Removing the retaining ring

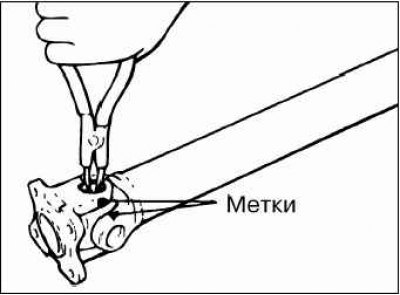

Before removing the retaining ring, mark the position of the universal joint forks.

Removing the universal joint bearing

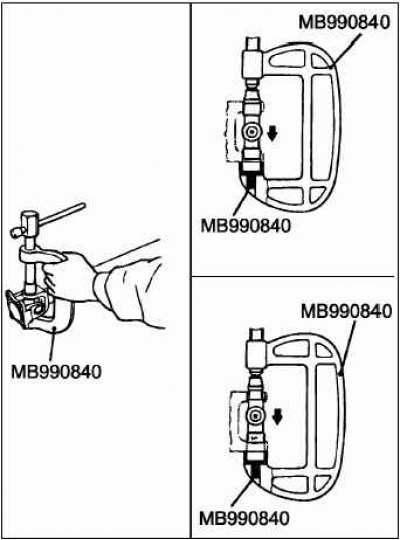

Using the special tool, press out the yoke bearing on one side of the universal joint while pushing the bearing on the other side of the yoke.

Move the special tool to the other side and press out the second bearing by pressing on the cross.

Attention! It is not allowed to knock out the bearings when removing, as this can lead to imbalance of the cardan shaft.

Removing the fork of the intermediate support

Before removing the intermediate shaft support yoke, mark the relative position of the yoke and the intermediate propeller shaft.

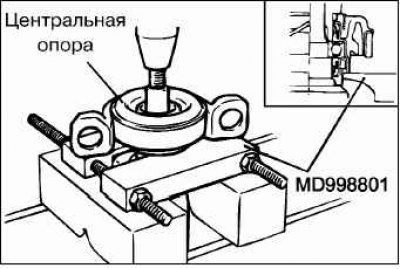

Removing the intermediate support assembly

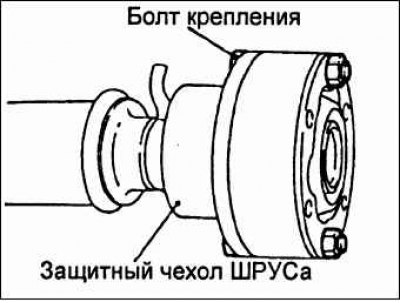

Mark the relative position of the intermediate driveshaft, CV joint assembly and flange, then remove the bolt.

Using a puller, remove the intermediate support assembly from the intermediate propeller shaft.

Attention! The use of excessive amounts of grease will result in assembly difficulties and improper selection of circlips

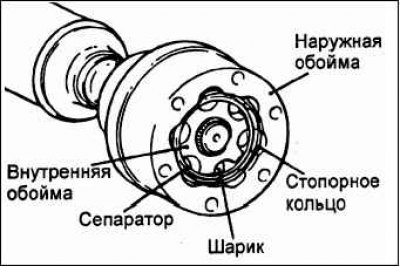

Removing the CV joint assembly

Remove the protective cover from the CV joint assembly.

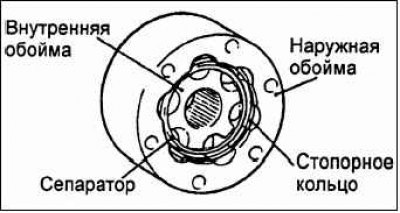

Mark the relative position of the outer race, cage, and inner race of the CV joint, then remove the circlip, outer race, and balls.

Note. Remember or write down the location of the balls so as not to confuse their original location during installation.

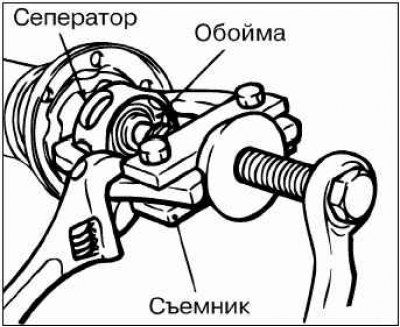

Using a universal puller, remove the inner race and CV joint separator from the intermediate driveshaft.

