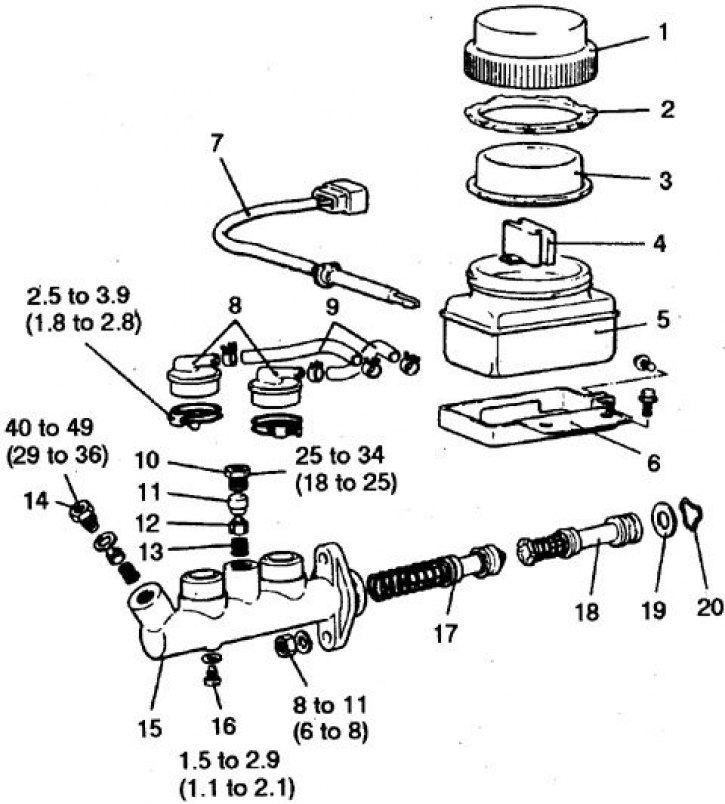

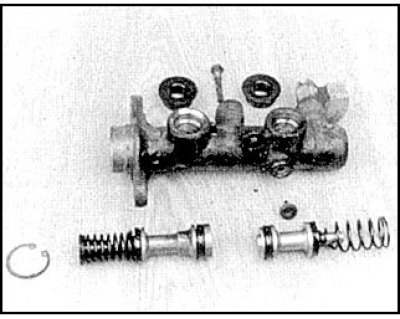

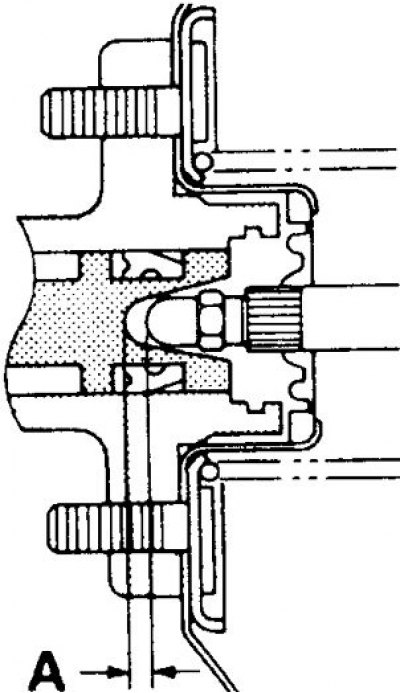

Brake Master Cylinder Parts (1983-86)

1. Tank stopper; 2. Washer; 3. Aperture; 4. float; 5. Tank; 6. Holder; 7. Sensor; 8. Fitting; 9. Hose; 10. Plug; 11. Saddle; 12. Valve; 13. Spring; 14. Valve body; 15. Cylinder; 16. Restrictive bolt; 17, 18. Pistons with springs; 19. Retaining ring; 20. Spring

