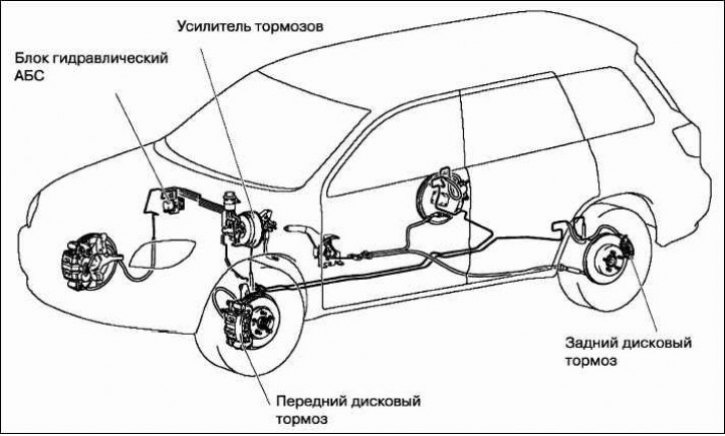

Mitsubishi Outlander cars are equipped with two independent brake systems: working and parking. The first system, equipped with a hydraulic drive, provides braking when the car is moving, the second one slows down the car in the parking lot, its drive is mechanical.

The car uses a working brake system with a diagonal separation of circuits, which significantly increases driving safety. If one of the circuits of the working brake system fails, the second circuit is used to stop the car, albeit with less efficiency. Both circuits are powered by a single pedal, which is attached to the body bracket. In addition to the brake pedal, the hydraulic drive includes a vacuum booster, a master brake cylinder, front and rear wheel brakes along with working cylinders, and pipelines.

The drive of the parking system is carried out on the brake mechanisms of the rear wheels.

Vacuum booster

Installed between the brake pedal mechanism and the brake master cylinder, when braking due to vacuum in the intake pipe (receiver) engine through the rod and piston of the first chamber of the main cylinder creates an additional force proportional to the force from the pedal. In the hose connecting the vacuum booster to the intake pipe (receiver), check valve installed. It holds the vacuum in the booster as it drops down the intake pipe and prevents the air-fuel mixture from entering the vacuum booster.

Master brake cylinder

The hydraulic brake master cylinder consists of two separate chambers connected to independent hydraulic circuits. The first chamber is connected to the right front and left rear brake mechanisms, the second - to the left front and right rear brake mechanisms.

The main cylinder is equipped with a tank, the internal cavity of which is divided into two compartments by a partition. Each compartment feeds one of the master cylinder chambers.

When you press the brake pedal, the pistons of the master cylinder begin to move, the working edges of the cuffs block the compensation holes, the chambers and the reservoir are separated and the brake fluid is displaced. On vehicles equipped with anti-lock brakes (ABS), pipe fittings are screwed into the holes of the master brake cylinder, supplying brake fluid to the ABS hydraulic unit.

On cars without ABS, pressure regulators are installed on the main brake cylinder, which, when braking, correct the pressure of the brake fluid in the rear brake mechanisms, excluding the possibility of pre-locking the rear wheels. This is achieved by proportionally reducing the pressure in the rear brakes relative to the pressure in the front.

Front brake

The brakes of the front wheels are disc, with automatic adjustment of the gap between the brake pads and the disc, with a floating caliper. The movable bracket is formed by a caliper with a single-piston working cylinder. The shoe guide is bolted to the steering knuckle of the front suspension. The movable bracket is bolted from below to the guide pin, which is installed in the hole of the guide shoe; from above, the bracket moves along the guide pin screwed into the shoe guide. The guide pin and pin are lubricated with grease and protected by rubber boots. A piston with a sealing ring is installed in the cavity of the wheel cylinder. Due to the elasticity of this ring, an optimal clearance is maintained between the pads and the ventilated disc, the surface of which is protected by the brake shield. When braking, the piston, under the influence of fluid pressure, presses the inner pad against the disc, as a result of the reaction force, the caliper moves on the fingers and the outer pad is also pressed against the disc, and the pressing force of the pads is the same. When releasing the piston, due to the elasticity of the sealing ring, it is removed from the pad, a small gap forms between the pads and the disc.

