Removing

Note:

- - Parts are removed in the order of the numbers indicated in the corresponding figure "Removal and installation of a forward power shaft".

- - (4WD Models) Drain the gearbox oil before removing.

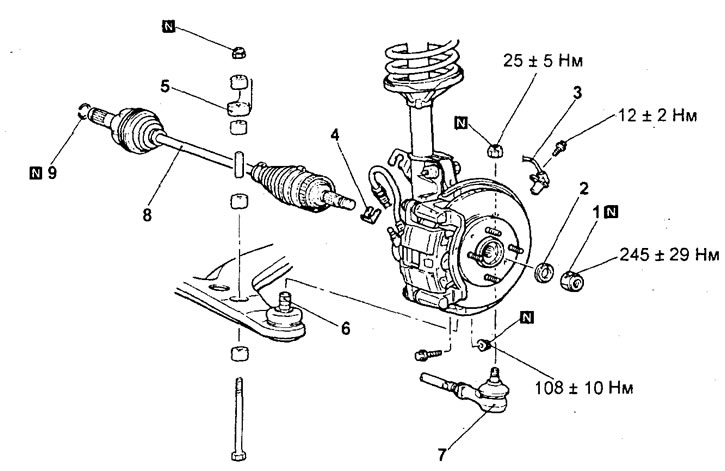

Removal and installation of a forward power shaft (2WD models). 1 - drive shaft mounting nut, 2 - washer, 3 - wheel speed sensor, 4 - retainer, 5 - anti-roll bar connection, 6 - lower arm ball joint connection, 7 - tie rod end, 8 - drive shaft, 9 - retaining ring.

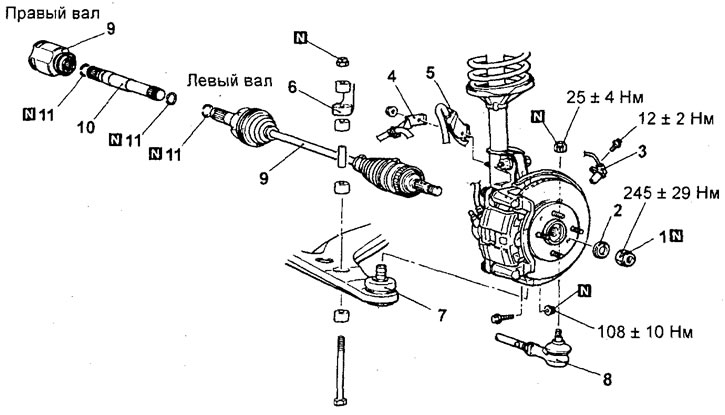

Removal and installation of a forward power shaft (4WD models). 1 - drive shaft mounting nut, 2 - washer, 3 - wheel speed sensor, 4 - wheel speed sensor wire mounting bracket, 5 - brake hose mounting bracket, 6 - anti-roll bar connection, 7 - lower arm ball joint connection, 8 - tie rod end, 9 - drive shaft, 10 - inner shaft, 11 - retaining ring.

When removing parts, pay attention to the following operations.

1. Turn away nuts of fastening of a power shaft.

Attention: when loosening the drive shaft mounting nut, the hub bearing must not be loaded with the weight of the vehicle.

2. Disconnect the ball joint of the lower suspension arm from the steering knuckle.

Attention:

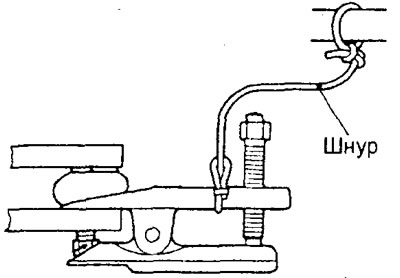

- To prevent the puller from jumping off, you must first tie it with a cord to the suspension strut or other nearby part of the car.

- Loosen the fastening nut on the ball joint pin at the steering knuckle without unscrewing the nut completely.

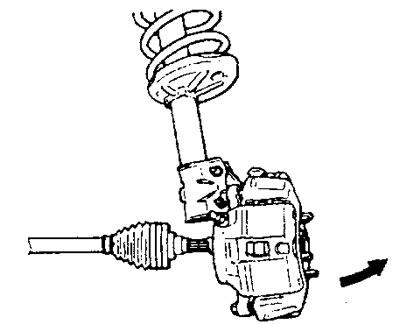

3. Remove the drive shaft.

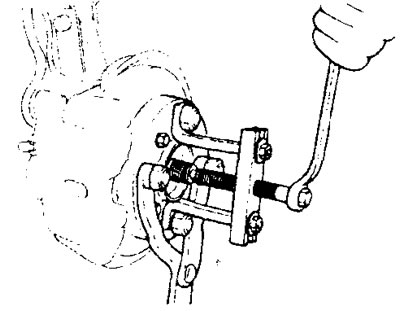

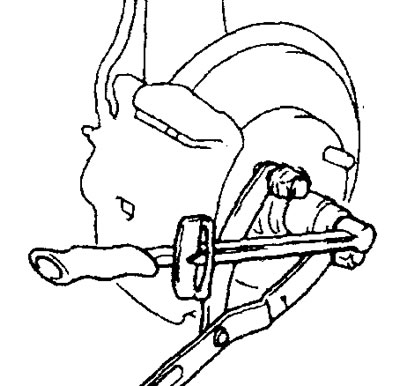

A) Using the special tool, disconnect the drive shaft from the hub.

