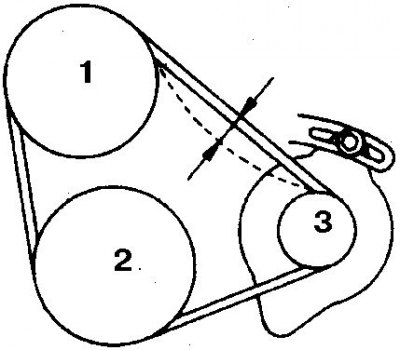

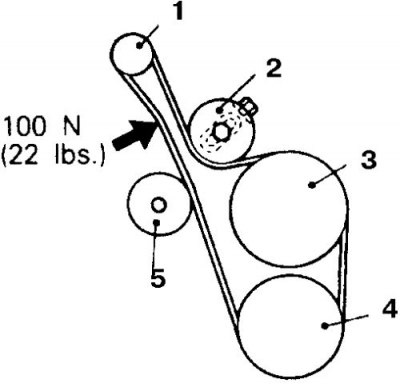

To check the belt tension, press the belt halfway between the pulleys and check the depth of the belt deflection. Measure the amount of belt deflection, which should be 6–10 mm at a force of 9 kgf.

Alternator Belt Tension Adjustment

1. Coolant pump pulley

2. Alternator pulley

3. Crankshaft pulley

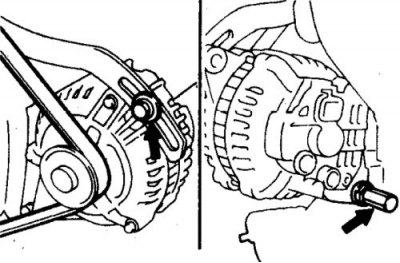

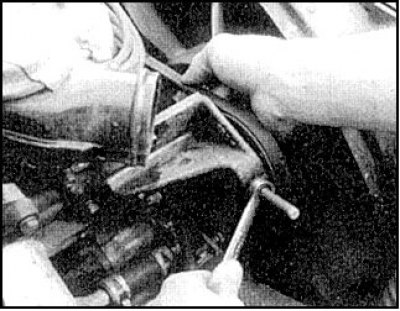

Alternator axle bolt and unit mounting bolt in the slot of the bracket

Left - alternator axle bolt

On the right - the bolt of the unit in the slot of the bracket

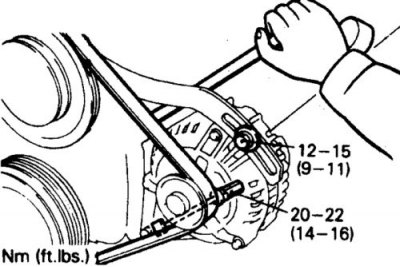

Alternator Belt Tension Adjustment

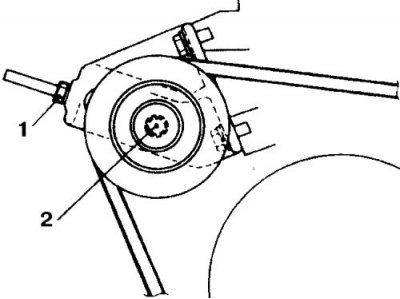

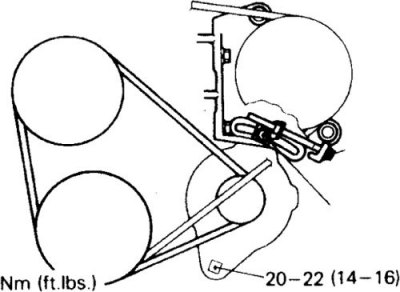

Scheme for adjusting the belt tension by moving the tensioner roller

1. Adjusting nut

2. Roller axle locknut

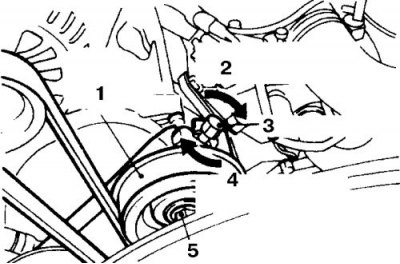

Adjusting the belt tension by turning the adjusting washer

Scheme for adjusting the tension of the alternator belt by moving the rotation of the bolt

Bolt for adjusting belt tension on most vehicles

1. Tensioner; 2. Tension; 3. Bolt; 4. Weakening; 5. Nut

Drive belt adjustment points

1. Alternator pulley; 2, 5. Tensioner; 3. Alternator pulley; 4. Crankshaft pulley

Adjustment

1. If it is necessary to adjust the tension of the alternator belt or power steering pump, then loosen the unit axle bolt.

2. Then the unit mounting bolt in the slot of the bracket.

3. Move the unit by pulling (or letting go) belt and tighten the bolts in reverse order.

4. On later models, the belt tension is adjusted by moving the tensioner roller by rotating the guide stud nut with the roller axle lock nut released.

Removal and installation

To remove the belt, follow the same steps as when adjusting, only move the pulley (or aggregate) so that the belt can be removed and put on a new one. Do not put on the belt with excessive force. First make sure that the belt is fully consistent with the one removed.

Toothed belt

Check the integrity of the belt, the absence of traces of oil and fluid. The belt is changed every 96,000 km. See subsection for removal procedure 3.4.29.1, subsection 3.4.29.2, subsection 3.4.29.3.