Removing

Note:

- Before starting to remove parts:

- A) Check the axial clearance of the rear wheel bearing,

- b) Check the torque of the rear wheel bearing.

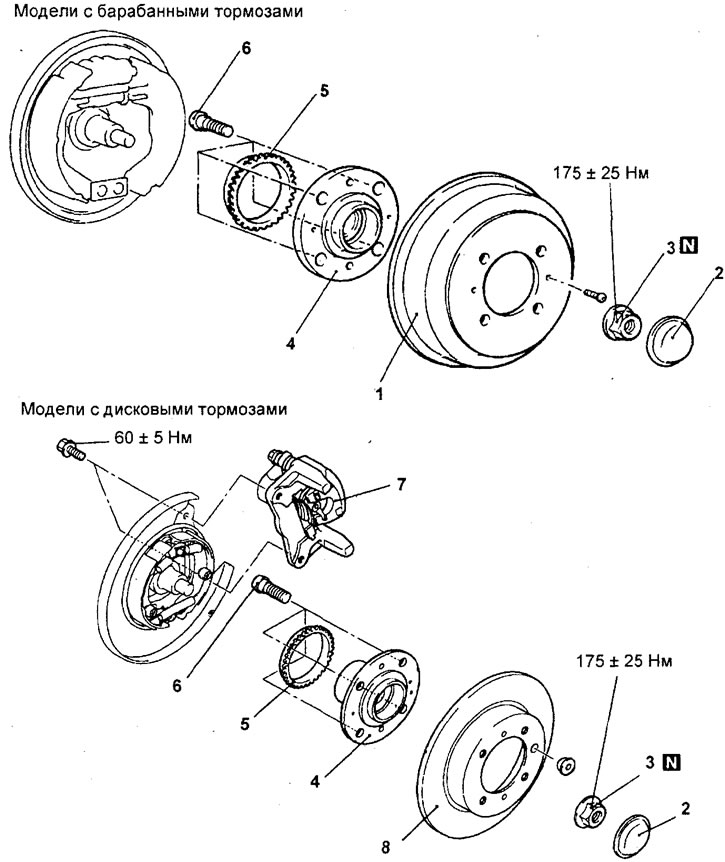

- Removal is carried out in the order of the numbers indicated in the figure "Rear wheel hub".

- Pay attention to the following operations when removing parts.

Rear wheel hub (2WD). 1 - brake drum, 2 - cap, 3 - nut, 4 - rear wheel hub, 5 - wheel speed sensor rotor, 6 - hub bolt, 7 - brake caliper, 8 - brake disc.

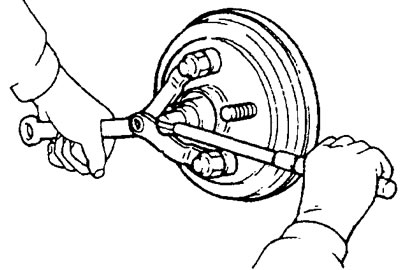

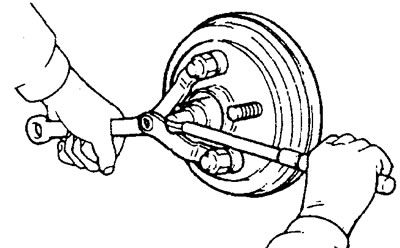

1. Loosen the rear wheel hub nut as shown.

Attention: before tightening the rear wheel hub nut, the rear wheel hub bearing must not be loaded by the weight of the vehicle.

Models with drum brakes.

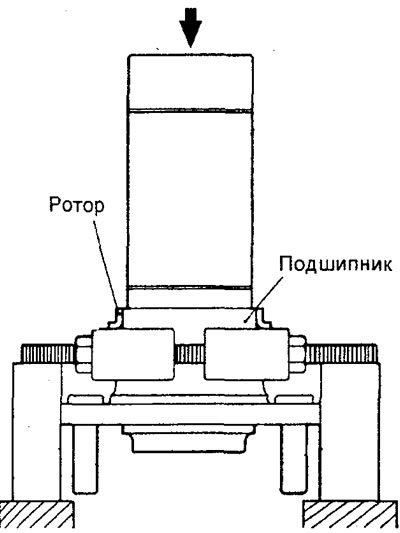

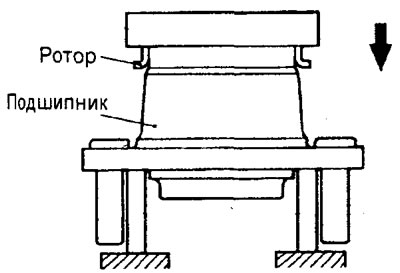

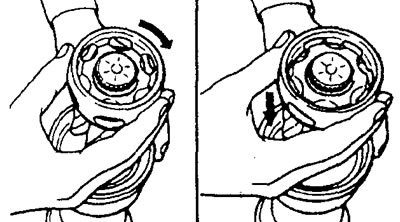

2. Using the special tool, remove the wheel speed sensor rotor as shown.

Installation

Note:

- - Installation is carried out in the reverse order of removal.

