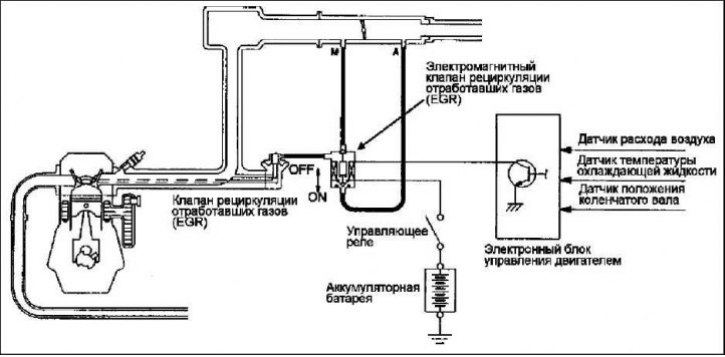

Exhaust gas recirculation system (EGR) reduces emissions of nitrogen oxides (NOx). At a high temperature of the air-fuel mixture burning in the combustion chamber, a large amount of nitrogen oxides is formed (NOx). The exhaust gas recirculation system directs part of the exhaust gases from the cylinder head outlet through the intake manifold back to the combustion chambers, thereby lowering the combustion temperature of the air-fuel mixture, resulting in a decrease in the concentration of nitrogen oxides. The degree of exhaust gas recirculation is controlled by the EGR valve (EGR), so as not to impair the stability of the engine.

How the system works

|  |

EGR valve (EGR) closed and EGR does not occur under one of the following conditions: In all other modes, the EGR valve (EGR) open and exhaust gas recirculation takes place.

Checking the exhaust gas recirculation system (EGR)

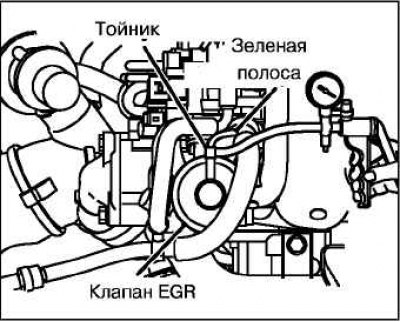

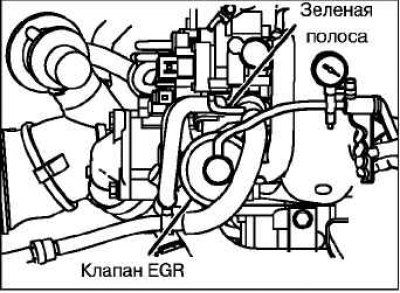

Disconnect the vacuum hose (with green stripe) from the EGR valve and connect a hand vacuum pump to it through a tee.

By increasing the speed on a cold and warm engine, check the vacuum condition.

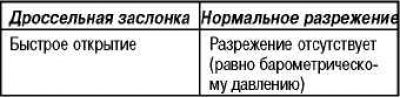

Cold engine (Engine coolant temperature not more than 20°С)

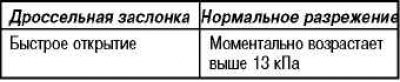

Warm engine (Engine coolant temperature not less than 80°С)

Disconnect the adapter tee.

Connect a hand vacuum pump to the EGR valve.

Check if the engine idle becomes erratic and stalls if you apply a vacuum of 30 kPa or more.

Exhaust Gas Recirculation Valve Check (EGR)

Remove the EGR valve and check for valve stem sticking, deposits, etc. If abnormalities are found, clean the valve with an appropriate solvent to ensure that the valve stem seats properly.

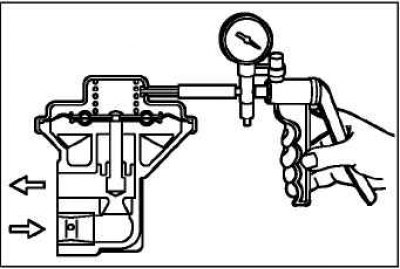

Connect a hand vacuum pump to the EGR valve.

