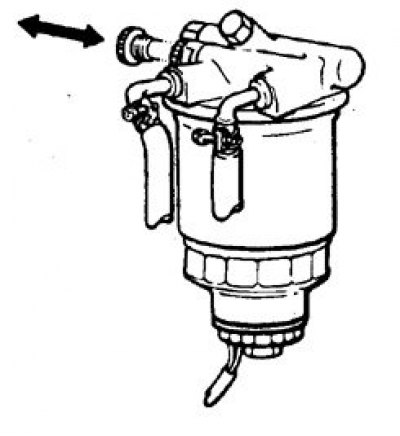

4. Turn away bolts of unions and disconnect hoses.

5. Turn away a bolt of fastening and remove the filter.

6. Installation is carried out in the reverse order. Tighten the bolts of the outlet and inlet hose fittings with a torque of 24–34 and 34 Nm. respectively.

Diesel

A replaceable fuel filter element is installed in a tank, which is mounted in the engine compartment.

Fuel pump wires

1. connector

2. Fuel pump

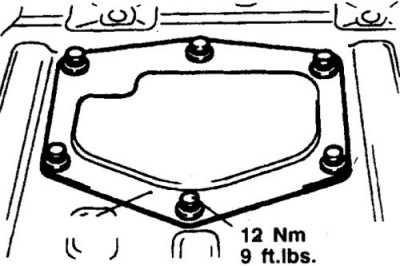

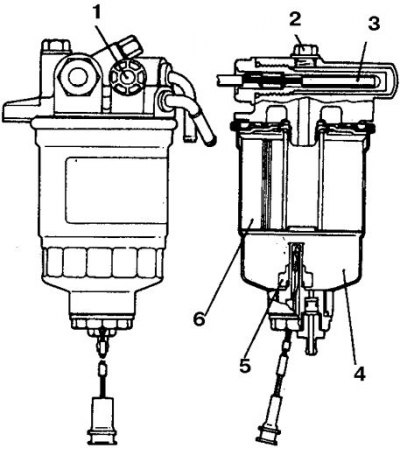

Diesel fuel filter

1. Manual fuel pump; 2. Fuel temperature sensor; 3. Heater; 4. Sump (dehumidifier); 5. Water level sensor; 6. Filter element

Correct clamp position

1. Designate and disconnect from a tank with the filter connectors.

2. Lay a rag, carefully disconnect the hoses.

3. Turn away bolts of fastening and remove a filter tank.

4. Remove the bracket and shield from the tank.

5. Unscrew the filter from the reservoir by hand.

Unscrew the water level sensor and plug from the filter element.

6. The filter element is recommended to be replaced. You can limit it to a thorough washing in kerosene.

7. Installation is carried out in the reverse order. Tighten the water level sensor and plug with a torque of 9 and 4 Nm. respectively. Remove air from the system in the following order:

- release the plug to remove air;

- unscrew the plug of the lever of the manual pumping pump and pull out the lever;

- pump up fuel until air bubbles disappear, tighten the plug;

- continue pumping fuel until the lever stroke becomes stiff;

- push and fold the lever.

Removing moisture from the diesel fuel filter

At fire of a control lamp of level of water in a sump from the fuel filter it is necessary to remove moisture.

|  |

1. Remove the drain plug at the bottom of the filter.

2. Unscrew the cap on the manual priming pump lever and pull out the lever.

3. Continue adding fuel until no more water comes out.

4. Slide in and fold the lever.