Note:

- Procedures for checking the throttle position sensor and crankshaft position sensor are given in chapter "fuel injection system".

- The procedure for checking the vehicle speed sensor is given in the chapter "Body electrical equipment".

- Double Pressure Switch or Triple Pressure Switch Test Procedure (A/C compressor load signal) given in chapter "Heating, air conditioning and ventilation system".

- The procedure for checking the brake light switch is given in chapter "Brake system".

- For a detailed procedure for checking the engine start inhibit switch, see "Checking and adjusting the engine start inhibit switch and automatic transmission control cable".

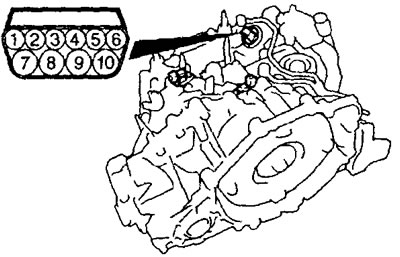

1. Checking the start inhibit switch.

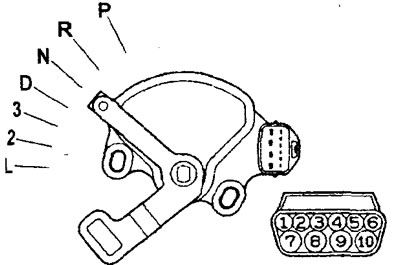

Check the start inhibit switch circuit according to the table below.

Table. Checking the switch.

| Selector position | Circuit closed between pins |

| R | 3-8and 9-10 |

| R | 7-8 |

| N | 4-8and9-10 |

| D | 1 -8 |

| 1 | 5-8 |

| 2 | 2-8 |

| 3 | 6-8 |

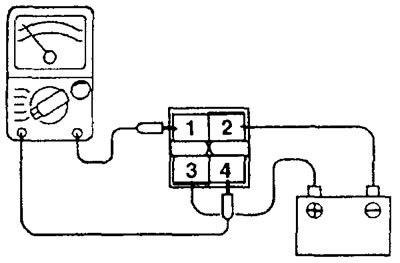

2. Checking the automatic transmission control relay.

A) Remove the relay.

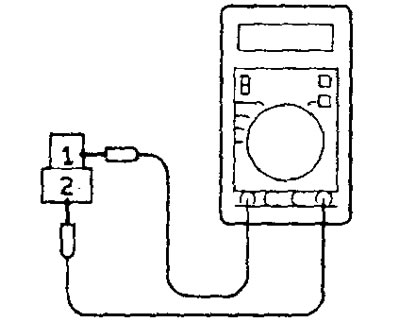

b) Connect the voltmeter and power supply as shown.

V) When connecting and disconnecting the power supply wire, check the continuity between the terminals "1" And "4" connector.

| Power supply | Conductivity |

| Connected | Eat |

| Disconnected | No |

G) Replace relay if necessary.

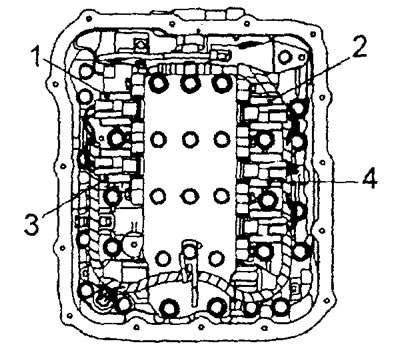

3. Checking the solenoid valves.

A) Disconnect the solenoid valve block connector.

b) Bring the temperature of the working fluid to 20°C and measure the resistance at the terminals of the connector of the solenoid valve block (see table "Checking the solenoid valves").

V) If the values obtained do not correspond to the specifications, check the power supply and ground circuit and repair any problems.

G) If these steps do not correct the problem, check each solenoid valve.

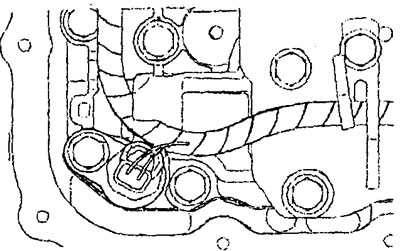

- Remove the cover of the solenoid valve block.

Solenoid valve block. 1 - overdrive clutch control solenoid valve, 2 - underdrive clutch control solenoid valve, 3 - first gear and reverse gear control solenoid valve, 4 - second gear brake solenoid valve.

- Measure the resistance at the connector pins of each solenoid valve.