- − Pay attention to the following operations when installing parts.

1. Using the special tool, install the wheel speed sensor rotor as shown.

Note: Do not damage the wheel speed sensor.

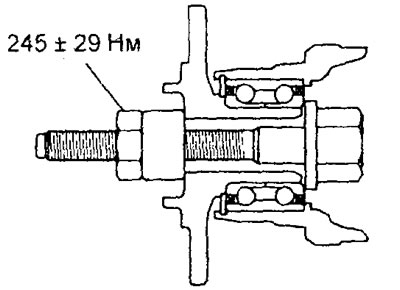

2. Tighten the rear wheel hub nut as shown.

Attention: before tightening the rear wheel hub nut, the rear wheel hub bearing must not be loaded by the weight of the vehicle.

Models with drum brakes.

Rear drive shafts

Removal and installation

Note:

- - Drain the brake fluid before removing parts.

- - Removal is carried out in the order of the numbers indicated in the figure "Rear drive shaft and rear wheel hub (4WD) ".

- - Installation is carried out in the reverse order of removal.

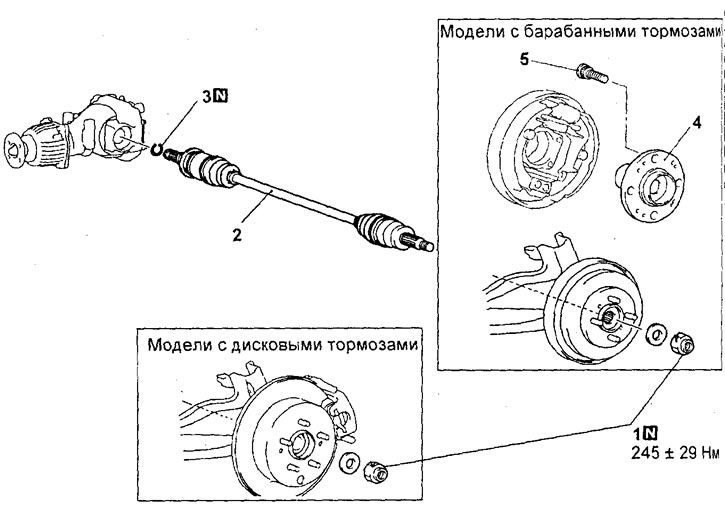

Rear drive shaft and rear wheel hub (4WD). 1 - nut, 2 - drive shaft, 3 - circlip, 4 - hub, 5 - hub bolt.

When removing parts, pay attention to the following operations.

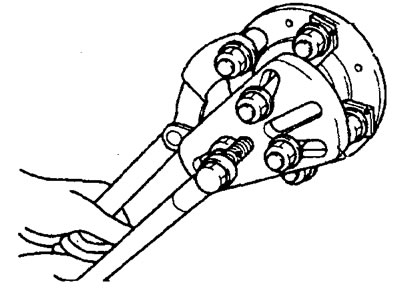

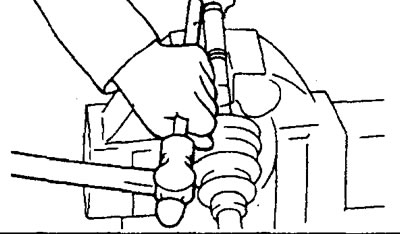

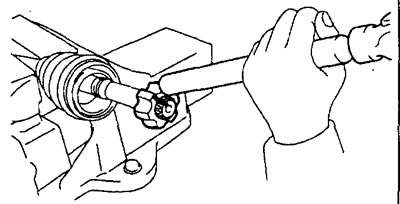

A) Using the special tool, disconnect the drive shaft from the rear wheel hub as shown.

Models with drum brakes.

Models with disc brakes.

