The evaporative emission system, as its name suggests, is designed to prevent fuel vapors generated in the fuel tank from escaping into the atmosphere. From the fuel tank, the fuel vapors are directed through the fuel tank pressure control valve and the fuel vapor suction hose/pipe to the adsorber, where they are absorbed by the activated charcoal. When the car is moving, the fuel vapors accumulated in the canister through the canister purge solenoid valve, the vacuum hose and the throttle body fitting are sent to the intake manifold and then burn out in the combustion chambers of the engine cylinders. When the coolant temperature is low or the air flow is low (e.g. at idle) the engine control unit turns off the solenoid valve and the latter blocks the flow of fuel vapor into the intake manifold. This not only keeps the engine running smoothly when it is cold or running under light load, but also reduces (literally: stabilizes, approx. red-ra) release of toxic substances.

Checking the adsorber purge system

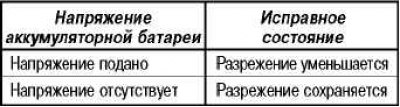

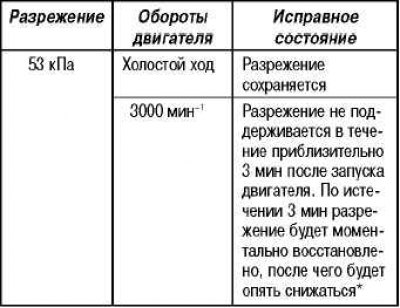

|  |

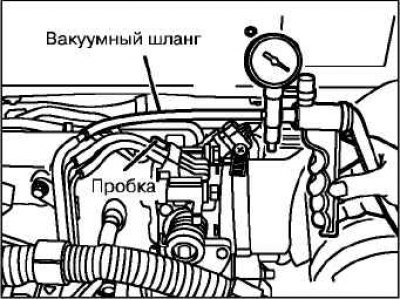

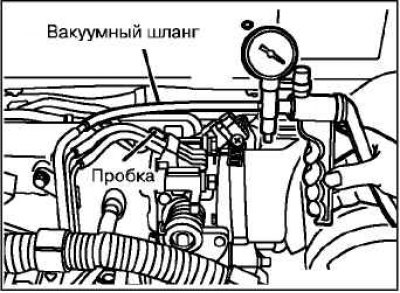

Disconnect the vacuum hose from the throttle body (with red stripe) and connect a hand vacuum pump to it. Plug the fitting from which the vacuum hose was removed. Apply a vacuum with the pump when the engine is cold or warm at idle, and check the condition of the engine and the vacuum.

Engine is not warm (Coolant temperature not more than 40°C)

Engine warmed up (Coolant temperature not less than 80°С)

* The vacuum will decrease continuously if the absolute value (barometric) pressure of approximately 77 kPa or less, or an intake manifold air temperature of approximately 50°C or more.

Checking the canister purge vacuum hose fitting

Disconnect the vacuum hose from the throttle body (with red stripe) and connect a hand vacuum pump to the fitting of the removed hose.

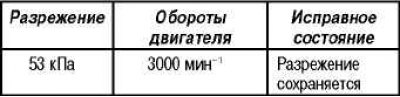

Start the engine and check that as the engine speed increases, the vacuum increases proportionally.

Note. If the vacuum does not increase or increases slightly, the nozzle in the throttle body is probably clogged, so clean the nozzle hole.

Checking the canister purge solenoid valve

Note. When disconnecting vacuum hoses, always pre-mark alignment marks so that the hose is in its original position when connected.

|  |

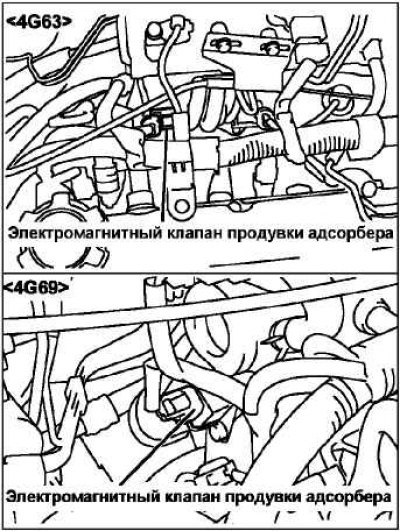

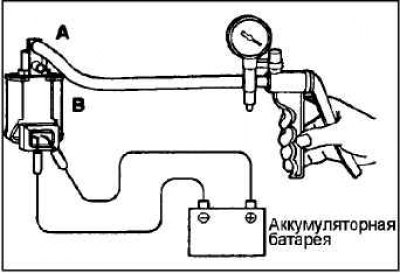

Disconnect the vacuum tubes from the canister purge solenoid valve (with black and red stripes).

Disconnect the electrical connector.

Connect to fitting (A) canister purge solenoid valve manual vacuum pump (as it shown on the picture).

Check valve operation (creating a vacuum with a vacuum pump) when connecting / disconnecting wires from the battery terminals to the valve terminals.

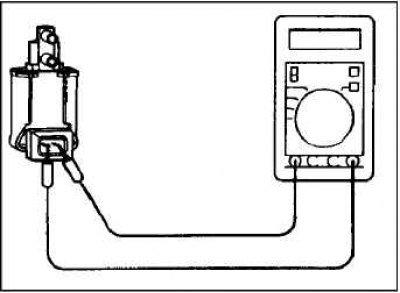

Measure the resistance between the terminals of the canister purge solenoid valve connector.

Rated value: 36-44 ohms (at 20°C).