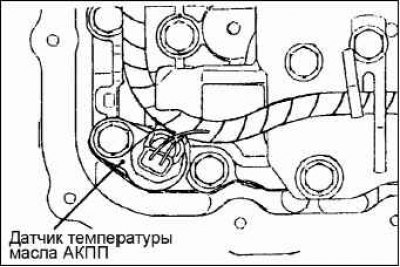

Checking the automatic transmission oil temperature sensor

Remove the automatic transmission oil temperature sensor.

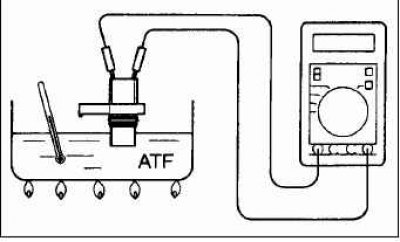

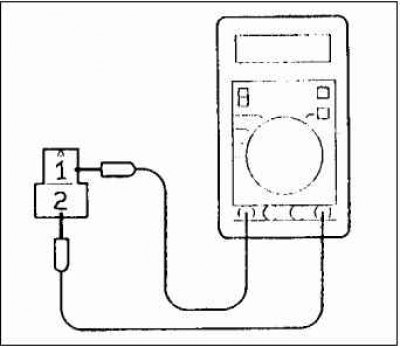

Measure the resistance between pins #1 and #2 of the automatic transmission oil temperature sensor connector.

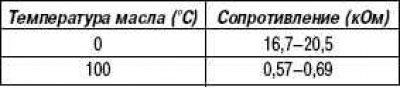

Rated value

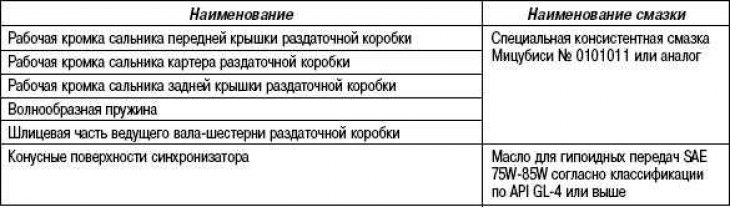

Lubricant used. Transfer case

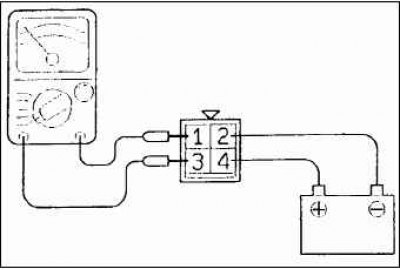

Checking the automatic transmission control relay

|  |

Remove the automatic transmission control relay.

Using jumper wires, connect output 2 of the control relay to the negative terminal (–) battery, and pin 4 with a positive terminal (+).

Check the condition of the circuit between terminals 1 and 3 of the automatic transmission control relay.

If there is a malfunction, replace the automatic transmission control relay.

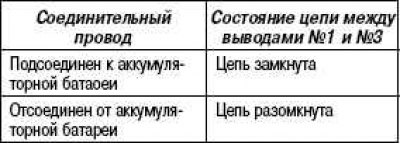

Checking the solenoid valves

Remove the control valve block cover. Disconnect the connectors for each solenoid valve.

Measure the resistance value between terminals 1 and 2 of each solenoid valve connector.

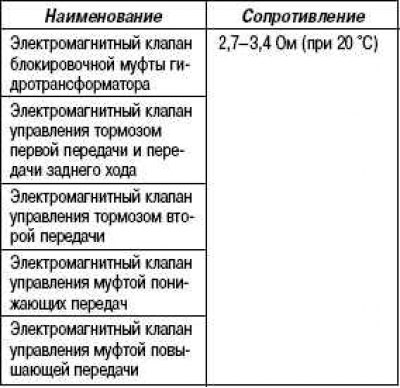

Rated values

If the resistance does not match the required value, then replace the solenoid valve.

Fully braked test (STALL TEST)

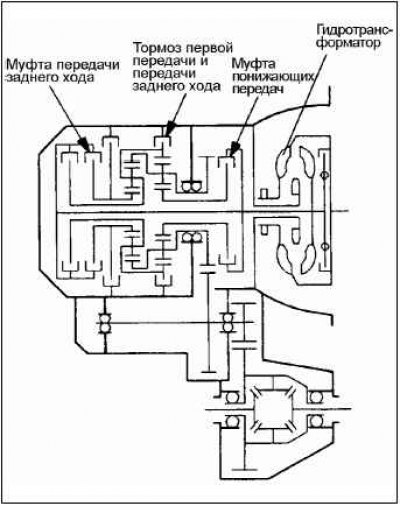

The purpose of this check is to measure the maximum engine speed on the ranges «D» And «R» with the output shaft of the automatic transmission completely stopped. By the value of this speed, one can judge the performance of the torque converter, freewheel, and also determine the presence of slip in some frictional controls of the automatic transmission.