Create a vacuum of 67 kPa and check if it is maintained.

Apply a vacuum and check if air is passing through the EGR valve.

Replace the valve gasket and tighten the screws to the specified torque.

Tightening torque: 22 Nm.

Checking the EGR Vacuum Hose Fitting

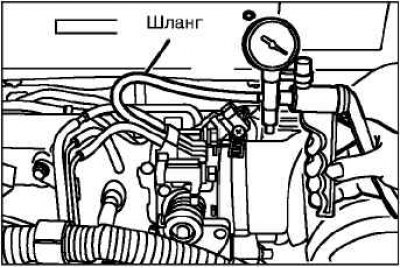

Disconnect the vacuum hose (with white stripe) from the fitting on the throttle body and connect a hand vacuum pump to it.

Start the engine and check that the amount of vacuum remains constant as the engine speed increases.

Note. If the vacuum value changes with increasing engine speed, then the EGR fitting in the throttle body is probably clogged, which needs to be cleaned.

Checking the solenoid valve of the EGR system

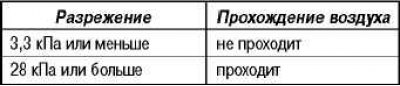

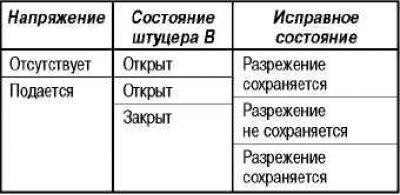

|  |

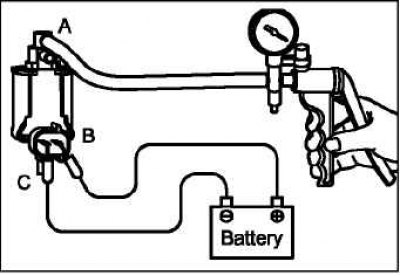

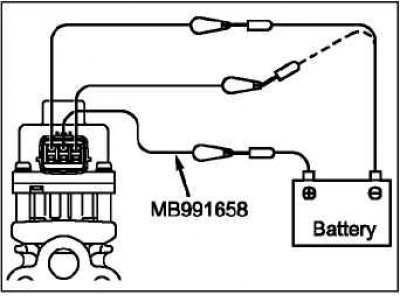

Disconnect the vacuum hoses (with yellow, white and green stripes) from the solenoid valve.

Note. When disconnecting vacuum hoses, always pre-mark alignment marks so that the hoses are set in their original position when connected.

Disconnect the electrical connector.

Connect a hand vacuum pump to the union where the hose with the white stripe was put on.

Check the operation of the valve by creating a vacuum with the battery disconnected and connected to the valve terminals.

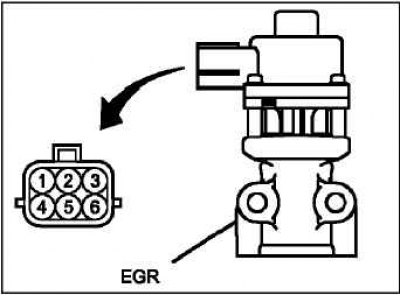

Checking the EGR valve servo (4G69 engine)

Check that the sound of the EGR valve servo is clearly audible (stepper motor) when the ignition is turned on (without engine start).

If no sound is heard from the EGR valve servo, check the servo power circuits. If the power supply circuit is working, then the servo itself or the electronic engine control unit may be faulty.

