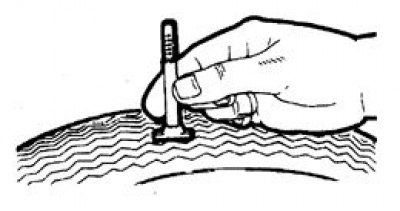

Tread Depth Check

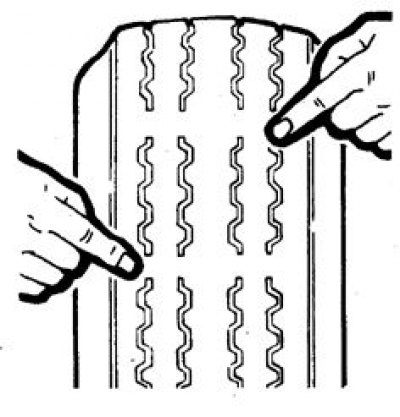

Tire wear and damage check

Tire care comes down to checking the tread depth, tire pressure (tested on cold tires), identifying traces of abnormal wear and damage, by which you can determine the condition of the parts of the front suspension and steering.

Regularly remove stones or sharp objects stuck in the tread. Periodically remove the wheels and clean the outer and inner surfaces of the disc from dirt.

If in doubt about the consequences of any damage found, consult a tire repair shop. Rearrange the wheels at regular intervals. When installing a new tire on a rim, keep the following in mind.

The width of the tire tread must differ from the distance between the inner beads of the tire by no more than 25 mm. On radial tires, the width between the inner beads must not exceed 80% of the tire width.

The height of the tire in the installed state significantly affects the accuracy of the speedometer readings, the dynamics of acceleration and the clearance of the car. The necessary corrections are specified by the tire manufacturer. Speedometer gearboxes with corrected gear ratio are supplied as spare parts.

When installing new tires, there should be no abnormal body tilt when driving on bumpy roads or when cornering.

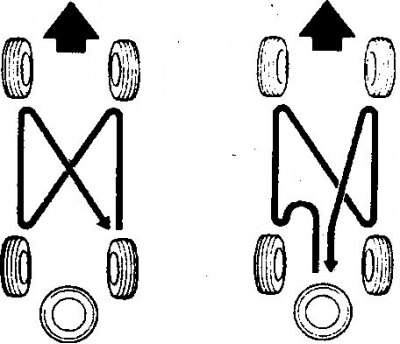

Wheel swap

Wheel swap diagram

The wheels are rearranged in order to improve the uniformity of tire wear after 12,000 km.

When removing winter studded tires, mark the position of the removed wheel and the direction of the studs. It is not allowed to change wheels, the tires of which are designed for different loads and are installed on the front and rear axles separately.

The manufacturer recommends installing radial tires in a single set (5 wheels). It is allowed in extreme cases to install radial tires of the same design on the rear axle.