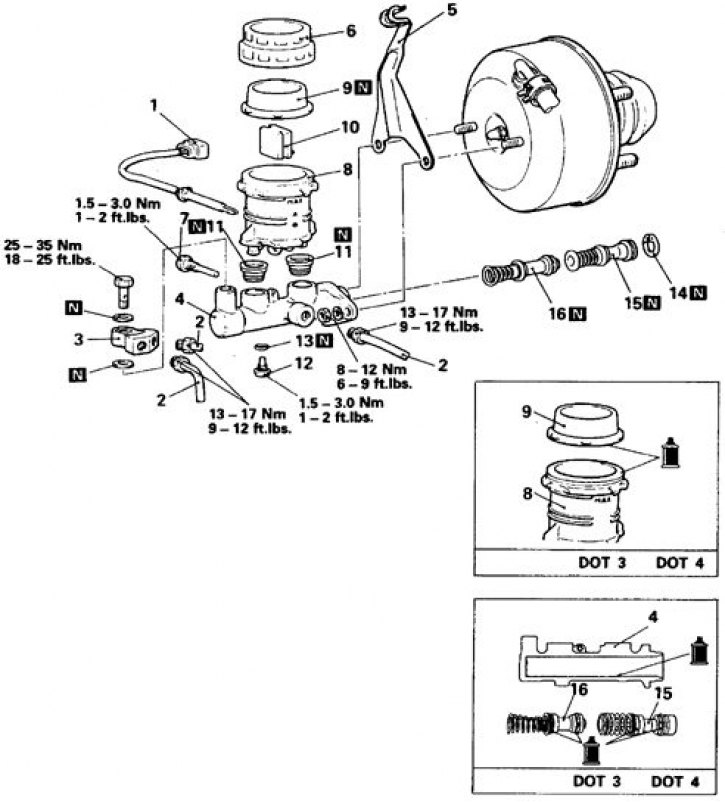

Brake Master Cylinder Parts (1987-98)

N - must be replaced during disassembly

1. Liquid level sensor connector; 2. Pipe fittings; 3. connector; 4. Master cylinder; 5. Bracket

Amplifier rod protrusion adjustment:; 6. Tank stopper; 7. Bolt; 8. Tank; 9. Diaphragm; 10. Float; 11. Seal; 12. Restrictive bolt; 13. Gasket; 14. Retaining ring; 15, 16. Pistons with springs