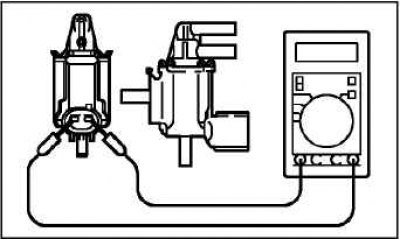

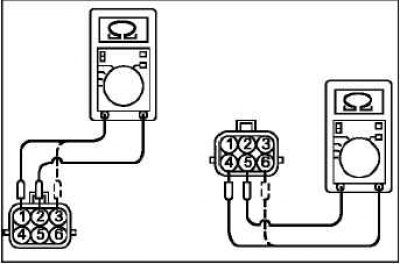

Checking the resistance of the servo winding

Disconnect the EGR valve servo connector.

Measure the resistance between the terminal «2» and conclusions «1» or «3» servo connector.

Rated impedance: 20-24 ohms (at 20°C).

Measure the resistance between the terminal «5» and conclusions «4» or «6» servo connector.

Rated impedance: 20-24 ohms (at 20°C).

Replace the gasket and tighten the valve mounting bolts to rated torque.

Tightening torque: 24±3 Nm.

Checking the operation of the servo

Remove the EGR valve servo.

Connect the test harness to the EGR servo connector.

Connect the wire from the positive terminal of the power supply (voltage approx. 6 V) to the conclusion «2» servo connector.

Connect a wire from the negative terminal of the 6V power supply to the terminals «1» And «3» connector. At the same time, check if you can feel a slight vibration of the running stepper motor.

Connect the wire from the positive terminal of the power supply (voltage approx. 6 V) to the conclusion «5» servo connector.

Connect a wire from the negative terminal of the 6V power supply to the terminals «4» And «6» connector. At the same time, check if you can feel a slight vibration of the running stepper motor.

If, as a result of these checks, a slight vibration of a working servo is felt, then it is considered serviceable.

Replace the gasket and tighten the valve mounting bolts to rated torque.

Tightening torque: 24±3 Nm.

Cleaning the EGR valve

Remove and inspect the EGR valve for sticking or blockage. If necessary, clean the valve with a wire brush.

Attention! Do not use solvent for cleaning, as it may cause malfunctions if it gets on the servomotor.

Replace the gasket and tighten the valve mounting bolts to rated torque.

