This section is devoted to the description of maintenance and repair procedures for some elements of the on-board electrical system. In addition, the procedures for diagnosing malfunctions of electrical equipment of a general order are considered.

The vehicle is equipped with a Controller Area Network multiplexed communication device (CAN). It combines individual control devices into a common circuit (data bus), which gives the following advantages: fast data transfer from one device to another, saving space due to the use of small boards and parts, reducing the number of sensors due to their multifunctionality.

The principle of CAN operation: instead of a separate conductor, only two common wires are used for each signal, which allows you to simultaneously receive information about the status of most devices and sensors without using separate toggle switches and switches.

CAN bus receiving important information (for example, about a malfunction), fixes it in its memory.

Attention! When replacing fuses, it is forbidden to use screwdrivers and metal tools, as this can lead to a short circuit in the circuits of electrical equipment.

Attention! It is forbidden to disconnect the ignition switch and the battery while the engine is running, as this will lead to failure of the voltage regulator and elements of the vehicle's electronic equipment.

Attention! When checking the circuits of electrical equipment, it is forbidden to short to «mass» wires (check the continuity of the circuits «for a spark»), as this can lead to failure of electrical components.

Attention! Do not even briefly connect the output «30» generator with «weight» (check the generator «for a spark»), as this will lead to failure of the generator rectifier unit diodes. You can only check the alternator on a car with a voltmeter and an ammeter. In order to avoid failure of the rectifier unit diodes, it is forbidden to check them with a megohmmeter or a test lamp powered by a voltage of more than 12 V, and also to check the electrical equipment circuits on the car with such devices without disconnecting the wires from the generator. It is necessary to check the insulation resistance of the generator stator winding with increased voltage on the generator removed from the vehicle, with the stator winding terminals disconnected from the rectifier unit.

Attention! When carrying out electric welding work on a car, it is necessary to disconnect the wires from the battery terminals and the generator.

Attention! Do not touch the elements of the ignition system and high-voltage wires while the engine is running.

Attention! Do not run low voltage and high voltage wires in the same bundle.

Attention! When recharging the battery in a car using a charger, disconnect the wires from the battery terminals.

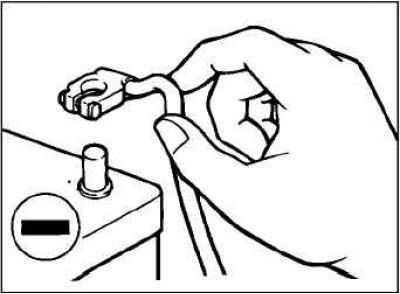

Attention! Before connecting or disconnecting the negative terminal from the battery, make sure that the ignition and parking lights are turned off. (Otherwise, semiconductor elements may be damaged).

Preparing the car for the performance of control and diagnostic operations

Term «condition of the car before the start of control and diagnostic operations» means that the condition of the vehicle before starting the test must meet the requirements below.

Coolant temperature: 80-90°C.

Headlights, electric cooling fan, and all other auxiliary electrical consumers must be switched off.

Manual transmission: in neutral position.

Automatic transmission: in mode «R».

Spray water temperature: no more than 82°С.

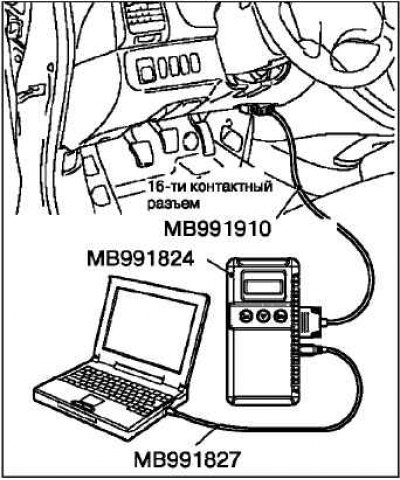

Checking with the MUT-II

Connect the MUT-II device to the diagnostic connector as shown in the figure.

Attention! Before connecting or disconnecting the MUT-II, make sure the ignition key is turned to the «LOCK» («OFF»).

To prevent car fire

Incorrect installation of electrical or fuel system components may cause a fire. In order to ensure the high quality and safety of the vehicle, it is necessary that the installation of any additional equipment, as well as repairs related to the electrical or fuel system, must be carried out in accordance with «Repair manuals».