Remove old grease and clean outer and inner races, separator and CV joint balls.

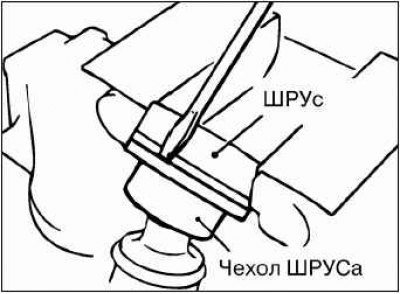

Removing the protective cover of the CV joint

If it is intended to re-install the CV joint protective boot, then wrap the splines of the rear driveshaft with insulating tape before removing it.

Installing a protective cover SHRUS

Establish a collar of a protective cover of SHRUS.

Wrap the splines of the intermediate cardan shaft with insulating tape, then install the CV joint protective cover.

Installation of CV joint assembly

Apply a light coat of special grease to the ball grooves on the outer and inner races of the CV joint.

Install the outer race, cage, balls, and inner race by aligning the relative position marks.

Install retaining ring.

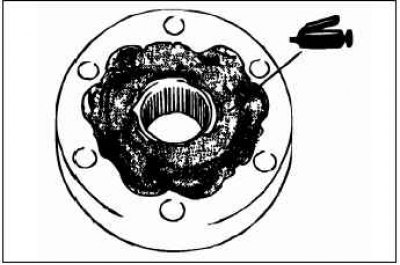

Apply special grease to the CV joint assembly.

Quantity: 90-100 g.

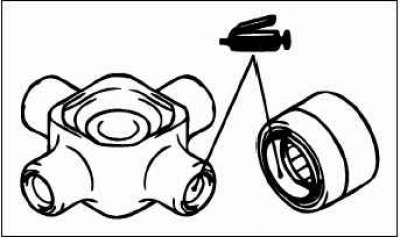

Apply a little special glue at three points on the surface of the ball grooves (shown in the figure by arrows), located at the same distance from each other along the circumference of the CV joint, in which there are grooves for the rubber seal and then install the rubber seal on the CV joint.

Adhesive: 3M Stud Locking #4170 or equivalent.

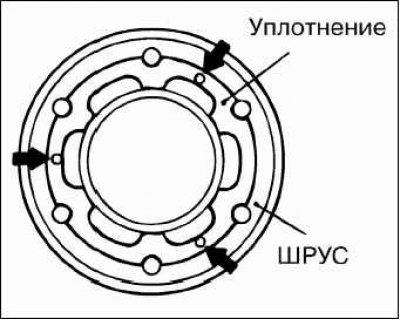

Position the CV joint so that the side with the grooves on which the rubber seal of the CV joint was previously installed is directed towards the protective boot of the CV joint.

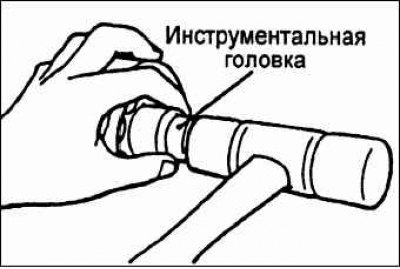

Align the marks on the CV joint assembly and the intermediate drive shaft, then use a tool head to install the CV joint assembly on the intermediate drive shaft.

Align the bolt holes on the protective cover of the CV joint and the CV joint assembly with the fastening bolts, and install the protective cover on the CV joint.

Install the rubber seal on the CV joint from the flange side.

Installation of a collar of a protective cover of SHRUS

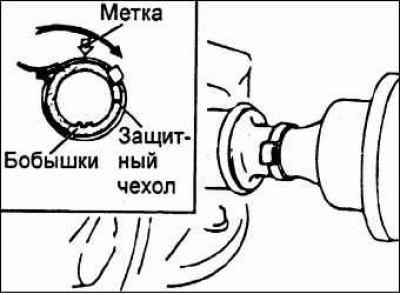

Position the lock of the protective boot yoke so that it is on the opposite side of the protective boot from the ventilation bosses of the boot (indicated by the arrow in the figure). Make sure there is no grease around the boot bosses, as grease will obstruct ventilation through the channels.

