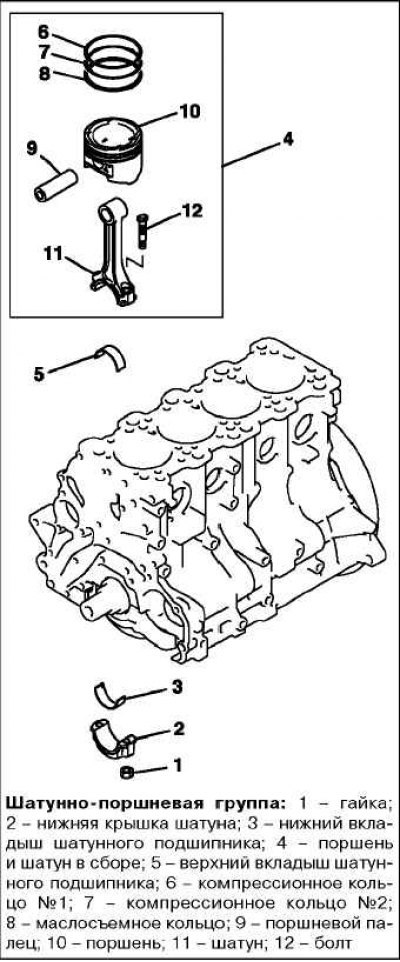

Note. The disassembly and assembly of the connecting rod and piston group is carried out using a special tool (kit for assembly and disassembly of piston kits).

|  |

Removing the piston and connecting rod

Loosen the nut, remove the connecting rod cap and remove the piston and connecting rod from the cylinder.

Attention! When removing the piston and connecting rod assembly, be careful not to damage the cylinder surface and the crankshaft journal with the connecting rod.

Mark the cylinder number on the side of the connecting rod for ease of reassembly.

Position the removed parts (connecting rods, pistons, liners, etc.) in order of their correspondence to cylinder numbers, for the correctness of subsequent assembly.

Checking the piston and piston pin

Attention! The piston and piston pin are replaced as a repair kit.

Carefully inspect the piston, replace it if there are scratches or burrs on the working planes (especially on hard surfaces).

Press the piston pin into the piston bore with thumb force. There should be resistance to this. Replace the pin if it slides easily into the hole or there is noticeable play.

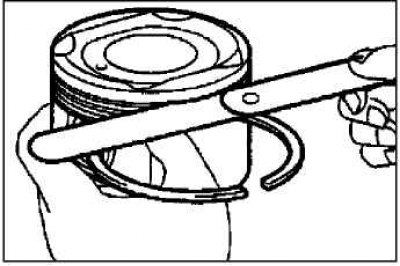

Piston rings

Attention! Old piston rings are replaced with new ones if a new piston is installed.

Check the piston rings for damage, kinks or noticeable wear.

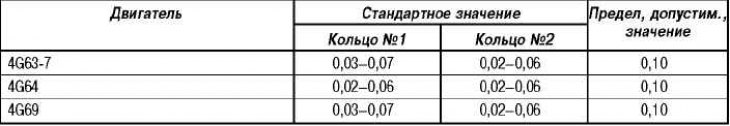

Measure the clearance between the piston ring and the piston groove. If the gap exceeds the allowable value, then replace the ring, piston or both parts together.

Note. Remove carbon deposits from all piston grooves before taking measurements.

Note. Measure the clearance between the ring and the piston groove over the entire circumference of the ring.

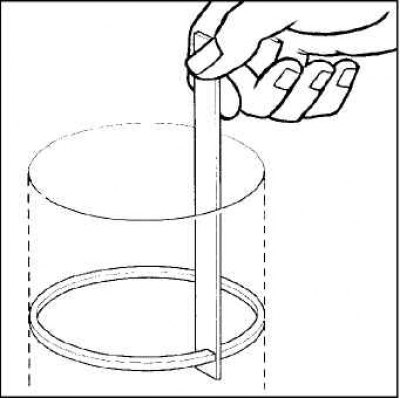

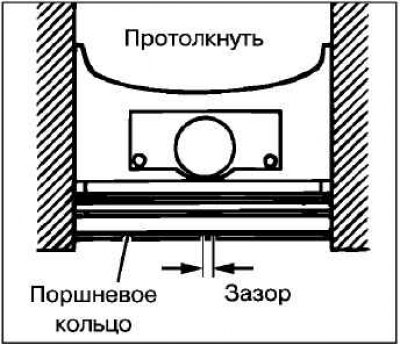

Install the piston ring in the cylinder bore. Move the ring with the piston as shown in the figure so that the ring is at right angles to the generatrix of the cylinder wall.

Measure the gap in the lock of the ring, if the gap is greater than the allowable value (see corresponding table), replace the ring.

