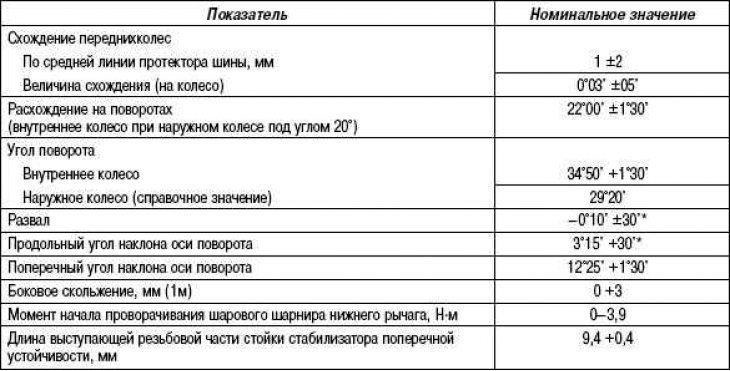

Specifications (helical coil spring)

Basic data for regulation and control

* The difference between the right and left wheels should not be more than 30'.

Lubricants

Checking and adjusting the angles of the front wheels

Measurement of wheel alignment angles using special equipment is carried out on a flat horizontal area. Before measuring wheel alignment, the condition of the front suspension, steering, tires and wheels should be checked.

Convergence

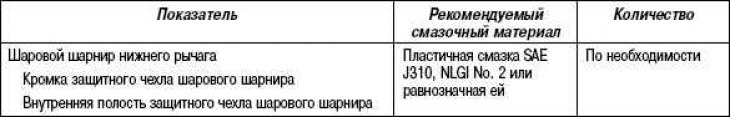

Adjust the toe of the front wheels by removing the clamping bar and unscrewing the lock nut, turning (in the opposite direction) the right and left turnbuckles of the transverse rods for the same distance.

Attention! The toe-in is reduced if the left turnbuckle is rotated towards the front of the vehicle, the right turnbuckle is rotated towards the rear of the vehicle.

Install the clamping bar and tighten the wheel locknut to the specified torque.

Rated tightening torque: 40 + 5 Nm

Make sure the toe value matches the nominal value.

Using a turn radius meter, check that the turn angle is within the rated value.

Divergence when turning

In order to check the condition of the steering linkages, especially for a vehicle that has been in an accident or suspected of having been in an accident, in addition to checking and adjusting the wheel alignment, it is necessary to check the steering discrepancy.

This check must be performed for both left and right turns.

Camber, longitudinal and transverse angles of inclination of the axis of rotation

Attention! The camber and rake angle are set at the factory and do not need to be adjusted.

When the nuts of the drive shafts are loose, checking the wheel hub bearings is not allowed.

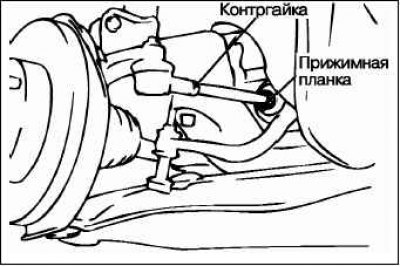

Attention! For vehicles with aluminum alloy wheels: attach a wheel alignment gauge to the wheel drive shaft using the special tool (MV991004). Fasten the special tool with the same tightening torque of 245±29 Nm as the drive shaft nut.

Checking the axial play of the ball joint of the lower arm

Raise the vehicle.

Disconnect the stabilizer bar link from the lower link.

By shaking the lever up and down with your hands, check for play in the axial direction of the ball joint. If there is significant play, replace the lower control arm assembly.

Checking the protective boot of the ball joint of the lower arm

Crimp the lower arm ball joint boot with your fingers to make sure it is not cracked or damaged.

If the ball joint boot is cracked or damaged, replace the lower control arm assembly.

Attention! The presence of cracks or damage to the protective cover of the ball joint, as a rule, is accompanied by damage to the ball joint.