Rated resistance (at 20°С) - 2.7 - 3.4 ohms

- If the measured resistance does not correspond to the nominal resistance, check the wiring and valve o-rings, then repeat the test.

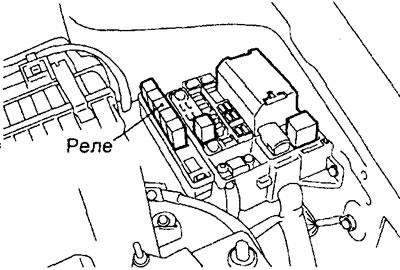

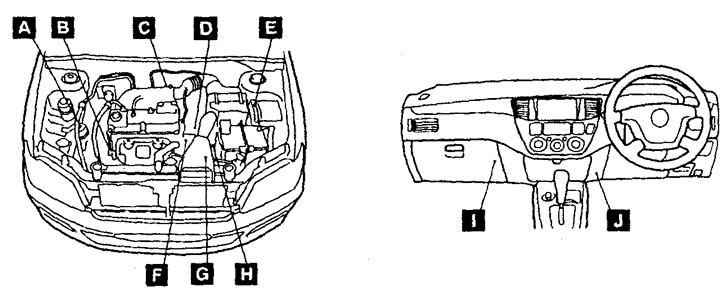

The location of the components of the automatic transmission control system. A - double switch for refrigerant pressure; B - crankshaft position sensor; C - throttle position sensor with built-in sensor-switch for the fully closed throttle position, D - automatic transmission output shaft speed sensor (pulse generator "IN"); E - automatic transmission control relay; F - frequency sensor by rotation of the input shaft of the automatic transmission (pulse generator "A"); G - start inhibit switch; H - automatic transmission fluid temperature sensor and automatic transmission control solenoid valves; I - electronic engine and automatic transmission control unit, J - diagnostic connector.

Table. Checking the solenoid valves.

| Pin numbers | valve name | Rated resistance |

| 6-10 | 1st and reverse brake control solenoid valve | 2.7-3.4 ohm |

| 4-9 | Second gear brake solenoid valve | 2.7-3.4 ohm |

| 3-9 | Underdrive Clutch Control Solenoid Valve | 27-3.4 ohm |

| 5-9 | Overdrive Clutch Control Solenoid Valve | 2.7 - 3.4 ohm |

- If the measured resistance is still not within specification, replace the faulty solenoid valve.

Note: If necessary, replace the solenoid valve block assembly.

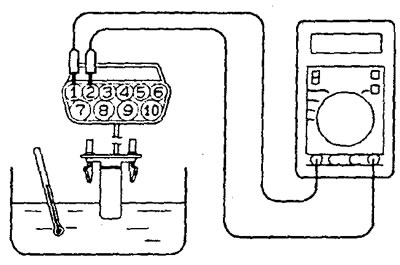

4. Checking the automatic transmission fluid temperature sensor.

A) Remove the sensor.

b) Using an ohmmeter, measure the resistance between the leads "1" And "2" sensor connector at different temperatures of the working fluid.

Table. Rated values.

| Temperature | Resistance |

| 0°C | 16.70 - 20.50 kOhm |

| 20°C | 7.30 - 8.90 kOhm |

| 40°C | 3.40 - 4.20 kOhm |

| 60°С | 1.90-2.20 kOhm |

| 80°С | 1.00-1.20 kΩ |

| 100°C | 0.57 - 0.69 kOhm |

Note: when the working fluid is heated to a temperature of 125°C, the range indicator "N" will start flashing, but when the temperature drops to 115°C, the flashing will stop.

V) If a malfunction is detected in the fluid temperature sensor, replace the sensor.

Adjustment of the automatic transmission control cable and start inhibit switch

1. Checking the condition of the circuit at the terminals of the engine start inhibit switch connector.

A) Disconnect the start inhibit switch connector.

b) Check the condition of the circuit between the terminals of the connector at various positions of the switch according to the table below.

Table. Checking the switch.

2. Check the compliance of the gears to be engaged with each position of the automatic transmission selector and the correct operation of the gearbox in each of the ranges. Make adjustments if necessary.

3. Set the selector to position "N" (neutral position).

4. Loosen the adjusting nut securing the automatic transmission control cable to the manual control lever to loosen the cable tension.

