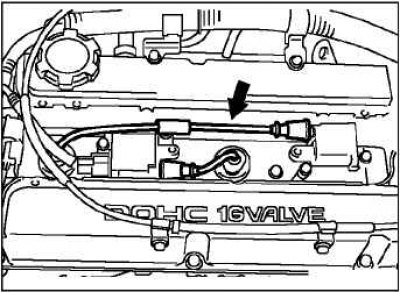

Checking for damage on high voltage wires

Check the high-voltage wires and spark plug tips for damage, weakening of the clamping force of the contacts, and also check that they are installed correctly.

Check for dirt on the contacts of high voltage wires, spark plugs and ignition coils, etc.

If there is contamination, clean, if the elements are damaged, replace them.

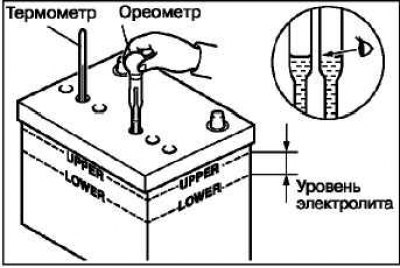

Checking the electrolyte level in the battery

Check if the electrolyte level is between the high and low level marks.

Warning! If the electrolyte level is below the low level mark, the battery may explode during use.

Attention! If the electrolyte level is above the high level mark, electrolyte leakage may occur.

Use a thermometer and a rheometer to check the electrolyte density.

Standard value: 1.220 - 1.290 (at 20°C).

The density of an electrolyte changes with temperature, so the following formula is used to convert density values to a specific temperature. In order to determine the acceptability of a given electrolyte density, use the calculated value.

D20 = (t – 20) x 0.0007 + Dt D20: electrolyte density normalized to 20°C. Dt - oreometer readings t - thermometer readings.

Visual check of elements of system SRS

Set the ignition key to position «LOCK», disconnect the negative cable from the battery and insulate it.

Attention! Wait at least 60 seconds after disconnecting the battery before proceeding with further work.

Front impact sensors

Check for rust on the headlight mounting panel.

Make sure that there are no signs of rust or mechanical damage on the body of the front impact sensors.

Check the condition of the sensor wiring harness for pinching. Check for damage and deformation on connectors and leads.

Side impact sensors

Check for rust and deformation on the B-pillar

Make sure that there are no signs of rust or mechanical damage on the body of the side impact sensors.

Check the condition of the sensor wiring harness for pinching. Check for damage and deformation on connectors and leads.

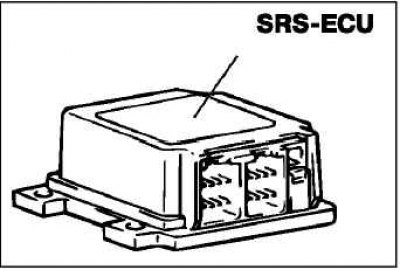

SRS electronic control unit

Check for dents, rust, and cracks on the brackets and SRS-ECU housing.

Warning! If the SRS-ECU is installed incorrectly, the secondary security system may not work, resulting in serious injury or death to the driver and front passenger.

Check for damage and corrosion on the connectors. Replace the SRS-ECU if defects are found during the inspection.

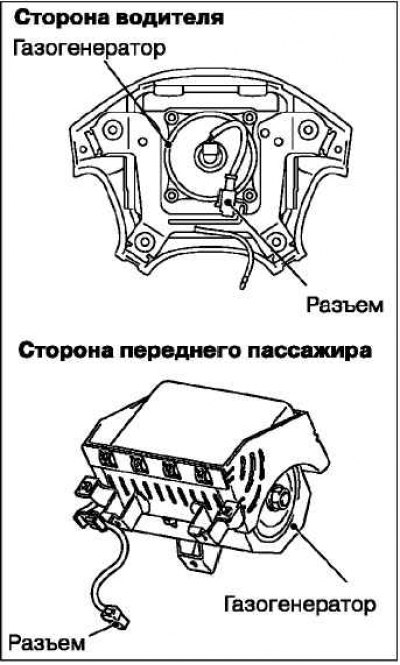

Airbag module, steering wheel and clock spring

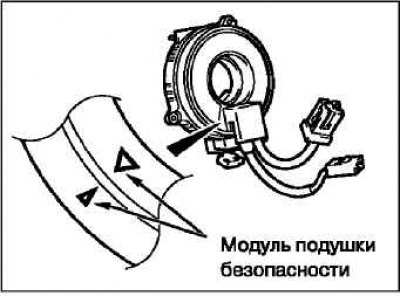

Remove the airbag modules, steering wheel and clock spring.

Attention! The removed airbag module must be stored in a clean, dry area, face up.

Check for dents, cracks, deformations on the front surface (sheathing) module.

Check for damage to the connectors, deformed pins, and kinks in the wiring harness.

Check for dents, cracks, deformations on the gas generator.

Check for damage to the connectors and wiring harnesses, deformation of the contacts.

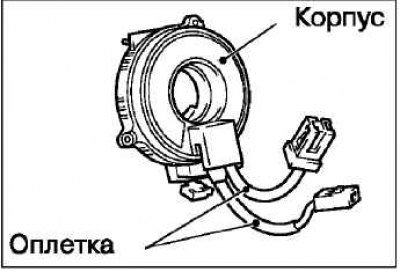

Check for damage to the connectors and braid, deformation of the contacts of the clock spring.

Visually inspect the clock spring housing for damage.

Attention! If damage is found, these parts must be replaced.

Check for excessive play in the steering wheel.

Align the timing marks on the dial spring and install it by turning the steering wheel to the straight ahead position.

Alignment marks

Turn the dial spring fully clockwise, then back it 3/4 turns and align the timing marks.

Warning! If the timing marks of the dial spring are not exactly aligned, the steering wheel will not turn fully when turning, or the flat wire contained in the dial spring may be damaged, preventing the SRS system from working properly, and this could possibly lead to serious injury to the driver or front passenger.

Install the steering column covers, steering wheel and air bag module.

Check for noise and jamming when turning the steering wheel.

Warning! If one of these items is incorrectly installed, the SRS system may not work, resulting in serious injury or death to the driver and front passenger.

Front seat with side airbag

Check for dents or deformations on the side airbag module.

Check for damage to connectors, deformed pins, and kinks in wire harnesses.

Seat belts with pretensioners

Check for dents or deformations on the seat belt pretensioner.

Check the correct installation of the pretensioner on the car body.

Instrument Panel Wiring Harness/ Car Front Wiring Harness/ Floor Wiring Harness

Warning! The SRS system will not be able to be activated if the SRS wiring harnesses or connectors are damaged or not properly connected; this, in turn, can lead to serious injury to the driver and passengers.

Check after installation of elements of the SRS system

Reconnect the negative cable to the battery. Turn the ignition key to the ON position. Does the SRS warning light come on for about 7 seconds, turn off, and then come back on for at least 5 seconds? If so, then the SRS system is OK.