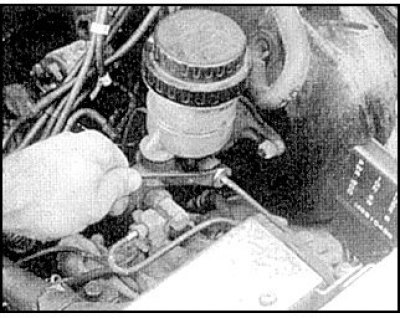

Removal and installation

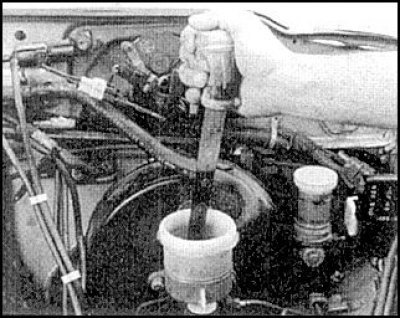

1. Remove fluid from reservoir.

2. Disconnect the wire from the liquid level indicator.

3. Disconnect from the cylinder of the union of tubes of a hydrodrive of brakes.

4. Turn away nuts and remove the cylinder.

5. Installation is carried out in the reverse order.

6. Tighten all connections to the required torque.

7. Remove air from the hydraulic actuator.

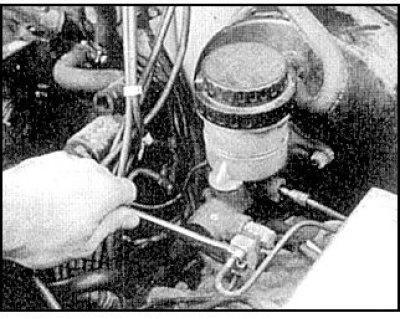

Disassembly and assembly

1. Remove fluid from reservoir.

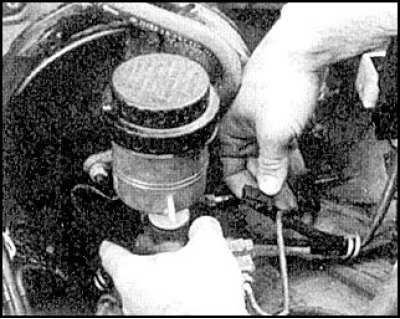

2. Disconnect the fluid level sensor connector.

3. Disconnect the brake side tube.

4. Disconnect the front brake pipe.

5. Turn away nuts.

6. Remove the cylinder.

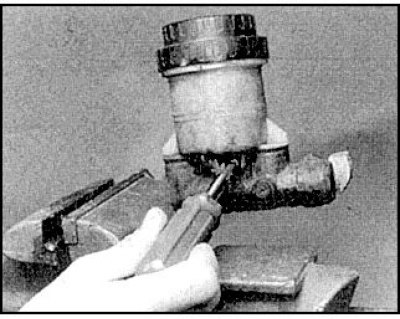

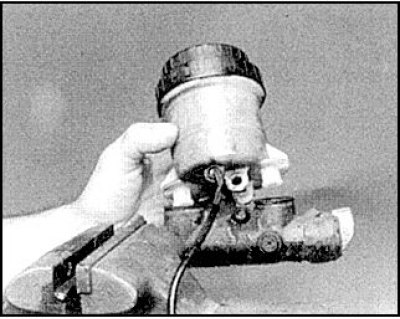

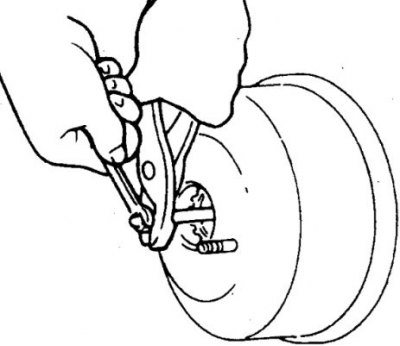

7. Clamp the cylinder in a vice on the flange.

8. Turn away a bolt and remove a tank.

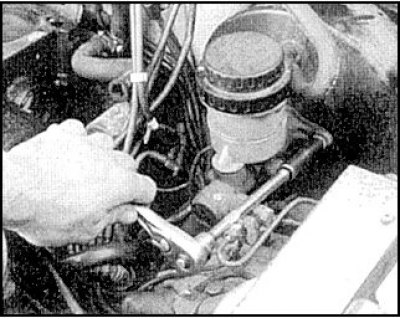

9. Turn away cap nuts and get linings.

10. Turn out a restrictive bolt of the piston.

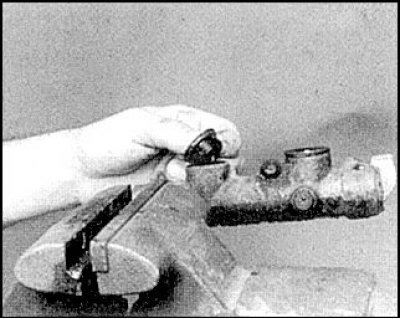

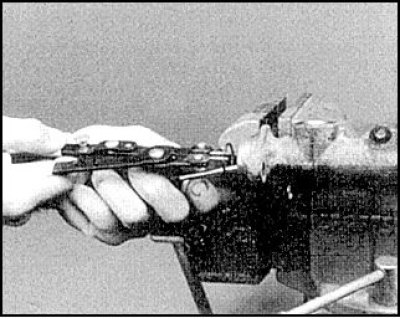

11. Remove retaining ring.

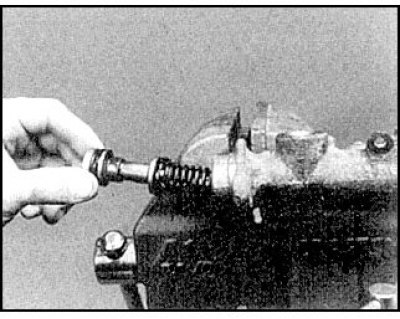

12. Get the first piston (do not bend the piston).

