Removing

Note:

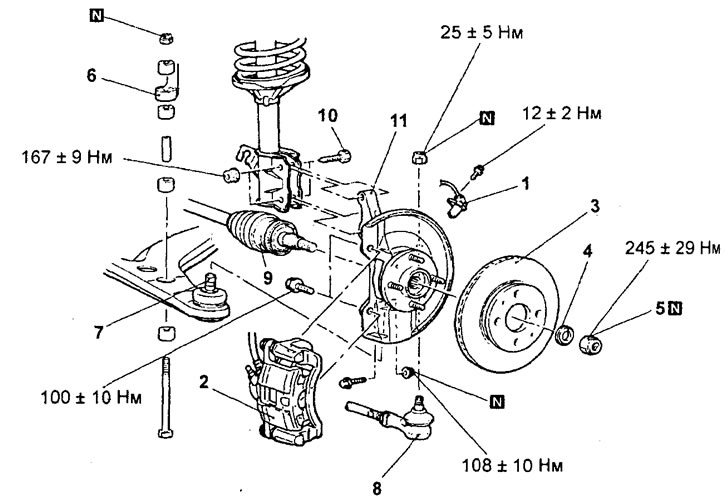

- - Removal of parts is carried out in the order of numbers indicated in the figure "Removing the front wheel hub".

- - Pay attention to the following operations when removing parts.

Removing the front wheel hub. 1 - front wheel speed sensor (models with ABS), 2 - brake caliper, 3 - brake disc, 4 - washer, 5 - drive shaft mounting nut, 6 - anti-roll bar connection, 7 - lower arm ball joint connection, 8 - tie rod end, 9 - drive shaft, 10 - front suspension strut mounting bolt, 11 - steering knuckle and front wheel hub.

Attention: (models with ABS) be careful not to damage the wheel speed sensor rotor.

1. Remove the brake caliper assembly.

Note: Temporarily suspend the brake caliper from the frame with a wire without disconnecting the brake hose.

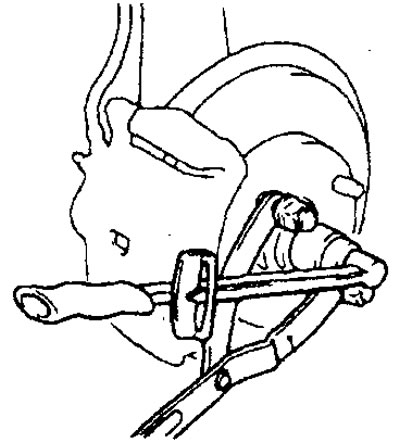

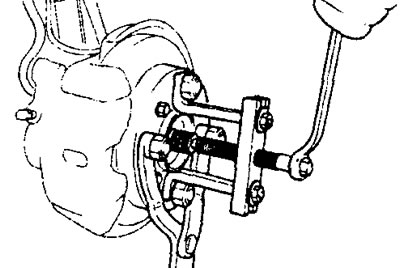

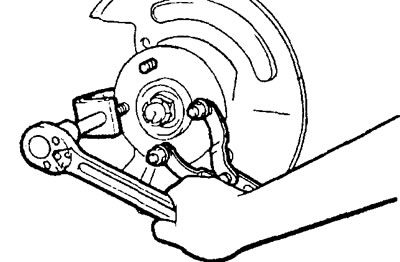

2. Loosen the drive shaft nut as shown.

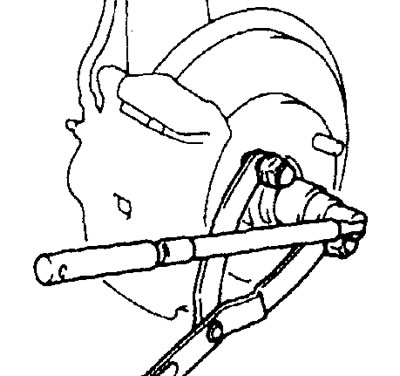

3. Disconnecting the ball joint of the lower suspension arm from the steering knuckle.

Attention:

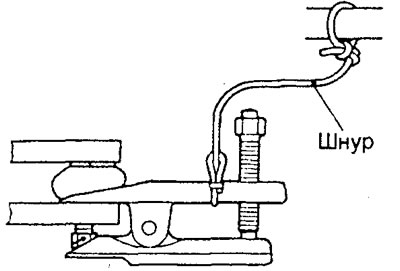

- - To prevent the puller from jumping off, you must first tie it with a cord to the suspension strut or other nearby part of the car.

- - Loosen the fastening nut on the ball joint pin at the steering knuckle without unscrewing it.