Tightening torque: 24±3 Nm

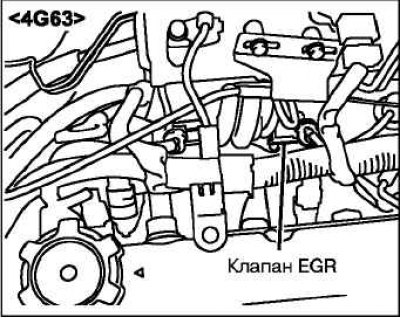

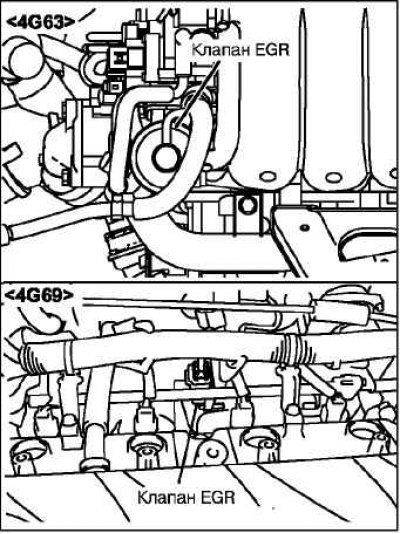

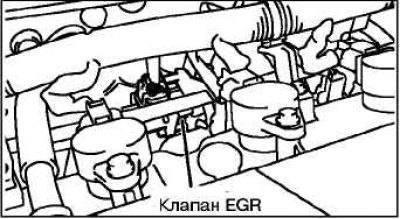

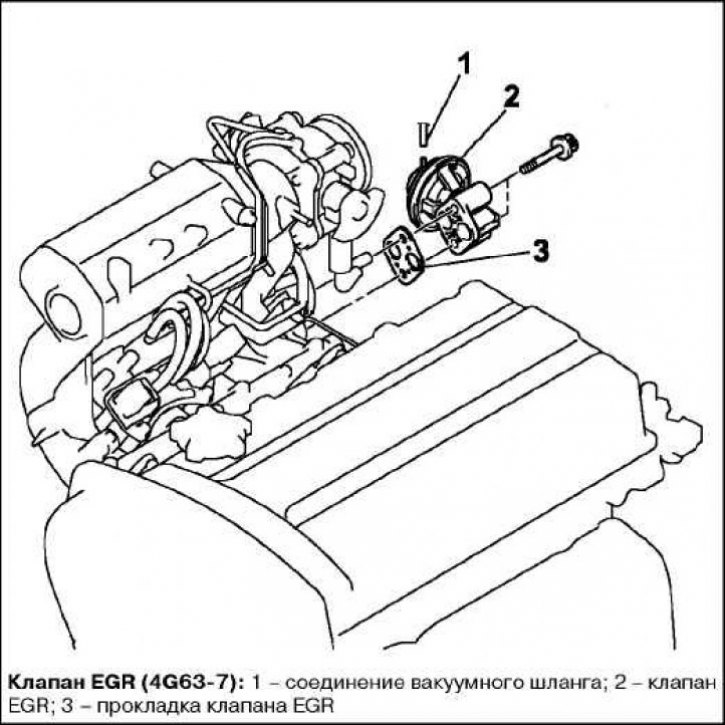

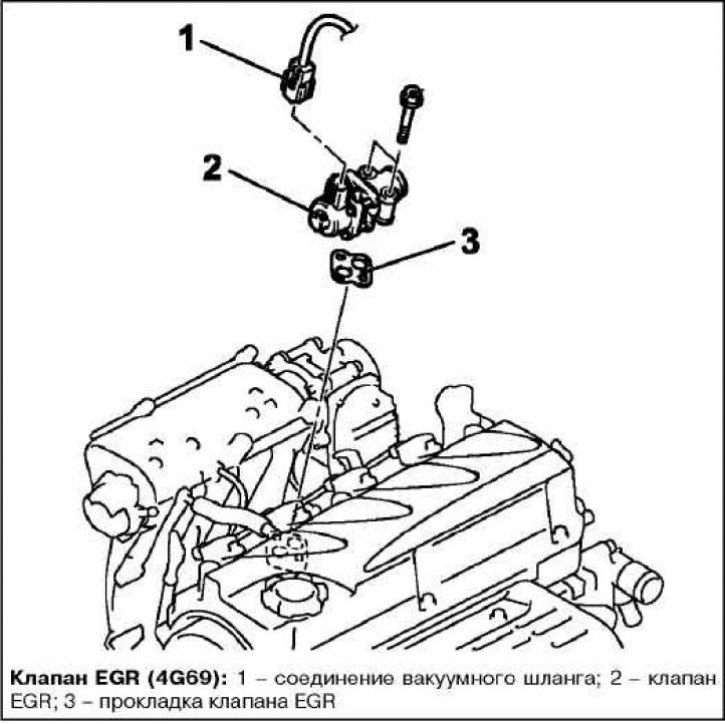

Removing and installing the EGR valve

Remove the air filter cover and air inlet hose (4G63-7).

Remove the resonator (4G69).

Installation of details is made in an order, the return to removal.

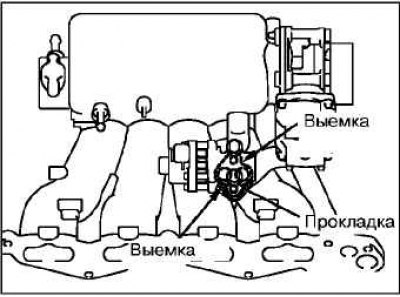

When installing the parts, pay attention to the installation procedure of the EGR valve gasket.

Install the valve gasket with the notched sides as shown.

Install the air filter cover and air inlet hose.

Install the resonator.