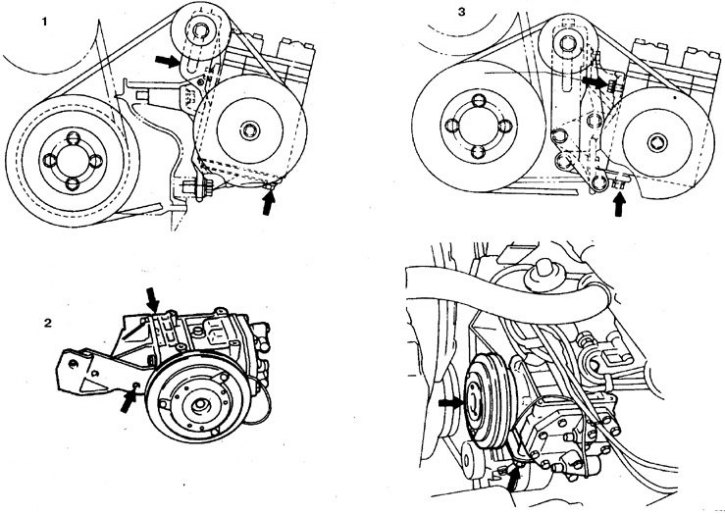

Compressor mounting on G63 engines (1), G55 (2), D55 (3)

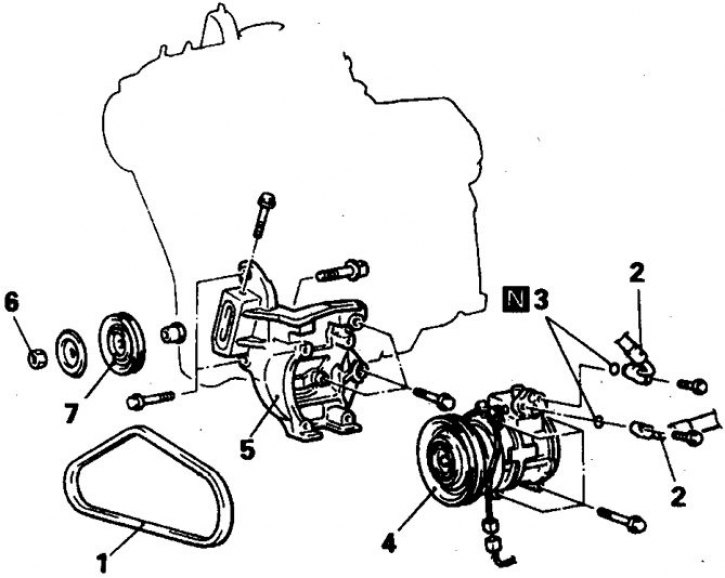

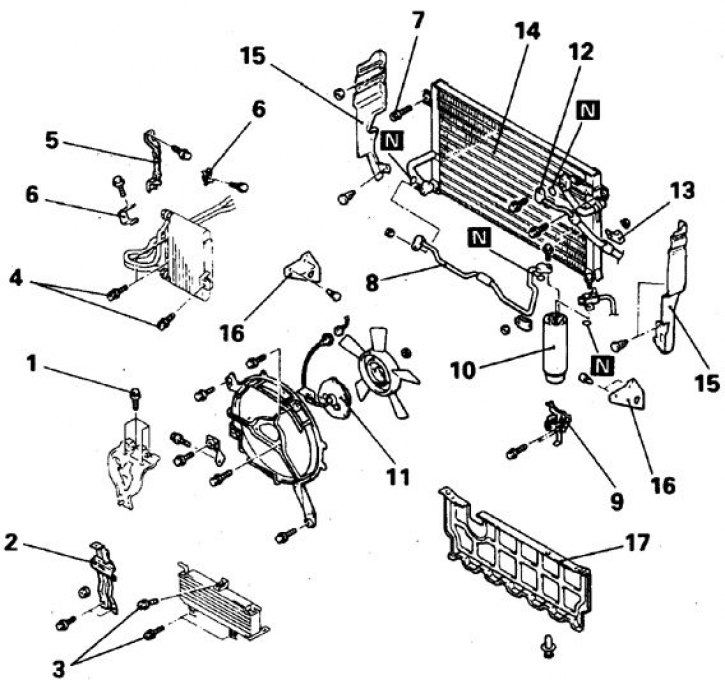

Air conditioning compressor (6-cylinder engines)