4. Remove the drive shaft.

Examination

1. Check the hub for cracks and signs of excessive wear on the splines.

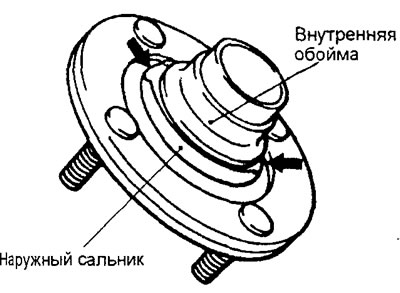

2. Check the oil seal for damage.

3. Check up a rotary fist on absence of cracks.

4. Check the hub bearing for damage.

Note: If there is play in the connection of the steering knuckle and the outer race of the bearing, or the hub and the inner race of the bearing, it is necessary to replace the bearing or damaged parts.

Disassembly

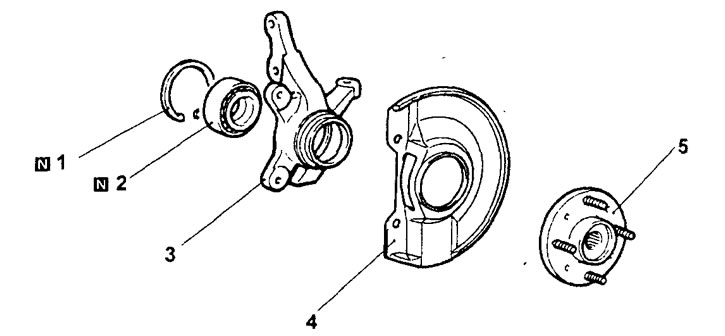

Note: the hub is disassembled in the order of the numbers shown in the figure "Disassembly and assembly of the front wheel hub". When removing parts, pay attention to the following operations.

Disassembly and assembly of the front wheel hub. 1 - retaining ring, 2 - hub bearing, 3 - knuckle, 4 - dust cover, 5 - hub.

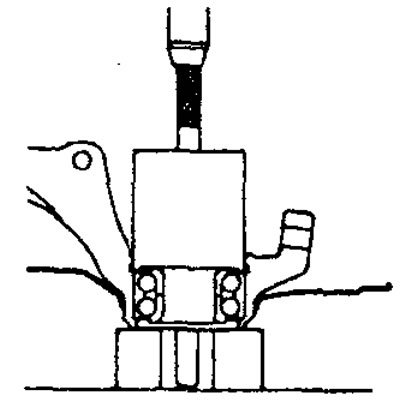

1. Remove the hub from the steering knuckle.

Attention: when removing the hub, replace the hub bearing with a new one.

2. Remove the hub bearing.

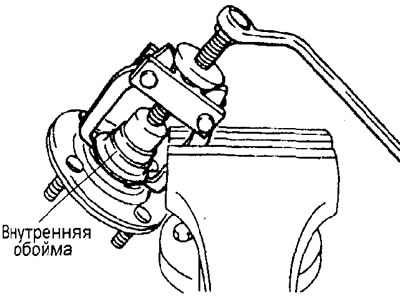

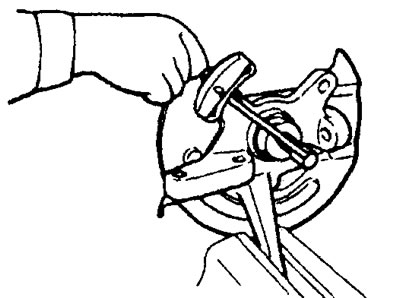

A) To capture the outer part of the inner race with a special tool, it is necessary to break the outer seal in two places, as shown in the figure.

b) Using the special tool, remove the bearing inner race from the hub (outer part).

Attention: when removing the inner race of the bearing, it is necessary to hold the hub to prevent it from falling.

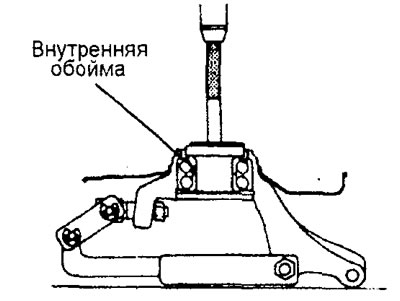

V) Install the outer part of the inner race removed from the hub as shown in the figure, then, using the special tool, remove the bearing.