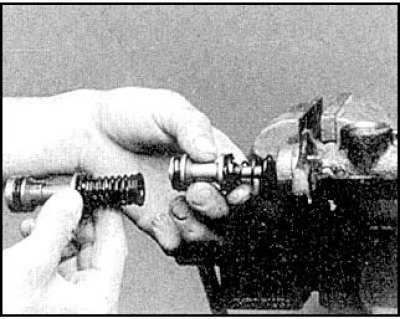

13. Get the second piston.

14. When disassembling, pay attention to the order of the parts.

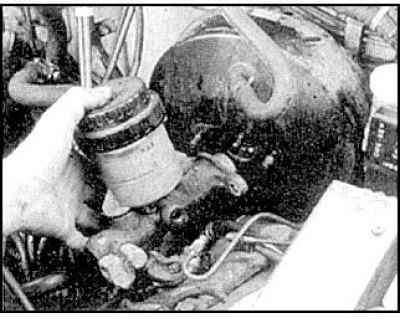

15. Assembly is carried out in the reverse order, taking into account the following.

16. Check the cylinder diameter in 6 places in mutually perpendicular directions. If the variation in measurements exceeds 0.025 mm, then replace the cylinder assembly.

17. Check up a backlash between the piston and the cylinder which should be no more than 0,15 mm, otherwise the cylinder in gathering replace.

18. Replace all seals.

19. Tighten all connections on the cylinder to the correct torque.

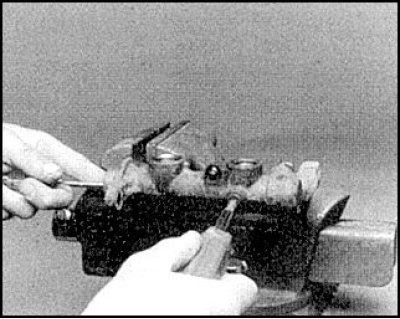

20. Before installing the cylinder, determine clearance A using the formula A = B - C - D.

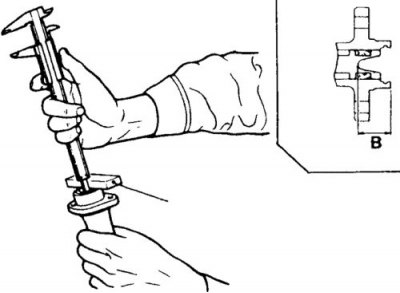

21. To determine A, measure distance B through a plate with an accurately measured thickness.

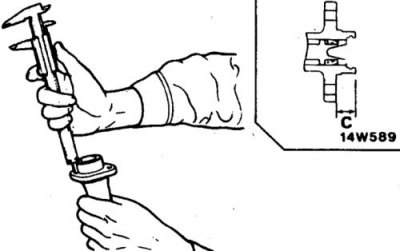

22. Measure distance C.

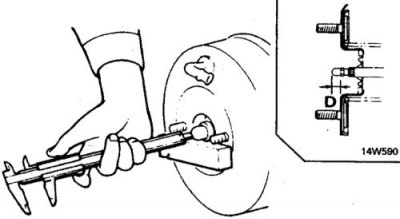

23. Then measure the distance D through the plate with the exact thickness measured.

24. Calculate distance A. The gap should be 0.1–0.15 mm.

25. If necessary, adjust clearance A by rotating the brake booster rod and measuring distance D.

26. When finished, bleed the brakes.