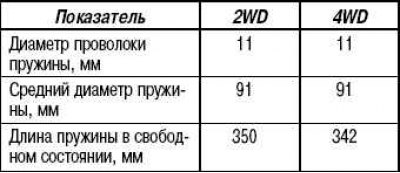

Specifications (helical coil spring)

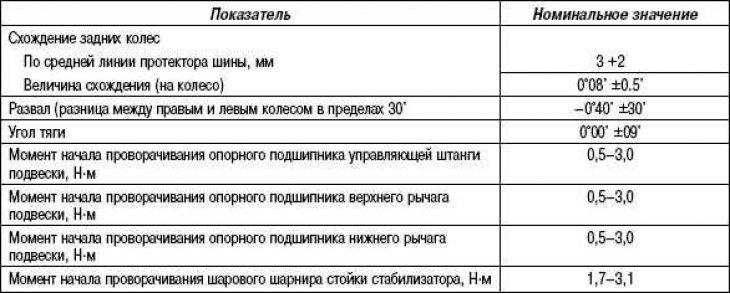

Basic data for regulation and control

* The difference between the right and left wheels should not be more than 30'.

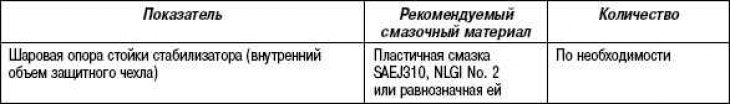

Lubricants

Technical operations on the car

Attention! With loose nuts of the shafts of the wheel hubs (self-locking nuts) or loose fixtures to check drive wheel alignment (MV991014), checking the wheel bearings is not allowed.

Attention! For vehicles with aluminum alloy wheels: attach a wheel alignment gauge to the wheel drive shaft using the special tool (MV991014). Fasten the special tool with the same tightening torque 175±25 Nothing and the rear wheel hub nut (self-locking nut). If the camber is out of specification, perform the following operations.

Disconnect the control rod from the trailing arm.

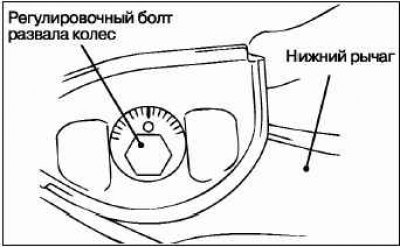

Adjust the camber by turning the adjusting bolt (lower suspension arm mounting bolt located on the inside of the body).

- LH: Clockwise from the front of the vehicle (+) collapse.

- RH: Clockwise from the front of the vehicle (–) collapse.

- The scale has a division value of about 14'.

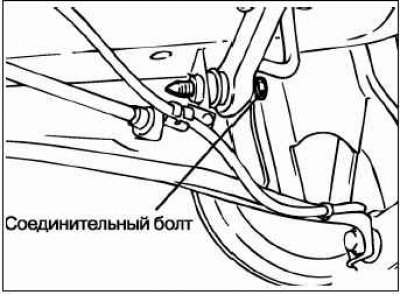

To prevent the destruction of the bushings, the connecting bolt is first pre-tightened, then finally tightened to a torque of 90 + 10 Nm, and the unladen vehicle must be on the ground.

Attach the control rod to the trailing arm.

After adjusting the camber, adjust the wheel alignment of the car.

Convergence

Nominal value: in the center line of the tire tread, 3 +2 mm.

Convergence (on the wheel): 0°08±0,5’.

If the toe-in is out of specification, adjust it as follows.

Attention! To prevent the destruction of the bushings, the control rod fastening nut is first pre-tightened, then finally tightened to a torque of 120 + 10 Nm, and the unladen vehicle must be on the ground.

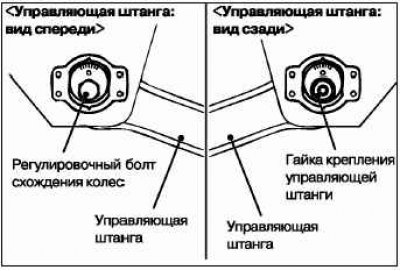

Control rod: front view»

Adjust the toe by turning the adjusting bolt (suspension control rod mounting bolt located on the inside of the body).

- LH: Clockwise from the front of the vehicle (+) convergence.

- RH: Clockwise from the front of the vehicle (–) convergence.

- Turning the adjusting bolt one scale division changes the toe-in by 2.6 mm (one-sided toe angle corresponds to 16').

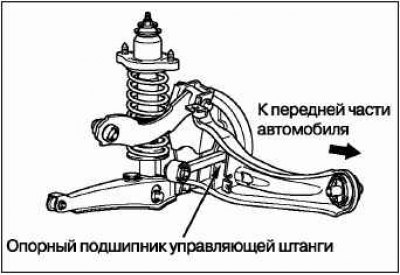

Checking the axial play of the support bearing of the control rod

Raise the vehicle.

Shaking the control rod up and down with your hand, check for axial play in the support bearing. If there is significant play, replace the control rod.

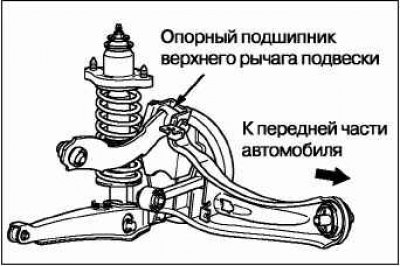

Checking the axial play of the support bearing of the upper suspension arm

Raise the vehicle.

Shaking your hand up and down the upper suspension arm, check for axial play in the support bearing. If there is significant play, replace the upper control arm.

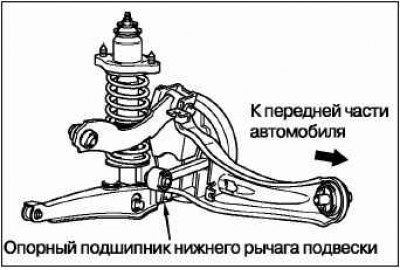

Checking the axial play of the ball joint of the lower suspension arm

Raise the vehicle.

Disconnect the anti-roll bar and shock absorber from the lower control arm.

Shaking your hand up and down the lower suspension arm, check for axial play in the support bearing. If there is significant play, replace the lower arm support bearing.

After checking, reconnect the stabilizer bar and shock absorber to the lower control arm.

Check of a condition of a protective cover of a spherical hinge of a rack of the stabilizer

Check the condition of the protective boots of the ball joint of the stabilizer strut for cracks and damage by squeezing the boots with your fingers.

If the protective cover is cracked or damaged, replace the stabilizer link assembly.

Attention! Cracks or damage in the protective boot can cause damage to the ball joint.