Hub bolt replacement

1. Remove the brake caliper and brake disc.

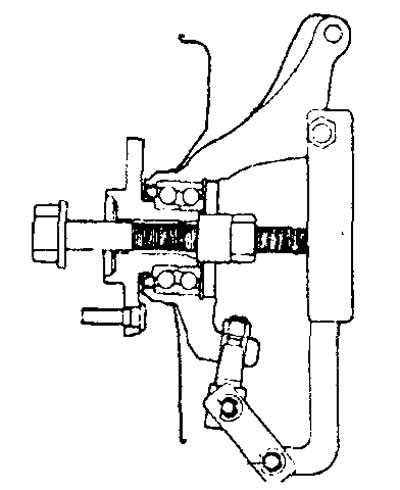

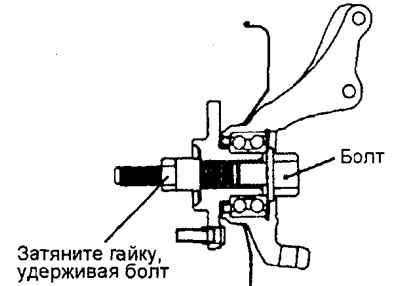

2. Using the special tool, remove the hub bolt.

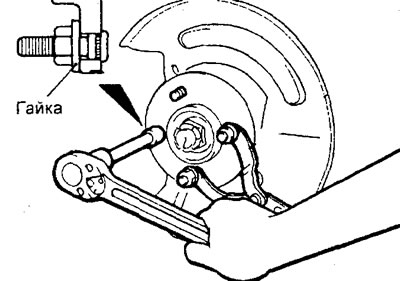

3. Using the hub bolt nut, install the new hub bolt as shown.

Examination

1. Clean the seating surfaces of the brake disc and wheel hub for fretting corrosion (corrosion attrition) and pollution.

2. Check up an internal surface of a rotary fist on absence of corrosion and cracks.

3. Check the bearing for a fault.

Assembly

1. Using a special tool, press the bearing into the steering knuckle.

Attention: the pressing force is applied to the outer race of the bearing.

2. Install the retaining ring in the steering knuckle.

3. Install the outer gland.

4. Establish a dustproof casing on a rotary fist.

5. Install the wheel hub on the steering knuckle.

6. Check up the moment of pulling off of the bearing of a nave.

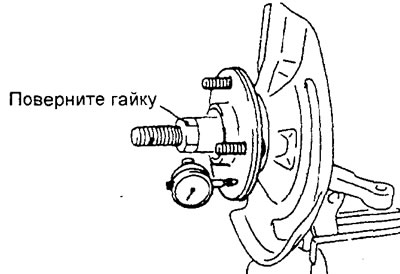

A) Using the special tool, install the hub into the steering knuckle.

b) Tighten the special tool nut.

Tightening torque - 245±29 N.m

V) Rotate the hub to properly install the bearing.

G) Using the special tool, measure the wheel bearing breakaway torque.

Limit value - 1.8 N.m or less

d) The pull-off torque of the hub bearing must be within the specified limits. In addition, the rotation of the bearing must be uniform, without jamming and vibration.

7. Checking the axial clearance of the hub bearing.

A) Measure the axial clearance of the wheel bearing.

Maximum allowable value - 0.05 mm

b) If, when tightening the fastening nut to a torque of 245±29 Nm, the breakaway torque and the axial clearance of the hub bearing are not within the specified limits, then this was probably the result of incorrect installation of the bearing, hub or improper assembly of these parts with the steering knuckle. In this case, replace the bearing, repeat the operation of installing the bearing into the hub.

8. Install the inner gland.

Installation

Note: Installation is in the reverse order of removal. Pay attention to the following operations when installing parts.

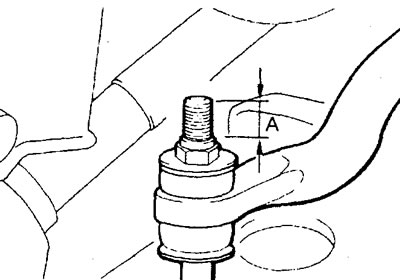

1. Installing the anti-roll bar nut.

Tighten the nut so that the length (A) the protruding part of the stabilizer mounting bolt corresponded to the nominal value.

Rated value (A) - 22±1.5 mm

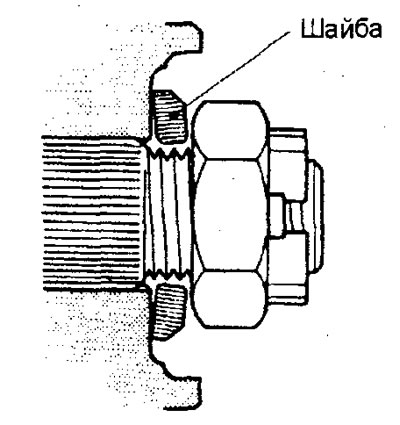

2. Establish nuts of fastening of a power shaft.

A) Make sure the drive shaft washer is installed correctly as shown.

b) Using the special tool, tighten the drive shaft mounting nut.

Tightening torque - 245±29 N

Attention: before tightening the drive shaft mounting nut, the front wheel hub bearing must not be loaded with the weight of the vehicle.