Installing the intermediate support assembly, flange and self-locking nut

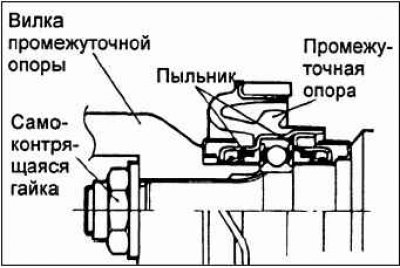

Install the intermediate support assembly to the intermediate propeller shaft as shown in the illustration.

Align the previously made alignment marks on the relative position on the flange and the intermediate propeller shaft.

Press the flange and intermediate support assembly firmly while tightening the self-locking nut.

Installing the intermediate support assembly, intermediate support fork and self-locking nut

Install the intermediate support assembly to the intermediate propeller shaft as shown in the illustration.

Align the marks with respect to the position of the intermediate support yoke and the intermediate propeller shaft.

Press the yoke and intermediate support assembly firmly while tightening the self-locking nut.

Cross and bearing installation

Apply grease to the running surfaces of the bearing crosses.

Attention! Using too much grease will result in assembly difficulties and misalignment of circlips.

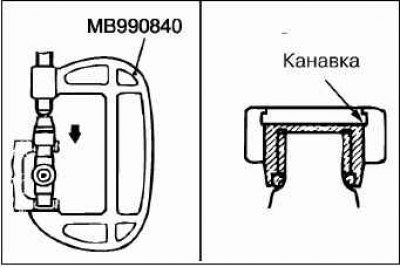

Using the special tool, press the spider bearing into the yoke until the circlip groove is fully visible. Attention: be careful when pressing the bearings of the cross, as the misalignment of the bearing during pressing will damage it to the cross.

Using the special tool, press the bearing on the opposite side of the spider into the yoke.

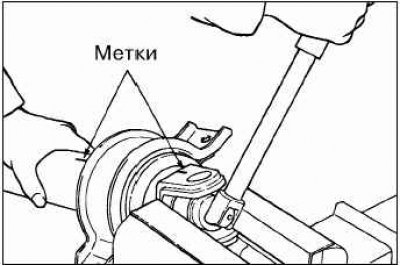

Align the relative position marks of the yoke and the propeller shaft, install the second pair of universal joint bearings according to the procedures in subparagraphs «A» And «b».

Retaining ring installation

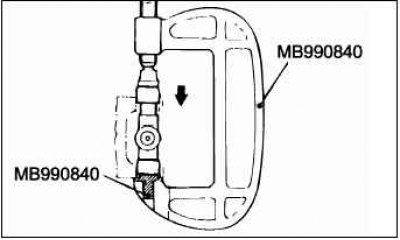

Install the retaining ring on one side of the universal joint cross.

Install the puller on the side opposite to that where the retaining ring is installed and press the bearing until it touches the retaining ring.

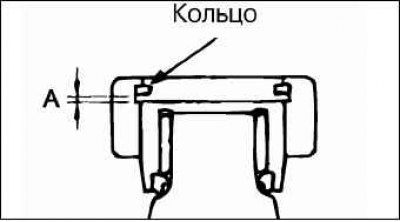

Install the retaining ring on the opposite side. Measure the axial clearance of the universal joint bearing (between circlip and bearing) with a flat feeler gauge.

Nominal clearance: 0.02-0.06 mm.

Attention! Retaining rings on both sides must be the same thickness.

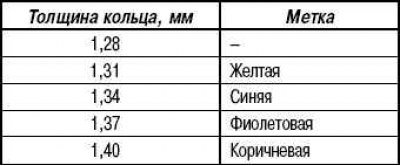

If the axial clearance exceeds the nominal value, then adjust it by selecting a retaining ring of suitable thickness.