Checking the gap between the compression ring and the groove under it (mm)

Checking the clearance in the piston ring lock (mm)

Checking the condition of the connecting rod bearing shells

Visually inspect the condition of the surface of the connecting rod bearing for uneven contact, scratches and burrs). In case of defects, replace the connecting rod bearing shells.

If the defects are significant, check the corresponding crankshaft journals. If there are defects on the crankshaft journals, replace the crankshaft.

Checking the clearance in the connecting rod bearing

Measure the inner diameter of the connecting rod bearing and the outer diameter of the connecting rod journal of the crankshaft, then determine the clearance in the connecting rod bearing. A plastic gauge is usually used to measure the clearance in a connecting rod bearing.

Nominal outer diameter of crankshaft journal: 45.0 mm.

If the oil clearance exceeds the limit, replace the connecting rod bearing shells, crankshaft, or both.

Measuring the clearance in the connecting rod bearing with a plastic gauge

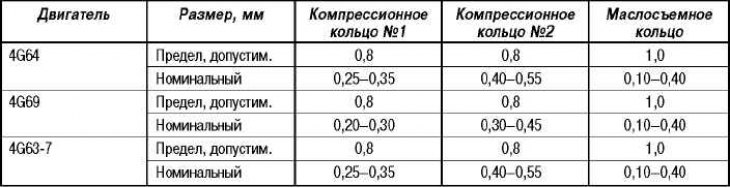

Clean the crankshaft journals and bearings of oil and dirt.

Cut a piece of plastic gauge as long as the bushing width and place it parallel to the axis of the shaft journal away from the oil passage hole.

Install the bearing and connecting rod cap and tighten the nuts.

Note. Do not turn the crankshaft.

Remove the cover and use the scale printed on the package of gauges to determine the clearance in the bearing.

Gap in connecting rod bearing

- Nominal: 0.02 - 0.05 mm.

- Maximum allowable: 0.10 mm.

Connecting rod check

Install the connecting rod bushing and piston pin into the connecting rod if removed.

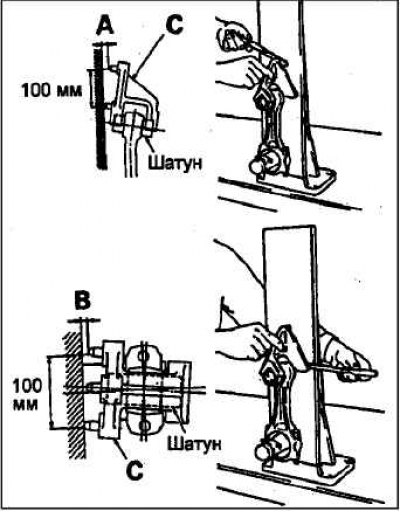

Using a special connecting rod test stand «WITH» and a flat feeler gauge, check for bending and twisting of the connecting rod as shown in the illustration.

Limit value (per 100 mm length):

- bend: 0.05mm;

- twist: 0.10 mm.

Attention! Install the connecting rod in a special stand «WITH» together with the upper and lower connecting rod bearing shells installed.

Tighten the connecting rod cap bolts according to the special procedure.

Connecting rod length: 149.9-150.0mm, connecting rod length is the distance between the centers of the upper and lower connecting rod heads.

If the bending or twisting of the connecting rod exceeds the limit, replace the connecting rod assembly with the cover.

Piston pin selection

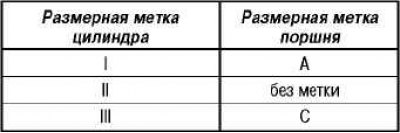

|  |

Attention! If the engine cylinders have not been machined, if it is necessary to replace the piston, select it so that the mark on the top matches the cylinder size mark on the cylinder block according to the table below.

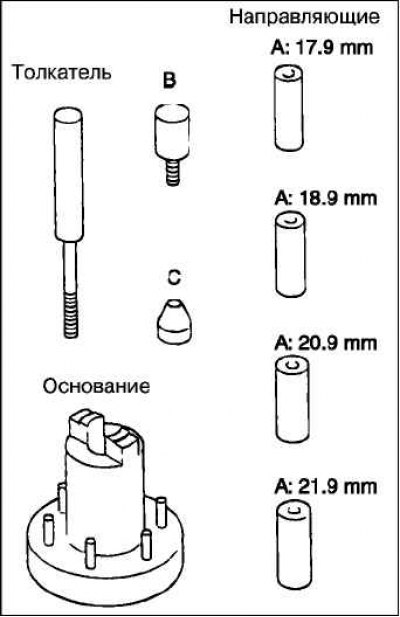

Piston pin replacement

Note. The disassembly and assembly of the connecting rod and piston group is carried out using a special tool (kit for assembly and disassembly of piston kits).