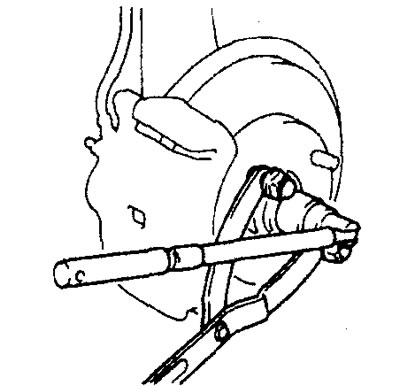

b) Pull the hub to the side as shown in the figure and disconnect the drive shaft.

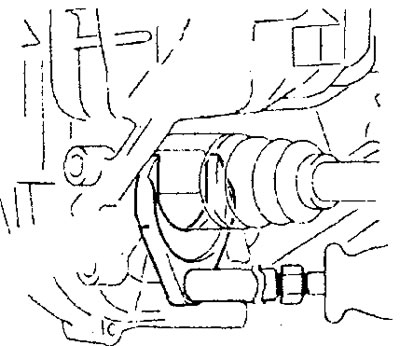

V) Install the special tool between the gearbox housing and the drive shaft, and then disconnect the wheel drive shaft from the gearbox.

Note:

- Always use a special tool; it is forbidden to pull out the wheel drive shaft without a special tool, as such an operation will damage the internal joint of the drive shaft.

- To avoid damage to the oil seal, do not install the special tool too deep.

- When loosening the drive shaft mounting nut, the hub bearing must not be loaded with the weight of the vehicle. However, if you need to move the car to another location (the bearing must be loaded with the weight of the car), then temporarily tighten the nut.

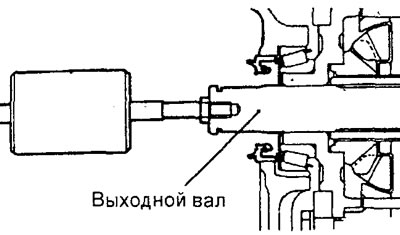

4. (4WD Models) Using the special tool, remove the inner shaft from the gearbox.

Note: do not damage the seal.

Examination

1. Check the driveshaft inner joint boot for damage.

2. Check ball joints for wear and play.

3. Check the spline of the drive shaft (and hubs) for signs of excessive wear or damage.

Installation

Note:

- - Installation is carried out in the reverse order of removal. Pay attention to the following operations when installing parts.

- - (4WD Models) After installation, fill the gearbox with oil.

1. Install the drive shaft.

Attention: when installing the drive shaft, do not damage the oil seal.

2. Establish nuts of fastening of the stabilizer of cross-section stability.

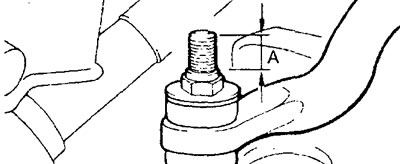

Tighten the nut so that the length (A) the protruding part of the stabilizer mounting bolt corresponded to the nominal value.

Rated value (A) — 22±1.5 mm

3. Install the drive shaft mounting nut.

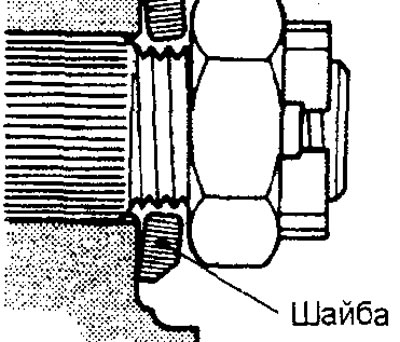

A) Make sure the drive shaft washer is installed correctly as shown.

b) Using the special tool, tighten the drive shaft mounting nut.

Torque - 245 + 29 Nm

Attention: before tightening the drive shaft mounting nut, the front wheel hub bearing must not be loaded with the weight of the vehicle.

V) If the mounting holes for the cotter pin do not match, then additionally tighten the nut with a tightening torque not exceeding 260 Nm.

G) After matching the mounting holes, install the cotter pin in place and part its antennae.