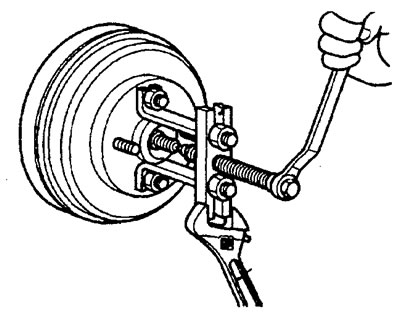

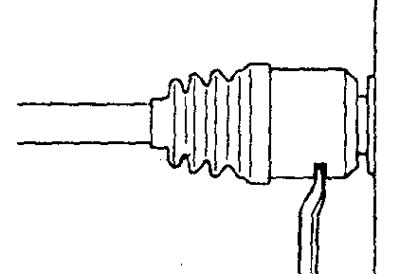

b) Using a pry bar, remove the drive shaft from the gearbox housing.

Note: do not damage the gearbox housing oil seal.

Caution: Be careful not to damage the wheel speed sensor rotor teeth. If the teeth of the rotor are chipped, this will lead to deformation of the rotor and, as a result, the impossibility of correctly determining the wheel speed and the malfunction of the ABS system.

Attention:

- - When loosening the drive shaft mounting nut, the hub bearing must not be loaded by the weight of the vehicle.

- - However, if you need to move the car to another location (the bearing must be loaded with the weight of the car), then temporarily tighten the nut using the special tool.

Disassembly

Note:

- - Removal is carried out in the order of the numbers indicated in the figure "Drive shaft disassembly".

- - Pay attention to the following operations when removing parts.

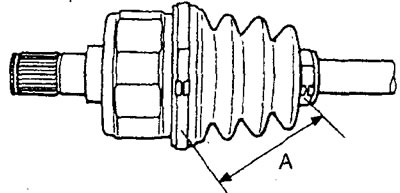

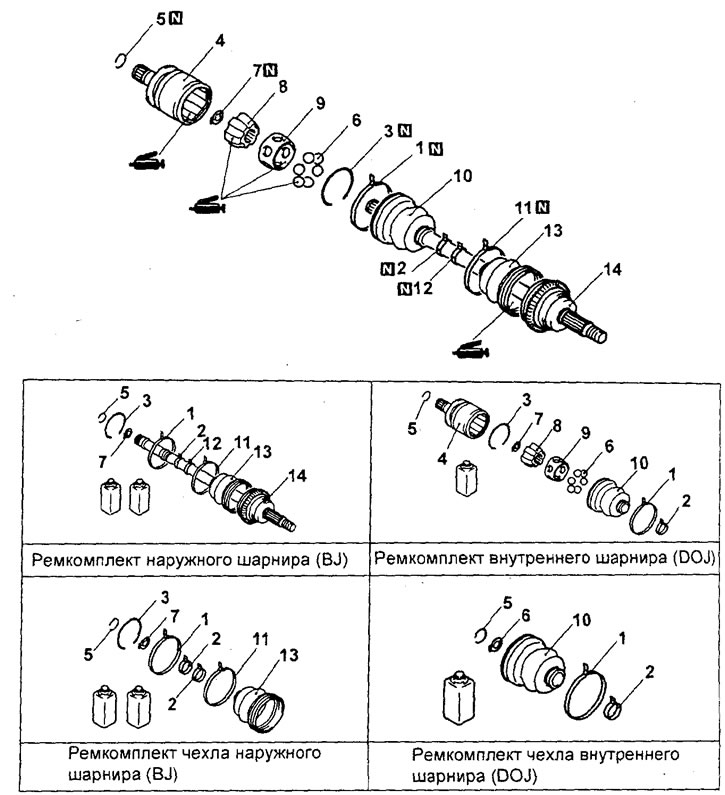

Disassembly of the drive shaft. 1 - clamp of the inner hinge boot, 2 - small clamp of the inner hinge boot, 3, 5, 7 - retaining ring, 4 - inner hinge cage, 6 - ball, 8 - inner hinge inner race, 9 - separator, 10 - inner hinge boot, 11 - large clamp of the outer hinge cover, 12 - small clamp of the outer hinge cover, 13 - outer hinge cover, 14 - outer hinge.

Note: the drive shaft is fitted with an external hinge type (BJ) and inner hinge type (DOJ).

Caution: Do not disassemble the outer driveshaft joint.

1. Remove the inner pivot retaining ring.

A) Remove grease from the inside of the inner joint race.

b) Remove the snap ring.

