Attention! When servicing disc brakes, special attention must be paid to meeting the technical requirements for disc brakes that ensure the normal operation of disc brakes. The following parameters must be checked before reworking or grinding the brake disc.

When servicing brake discs, care must be taken to check that the discs are within acceptable service limits to maintain normal brake operation.

Checking the degree of wear of brake pads and discs

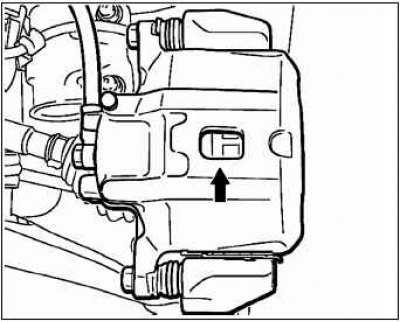

Check the thickness of the brake pads through the viewing window in the brake caliper.

- Nominal value: 10 mm.

- Limit value: 2.0 mm.

If the thickness of the working layer of the pad is less than the limit value, always replace the pads on the entire axle.

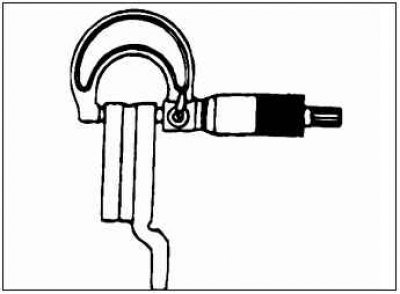

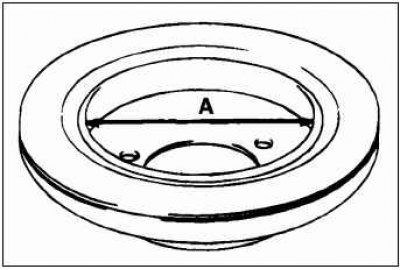

Use a micrometer to measure the thickness of the disc at eight points approximately 45°apart on the circumference and 10 mm from the outer edge of the disc.

- Rated value: 24.0 mm (front), 10,0 (rear).

- Limit value: 22.4mm (front), 8,4 (rear).

If the disc thickness is less than the limit, replace it.

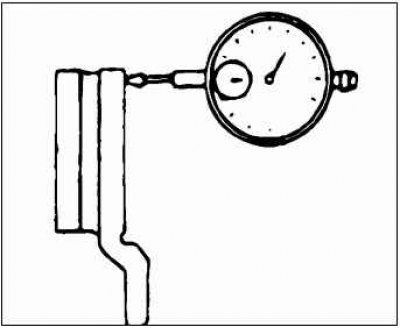

Disc runout check

Remove the brake mechanism assembly and hang it on a wire.

Temporarily install the disc on the hub nuts.

Set a dial indicator about 5 mm from the outer circumference of the disc and measure its runout.

- Limit value: 0.04mm (front), 0,05 (rear).

Checking the degree of wear of brake pads and drums

Remove the brake disc.

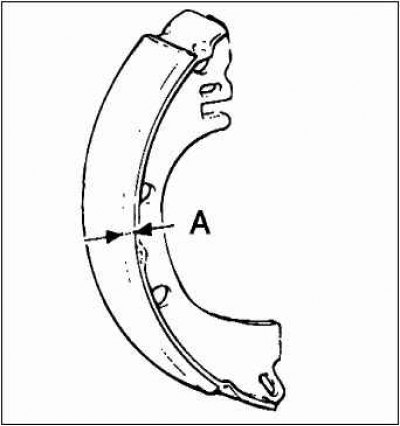

Measure the thickness of the friction lining.

- Rated value (A): 2.8 mm.

- limit value (A): 1.0 mm.

If the brake pad thickness is below the limit, replace the brake pads on both sides of the vehicle. It is not allowed to replace brake pads on one side.

Checking the thickness of the brake pads

Remove the brake drum.

Measure the thickness of the brake pad lining at the point of greatest wear.

- Nominal value: 4.4 mm.

- Minimum allowable value: 1.0 mm.

Replace the pad together with the lining if the thickness of the lining is less than the maximum allowable or if it is obviously worn.

Attention! When replacing the brake pads, it is necessary to change them both on the left and on the right side of the car, in order to prevent uneven braking of the right and left wheels.

If there is a significant difference in the degree of wear (thickness) brake pads on the left and right wheels, it is necessary to check the operation of the piston of the wheel brake cylinder.

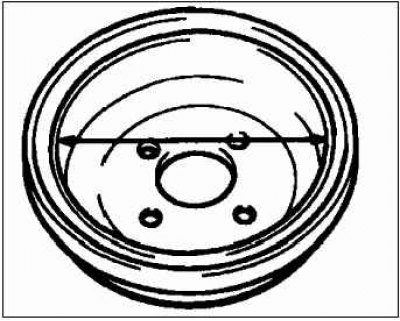

Checking the inner diameter of the brake drum

Remove the brake drum.

Measure the inside diameter of the brake drum at two or more locations.

- Nominal value: 203 mm.

- Maximum allowable value: 205 mm.

If the wear of the brake drum exceeds the limit value or the brake drum has a significant imbalance, then it is necessary to replace the brake drum and brake shoes.

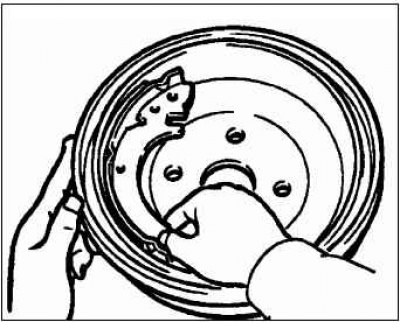

Checking the fit of the brake drum and brake shoes

Remove the brake drum.

Remove the brake pads.

Rub the inside of the drum with chalk and run the brake shoe over it.

If the contact patch is uneven, replace the brake drum or brake shoe.

Note. After checking, wipe off the chalk from the surface of the brake drum and lining.

Checking the inner diameter of the brake drum

Remove the brake drum.

Measure the inside diameter of the brake drum at at least two points.

- Rated value (A): 168.0 mm.

- limit value (A): 169.0 mm.

If the brake pad thickness is below the limit, replace the brake pads on both sides of the vehicle. It is not allowed to replace brake pads on one side.