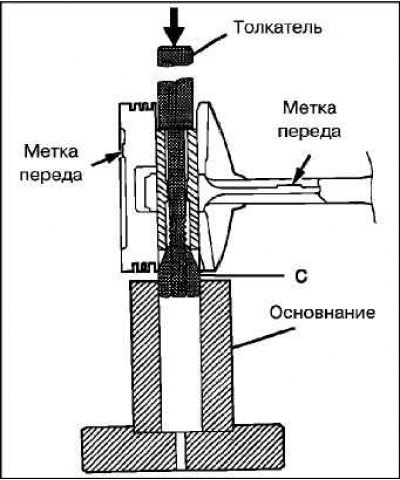

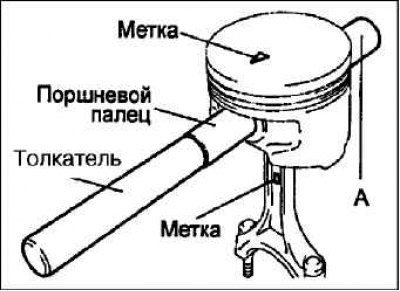

Insert the push rod into the piston from the side of the label «front» (in the form of an arrow), applied to the bottom of the piston.

Install the piston and connecting rod on the base with marks «front» up as shown.

Using a press, remove the piston pin.

Note. To facilitate reassembly, keep disassembled parts separate from other similar parts.

Preparing the Special Tool

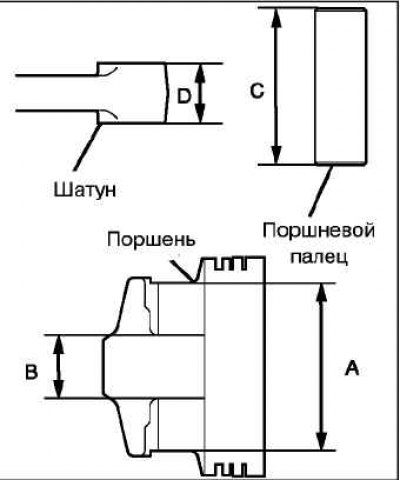

Measure the following quantities:

- «A» - the length of the hole for the piston pin;

- «IN» - the distance between the piston bosses;

- «WITH» - the length of the piston pin;

- «D» - the width of the upper head of the connecting rod.

Determine the value «L» in the manner described below.

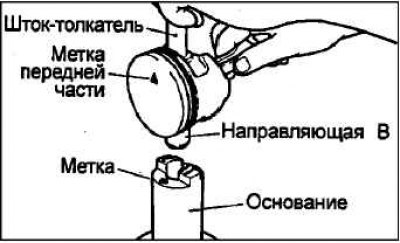

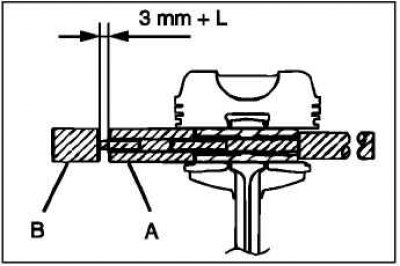

Put the piston pin on the pusher rod and screw the guide sleeve «A» at the end of the stem.

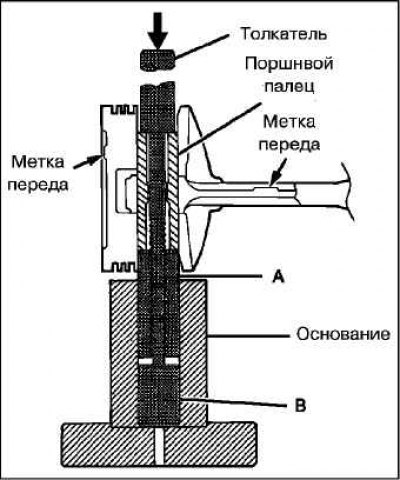

Place the piston and connecting rod together with marks «front» up to the base of the fixture. Lubricate the surface of the piston pin with a thin layer of engine oil. Install Node (push rod with piston pin and guide sleeve «A» complete) sleeve in the combined hole of the piston and connecting rod (for piston pin) from the label side «front».

Screw in the guide bush «IN» into the guide bush «A» so that between these guide bushings a distance is formed equal to that measured in subparagraph (e) size «L» + 3 mm.

Place the piston and connecting rod together with marks «front» up on the base of the fixture, n) Press down on the pusher rod to install the piston pin. If the force developed during pressing is less than the nominal value, then replace the piston with a piston pin assembly and / or connecting rod.

- Standard pressing force: 7350–17200 N.

- Piston pin nominal outer diameter: 22.0 mm.

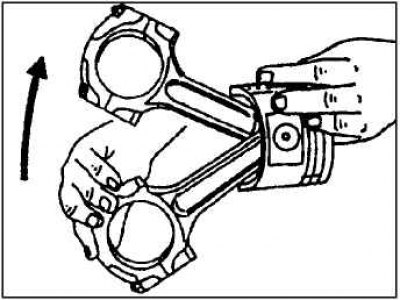

Check that, after reassembly, the piston can swing freely on the connecting rod when moved in the direction of the arrow.