Rear brake

The brakes of the rear wheels are drum, with automatic adjustment of the gap between the pads and the drum. The brake pads are actuated by a single hydraulic working cylinder with two pistons. The optimal clearance between the drum and shoes is maintained by the mechanism for automatically adjusting the gap between the drum and shoes.

Parking brake

The parking brake is mechanically actuated and consists of a traction lever with an adjusting nut and two cables. The rear ends of the cables are connected to the parking brake release levers mounted on the rear brake shoes. The lever, fixed between the front seats on the floor tunnel, is equipped with a cable tension adjustment mechanism. The front tips of the cables are connected to the equalizer of the tension mechanism.

The parking brake does not require special care. During current repairs, check the degree of wear of its parts, make sure that the teeth of the sector and the pawl are in good condition. Replace excessively worn parts.

If a break in the sheaths or wires of the cables is detected, they must be replaced with new ones.

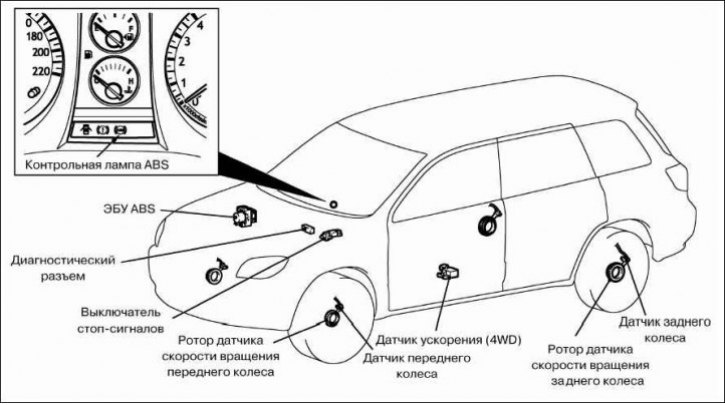

Anti-Lock Braking System (ABS)

Cars have anti-lock braking system (ABS) with electronic brake force distribution (EBD). ABS regulates the pressure in the brake mechanisms of all wheels during braking, preventing the wheels from blocking; reduces the braking distance during emergency braking while maintaining the stability and controllability of the car.

The anti-lock braking system includes the ABS electronic control unit, hydraulic unit, vacuum booster, brake master cylinder, wheel speed sensors and pipelines.

The electronic control unit and the ABS hydraulic unit, combined into a single module, are installed in the engine compartment under the vacuum brake booster and fixed to the front panel (for clarity, the photo was taken with the vacuum brake booster removed).

When the vehicle is braking, the ABS electronic control unit receives a signal from all wheel speed sensors and determines which wheel is currently on the verge of blocking. Based on the received signals, the electronic unit actuates the corresponding solenoid valve in the hydraulic unit to provide the required pressure in the pipeline of the corresponding wheel.

Self-diagnosis and emergency operation functions are built into the ABS electronic control unit. If the electronic control unit detects a malfunction in the system, the anti-lock brake system malfunction warning lamp lights up in the instrument cluster and the corresponding fault code is stored in the memory of the electronic control unit, which is read using a special diagnostic tool (scanner). In the event of a malfunction in the ABS, the braking system remains functional, but the wheels may lock when the vehicle is braked.

Anti-Lock Braking System (EBD)

Electronic brake force distribution (EBD) - This is the ABS subsystem, which serves to ensure effective adhesion of the rear wheels to the road surface.

With the EBD system, the braking force is maintained close to optimal and controlled electronically, eliminating the need for a pressure regulator.

The electronic brake force distribution system is controlled by the ABS electronic unit. When the vehicle is in motion, the brake force distribution system continuously detects the amount of slip on each wheel of the vehicle and regulates the front brake fluid pressure so that it exceeds the rear brake pressure. As a result, the rear wheels are prevented from locking up and the braking performance is improved.

In the event of a malfunction of the EBD system, the brake system warning light comes on in the instrument cluster (with red filter).