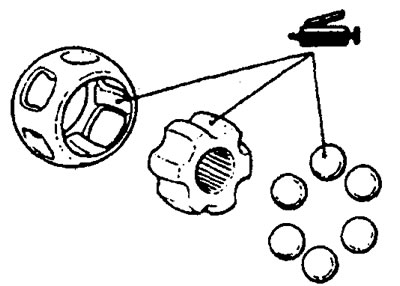

2. Remove the inner hinge.

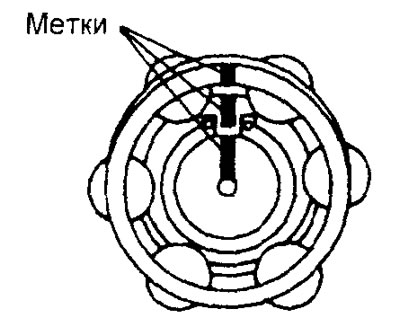

A) Put alignment marks on the drive shaft, inner race and cage.

Note: Do not mark with a sharp object.

b) Remove six balls.

V) Remove separator as shown.

V) Using the special tool, remove the retaining ring.

G) Using a copper rod and a hammer, remove the inner race.

3. Remove the outer hinge covers

A) Remove grease from drive shaft splines.

b) Remove the outer hinge cover.

Note: When reusing the outer pivot boot, wrap tape around the spline of the shaft to prevent damage to the boot.

Examination

1. Check up covers of hinges of a power shaft on absence of damages.

2. Check the driveshaft inner and outer joints for play and for excessive play.

3. Check the spline of the drive shaft (and hubs) for excessive wear or damage.

4. Check that there is no water or foreign matter on the outer hinge.

Assembly

Note:

- - Installation is carried out in the reverse order of removal.

- - When installing parts, pay attention to the following operations.

1. Install the outer hinge boot.

A) Wrap tape around the splined part of the wheel drive shaft.

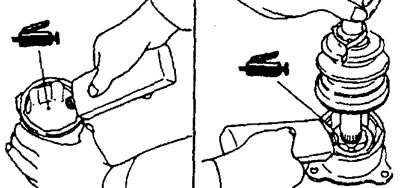

b) Fill the outer hinge boot with special grease.

Recommended Grease - Kit Grease

Quantity - 40±10 g

Note:

- - The grease from the repair kit should be divided equally to lubricate the hinge and lay it inside the boot.

- - Do not mix old and new grease or different types of grease.

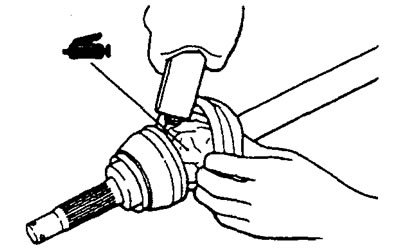

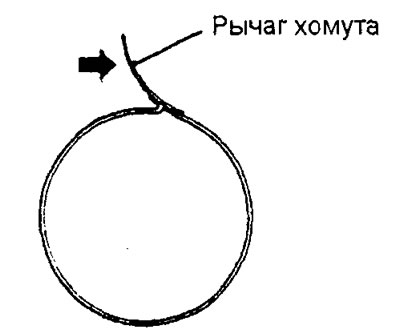

G) Tighten the outer hinge boot clamp.

Attention:

- - To ensure the correct amount of air in the outer joint, the installation of the boot must be carried out at zero angle of bending of the drive shaft.

- - Outer joint boot clamps and inner joint boot clamps are differentiated by identification numbers printed on the clamp arms. Be especially careful when installing the appropriate clamps.

Clamp identification numbers:

Sedan models:

big collar:

hinge type (BJ) — 20 - 128#BJ68L

hinge type (DOJ) — 20 - 66#BJ68

Small collar

20 - 138#BJ68

Station wagon models:

Large collar:

- hinge type (BJ) C868L

- hinge type (DOJ) 6668

- Small collar - D868

2. Install the inner hinge.

A) Using the special tool, install a new circlip.

b) Align the alignment marks and install the inner race on the drive shaft using a copper rod and a hammer.

Caution: Be careful not to damage the inner race.

V) Using the special tool, install a new circlip.

G) Align the alignment marks and install the separator and balls on the inner race.

Note: Apply lubricant to parts.

Attention:

- - A special grease is used to lubricate the drive shaft joints. Do not mix old and new grease or different types of grease.

- - If the inner joint assembly has been cleaned of grease, be especially careful to apply only the specified grease.

3. Install the inner joint race on the drive shaft.

A) Apply grease to the inner joint race and install the inner joint race to the drive shaft, applying grease to the joint.

The amount of lubricant - 45±10 g

4. Establish collars of covers of the internal hinge.

Install the clamps of the protective covers of the inner CV joint at an appropriate distance from each other (to provide the necessary amount of air inside the case), and then tighten the clamps securely.

Rated value (A) - 70 + Z mm