1. Belt; 2. Hose fittings; 3. O-rings; 4. Compressor; 5. Bracket; 6. Pulley nut; 7. Tensioner roller

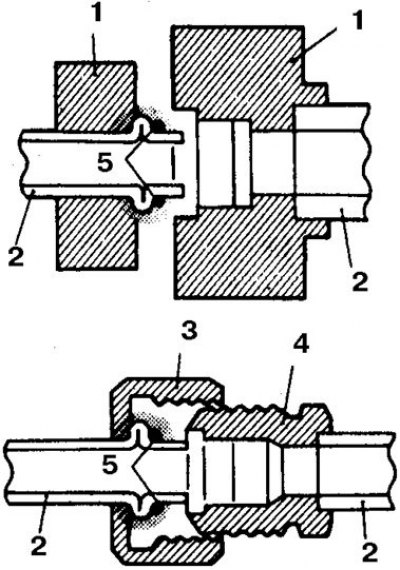

Types of connections of branch pipes on the condenser

1. Flange; 2. Tube; 3. Nut; 4. Fitting; 5. Ring

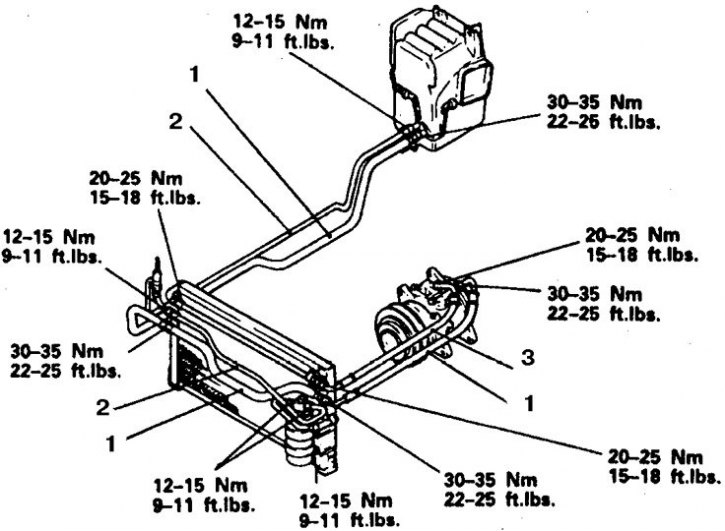

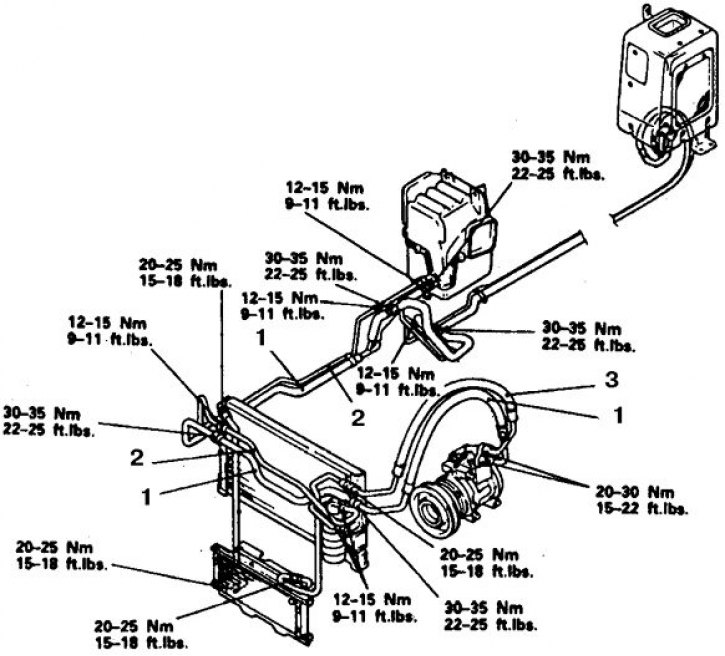

1-stage air conditioning line for vehicles with 2.6 and 3.0 l engines (12-valve)

1. Suction line; 2. Line with liquid refrigerant; 3. Discharge line

2-stage air conditioning line for vehicles with 2.6 and 12-valve 3.0 l engines

1. Suction line; 2. Line with liquid refrigerant; 3. Discharge line

2-stage air conditioning line for vehicles with 3.5 and 24-valve 3.0 l engines

1. Hood lock bracket; 2. Rack; 3. Transmission fluid cooler bolt; 4. Oil cooler bolt; 5. Oil cooler bracket; 6, 13. Bracket; 7. Capacitor mounting bolt; 8. High pressure tube; 9. Receiver/dryer bracket; 10. Receiver; 11. Fan; 12. High pressure hose; 14. Capacitor; 15, 16, 17. Seal

Removal and installation

1. Depressurize the refrigerant line in a car service.

2. Disconnect the battery from the ground.

4-cylinder engines

3. Remove the ignition distributor cap (2.0 l) or coil (2.6 l) and take it aside.

4. Remove the drive belt.

5. Disconnect the wires from the compressor.

6. Disconnect the hoses from the compressor, plug the holes immediately.

7. Turn away the top bolts of the compressor, having paid attention to their arrangement.

8. While holding the compressor, unscrew the bottom bolt and remove the compressor.

9. Installation is carried out in the reverse order.

10. Bolts of the compressor wrap in the order of their previous installation.

11. Replace hose o-rings.

6-cylinder engines

12. Remove a radiator casing.

13. Remove the drive belt.

14. Disconnect the wires from the compressor.

15. Disconnect the wires from the compressor.

16. Disconnect the hoses from the compressor, plug the holes immediately.

17. Turn away the top bolts of the compressor, having paid attention to their arrangement.

18. Holding the compressor, turn away the lower bolt and remove the compressor.

19. Installation is carried out in the reverse order.

20. Bolts of the compressor wrap in the order of their previous installation.

21. Replace hose o-rings.