5. Place the hand lever in neutral position "N".

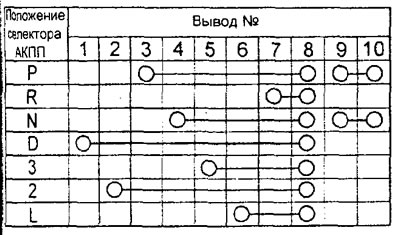

6. Loosen the bolts securing the start inhibit switch and rotate the switch housing so that the hole in the housing flange aligns with the hole in the manual control lever youth (section A-A in the figure).

Adjustment of the automatic transmission control cable and start inhibit switch. 1 - bolts, 2 - start inhibit switch lever, 3 - start inhibit switch.

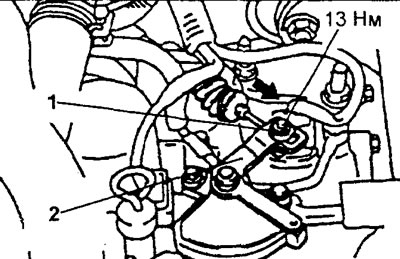

7. Tighten the start inhibit switch mounting bolts.

Note: Do not change the position of the start inhibit switch.

Tightening torque - 10 - 12 Nm

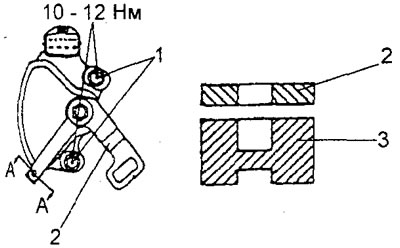

8. Lightly tighten the cable connecting the automatic transmission selector to the control valve block in the direction of the arrow and then tighten the adjusting nut.

Adjustment of the automatic transmission control cable and start inhibit switch (continuation). 1 - adjusting nut, 2 - start inhibit switch lever.

Tightening torque - 10 - 14 Nm

9. Make sure that the automatic transmission selector is in position "N" (neutral position).

10. Check the correspondence of the included gears to each position of the automatic transmission selector, and make sure that the automatic transmission works correctly in each of the ranges.

Checking the operation of the automatic transmission selector

1. Raise the parking brake lever.

2. Move the variator selector from position to each position and check that the selector shifts are smooth and crisp.

3. Check that the engine starts when the selector is in the "R" or "N", and that the engine cannot be started when the selector is in other positions.

4. Start the engine, release the parking brake lever and check the operation of the transmission control mechanism.

When moving the selector from position "N" V "D", "3", "2" or "L" the car must move forward, and when the selector is moved to the "R" the vehicle must move in reverse).

5. Stop the engine.

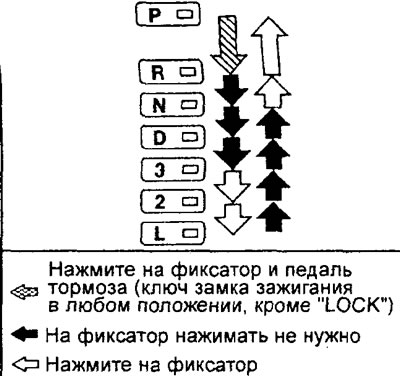

6. Turn the ignition key to position "ON", move the automatic transmission selector from the position "R" into position "R" and make sure that when the automatic transmission selector is in position "R", the reversing lights come on and the buzzer sounds. Note: the ignition lock and selector interlock systems do not allow the inclusion of unacceptable modes of operation of the variator, if switching can lead to breakage, therefore, to move the selector from the position "R" to other positions, you need to press the brake pedal and turn the key in the ignition switch to any position, except "LOCK".

Checking and adjusting the ignition lock mechanism

1. Checking the operation of the ignition lock system.

A) Check that if, with the brake pedal depressed, the ignition key is in the "LOCK" or extracted, then the selector cannot be moved from the position "R" to any other without pressing the selector latch.

b) Check that if the ignition key is in any position other than "LOCK", then the selector can be translated from the position "R" to any other when the brake pedal is depressed and the release button is pressed. Check up smoothness of movement of the selector.

V) Check that it is not possible to turn the ignition key to the "LOCK" in any position of the selector, except "R" (brake pedal released). Check that the ignition key can be smoothly moved to the position "LOCK", when the selector is in position "R" (brake pedal released).

G) If the operation of the system differs from the above, adjust the ignition lock cable.

2. Adjustment of a cable of blocking of the lock of ignition.

A) Remove the bottom of the center console (see chapter "Body").

b) Set the selector to position "R" and the ignition key to position "LOCK".

