Attention! Do not remove the tie rod end nut from the ball joint. Loosen it when using the special tool to avoid possible damage to the threads of the ball joint.

|  |

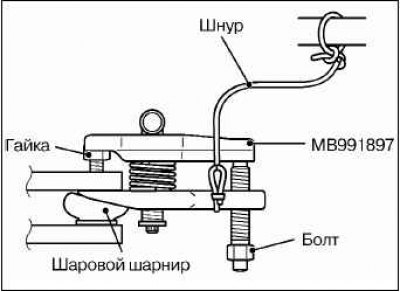

Hang the special tool with a cord to prevent it from falling.

Install the ball joint puller (MV991897) as shown in the figure.

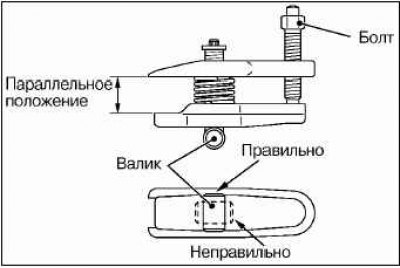

After setting the clamping plates of the special tool parallel to each other by turning the bolt and adjusting knob, tighten the bolt by hand and finally make sure that the clamping plates are parallel to each other.

Note. When installing the clamping plates in parallel, make sure that the handle of the tool is in the position shown in the figure.

Tighten the tool bolt with a wrench to disengage the tie rod end.

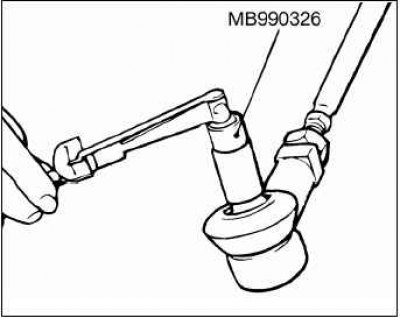

Grasp the threaded part of the ball joint stud with your hand, turn the joint several times, then screw the nut onto its threaded part. With a torque wrench (MV990326), measure the moment when the ball joint begins to rotate.

Rated value: 0.5 - 2.5 Nm.

If the measured torque value exceeds the nominal value, replace the tie rod end.

If the measured value is less than the nominal value, check that the ball joint rotates freely, without significant play and binding. If there is no end play or seizing, the ball joint is reusable.

Attention! In this case, it is necessary to change the ball joint nut for a new one each time, since this nut is self-locking.

Connect the tie rod end to the steering knuckle, tighten the connection with a self-locking nut to the nominal torque.

Rated tightening torque: 25 + 5 Nm.