Disassembly

Parts that have been assembled with sealant can usually be easily disassembled without the use of special tools. However, in some cases, the sealant between the surfaces to be joined can be destroyed by light tapping with a mallet or similar tool. In this case, care must be taken not to damage the bonded surfaces.

Surface preparation for sealant application

Using a scraper or iron brush, thoroughly clean the surfaces to be sealed. The surface to which the sealant will be applied must be flat. Clean the surface of oil and foreign materials. Be sure to remove any old sealant from the bolt holes.

Rules for the use of sealants

When assembling parts with a sealant, you must follow some rules that are quite simple. The sealant bead must be continuous and free of gaps. Always enclose bolt holes completely with sealant. Excess sealant can be wiped off before it hardens. While the sealant has not yet hardened (less than 15 minutes) install the parts to be joined. After installing the parts, make sure that the sealant gets only in the right places. Do not allow oil or water to come into contact with the sealant and do not start the engine until a sufficient amount of time has elapsed (about 1 hour) after assembly.

The procedure for using sealant for different places may be different. Therefore, when using sealant, you must follow the rules below in the text.

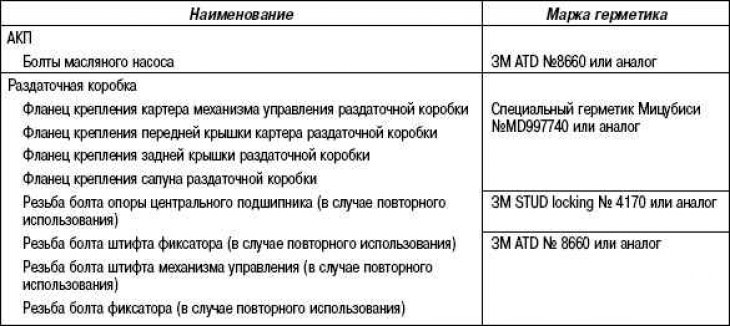

Used sealants