Attention! During this check, people should not be in front and behind the car.

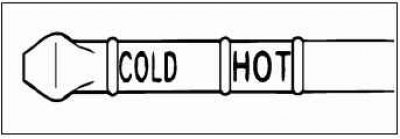

Check the automatic transmission oil level and temperature, as well as the engine coolant temperature.

- Oil level: mark «NOT» on the dipstick.

- Oil temperature: 80–100°C.

- Engine coolant temperature: 80–100°С.

Place chocks under the rear wheels.

Apply the parking brake fully and fully depress the brake pedal.

Start the engine.

Set the automatic transmission selector lever to the position «D», fully depress the accelerator pedal and determine the engine speed at this moment.

Attention! Do not hold the accelerator pedal fully depressed for more than eight seconds.

If this test is carried out two or more times in a row, then after each test it is necessary to move the automatic transmission selector lever to the position «N» and allow the oil in the automatic transmission to cool down to operating temperature when the engine is running at a frequency of 1000 min-1, after which the next test can be carried out.

Rated value of the engine speed during the Stall Test: 2100–2600 min-1.

Set the automatic transmission selector lever to the position «R», fully depress the accelerator pedal and determine the engine speed at this moment.

Rated value of the engine speed during the Stall Test: 2100–2600 min-1.

Analysis of test results on a fully braked vehicle

Engine speed during the Stall Test on the ranges «D» And «R» more than the nominal value:

low pressure in the control system. 1st gear brake and reverse gear slip.

The engine speed during the Stall Test is greater than the nominal value only on the range «D»:

slippage of the underdrive clutch.

The engine speed during the Stall Test is greater than the nominal value only on the range «R»: Reverse clutch slip.

Engine speed during the Stall Test on the ranges «D» And «R» less than the minimum nominal value: the torque converter is faulty, the engine is faulty.

Main line pressure regulation

Drain the oil from the automatic transmission and remove the control valve block cover.

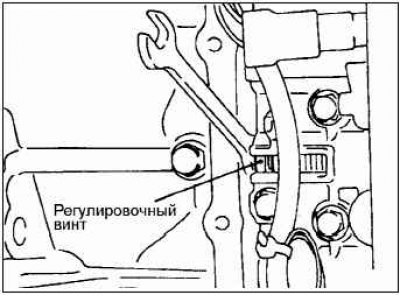

The pressure in the reduction gear booster is adjusted using the adjustment screw shown in the figure.

Turning the adjusting screw to the left increases the pressure.

Note. The pressure in the underdrive clutch booster should be in the middle of the rated range.

Nominal range: 1010-1050 kPa.

One turn of the adjusting screw changes the pressure value by 35 kPa.

Reinstall the control valve block cover, and fill the gearbox with oil.

Carry out a pressure test.

If necessary, readjust the pressure in the main line.

Checking the operation of the automatic transmission selector lever

Check the ease and smoothness of movement of the automatic transmission selector lever and its fixation in each position. Check the indication of the selector lever position indicator, which should match the position of the selector lever itself.

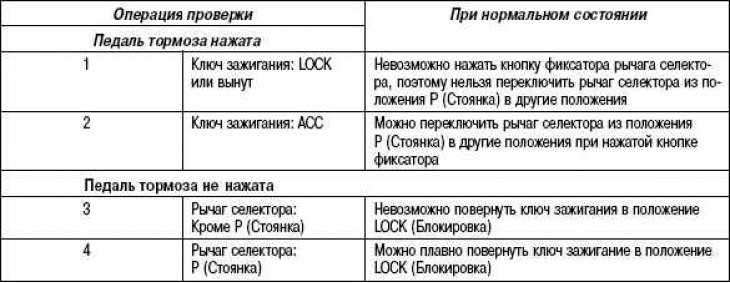

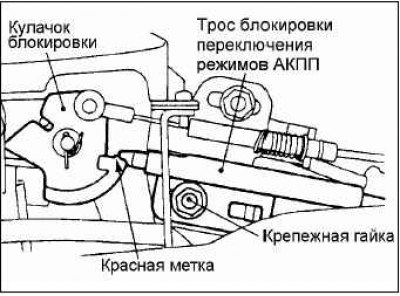

Check the operation of the mechanism for blocking the movement of the automatic transmission selector lever (see picture).

Start the engine and check the operation of the gearbox control mechanism (when moving the lever from the position «N» V «D» the car should move forward, and when you move the lever to the position «R» the car must move backwards).