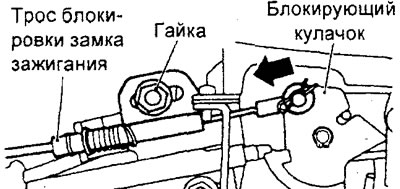

V) Loosen the nut securing the ignition lock cable.

G) Slightly pull the locking cam in the direction "A", indicated by the arrow in the figure and, holding it in this position, tighten the nut securing the ignition lock cable.

d) Install the bottom of the center console (see chapter "Body").

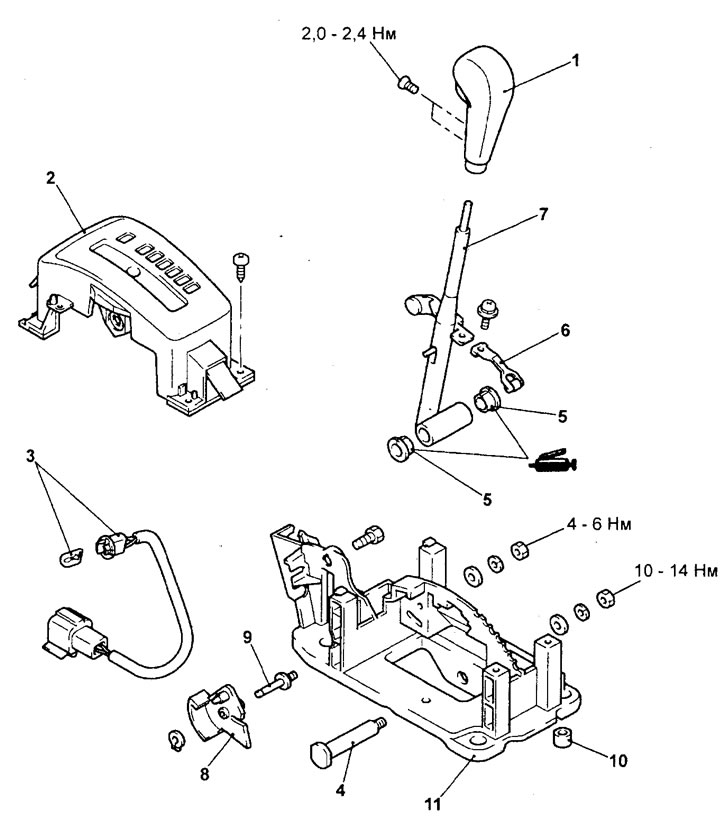

Automatic transmission selector. 1 - selector knob, 2 - selector position indicator panel, 3 - selector position indicator, 4 - bolt, 5 - bushing, 6 - detent spring, 7 - selector lever, 8 - blocking cam, 9 - pin, 10 - bushing, 11 - selector bracket.

Checking and adjusting the automatic transmission selector lock system

1. Checking the operation of the selector lock system.

A) Check that if, with the brake pedal depressed, the ignition key is in the "ACC", then the selector cannot be translated from the position "R" to any other without pressing the selector latch.

b) Check that if, with the brake pedal depressed, the ignition key is in the "ACC", then the selector can be translated from the position "R" to any other by pressing the selector latch.

V) Check that if, with the brake pedal released and the release button pressed, the ignition key is in the "ACC", then the sele torus can be translated from the position» "R" into position "R".

G) If the functioning of the systems differs from the above, and adjust the selector lock cable.

2. Adjustment of the automatic transmission selector lock cable.

A) Remove the bottom of the center console (see chapter "Body").

b) Set the selector to position "R"

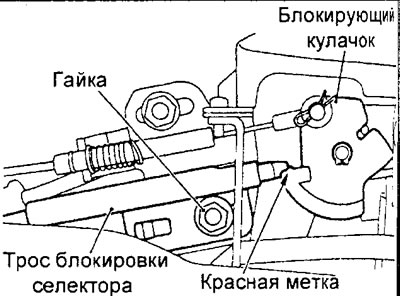

V) Loosen the selector lock cable nut.

G) Adjust the position of the cable so that its edge is located in the middle of the red mark of the locking cam, as shown in the figure.

d) Tighten the cable nut.

e) Install the bottom of the center console (see chapter "Body").

e) Install the bottom of the center console (see chapter "Body").

4. Lightly pull the cable in the direction "A", indicated by the arrow in the figure and, holding it in this position, tighten the nut securing the automatic transmission control cable.

Tightening torque - 12±2 Nm

5. Install the battery bracket and battery.