If malfunctions are found in the gearbox control mechanism, adjust the cable of the control mechanism connecting the automatic transmission selector lever to the control valve block. Check for excessive wear on parts of the automatic transmission control mechanism.

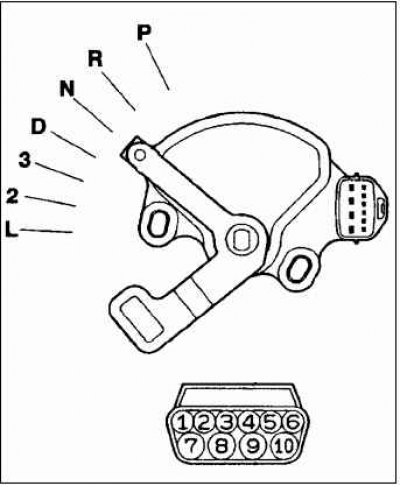

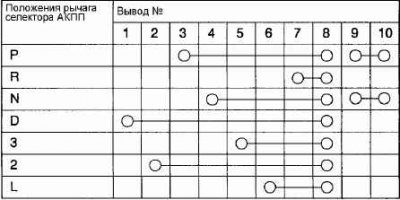

Starter Interlock Switch Test

|  |

Checking the ignition lock mechanism

Control Cable and Starter Interlock Switch Adjustment

Set the automatic transmission selector lever to the position «N».

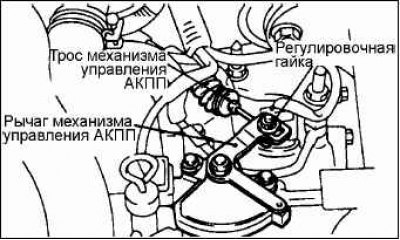

Loosen the adjusting nut securing the cable to the control lever so that the cable and lever are released.

Set the control lever to the position «N».

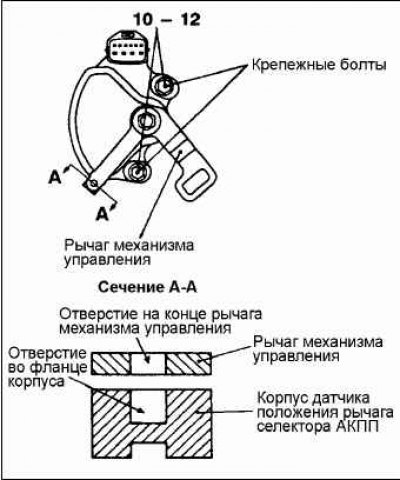

Loosen the range select lever position sensor mounting bolts and rotate it so that the hole in the sensor housing flange aligns with the hole in the end of the control lever (section A-A).

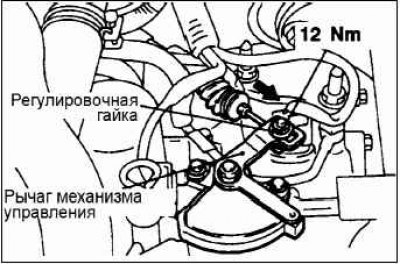

While holding the sensor in this position, tighten the fixing bolts to the specified torque.

Gently pull the cable connecting the selector lever to the control valve block in the direction of the arrow, and then tighten the adjusting nut.

Make sure the selector lever is in the position «N».

Check the correspondence of the included gears to the position of the automatic transmission selector lever.

Turn the ignition key to any position other than «LOCK» (blocking), and shift the selector lever while depressing the brake pedal and pressing the release button.

Switch the selector lever without pressing the release button.

Switch the selector lever while pressing the lock button.

If a malfunction is detected during the above checks, adjust the ignition lock cable as described below.

Remove the floor console drawer.

Switch the selector lever to position P (Parking).

Turn the ignition key to the LOCK position (blocking)

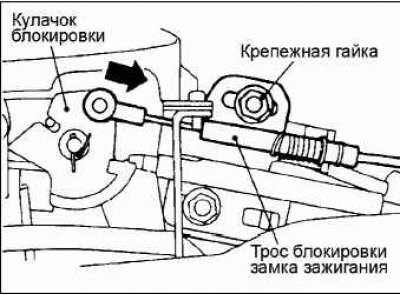

Loosen the fixing nut of the ignition lock cable.

Lightly pressing the cable connected to the locking cam in the direction of the arrow, tighten the fixing nut.

Install the floor console box.

If the above test reveals a malfunction, adjust the shift lock cable.

Remove the floor console drawer.

Switch the selector lever to position «R» (Parking).

Loosen the fixing nut of the ignition lock cable.

Tighten the mounting nut when the end of the shift lock cable reaches the red mark on the lock cam.

Install the floor console box.