Removing

− Before starting to remove parts, carry out the following operations:

- A) Remove the bottom protective casing of the power unit.

- b) Drain the transmission fluid (see chapter "Maintenance and general inspection and adjustment procedures").

- V) Drain the coolant (see chapter "Maintenance and general inspection and adjustment procedures").

- G) Remove the engine cover (see chapter "Engine - mechanical part").

- d) Remove the battery and battery bracket.

- e) Remove elements of system of release of the fulfilled gases (see chapter "Intake and exhaust systems").

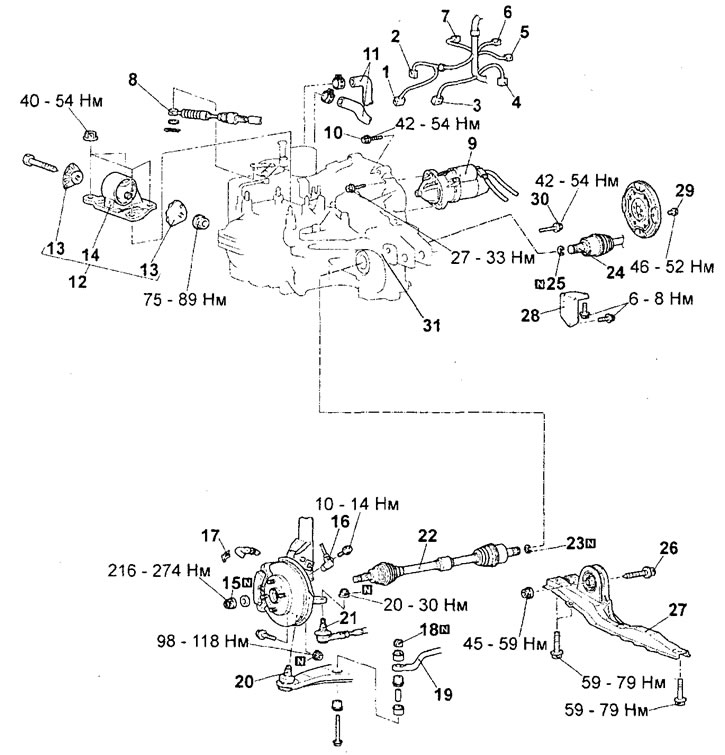

- Parts are removed in the order of the numbers shown in the figure "Removing the variator assembly".

− To remove some elements or separate them from other parts, refer to the relevant chapters:

- starter - see chapter "Engine start system";

- drive shafts - see chapter "Drive shafts and axle shafts";

- front suspension lower arm and anti-roll bar - see chapter "Suspension";

- wheel speed sensor - see chapter "Brake system".

Removing the gearbox assembly. 1 - connector for CVT control solenoid valves, 2 - connector for start inhibit switch, 3 - connector for automatic transmission input shaft speed sensor, 4 - connector for automatic transmission output shaft speed sensor, 5 - connector for knock sensor, 6 - connector for coolant temperature sensor, 7 - connector for the working fluid temperature indicator, 8 - automatic transmission control cable connection (from the automatic transmission), 9 - starter, 10 - automatic transmission bracket bolt, 11 - coolant hoses, 12 - automatic transmission support, 13 - support stopper, 14 - support, 15 - drive shaft locknut, 16 - wheel speed sensor, 17 - brake hose retainer, 18 - stabilizer mounting nut, 19 - anti-roll bar, 20 - ball joint of the lower arm of the front suspension, 21 - tie rod end, 22 - left drive shaft, 23 - circlip, 24 - right drive shaft, 25 - circlip, 26 - cross beam bolt, 27 - cross beam, 28 - trim, 29 - bolt, 30 - mounting bolt, 31 - gearbox assembly.

Note: the nut securing the gearbox to the transverse beam should first be tightened only in advance, and the final tightening to the specified torque should be made after the gearbox is completely lowered onto the supports.

Installation

− Installation of parts is carried out in the reverse order of removal.

− When installing parts, pay attention to the following operations:

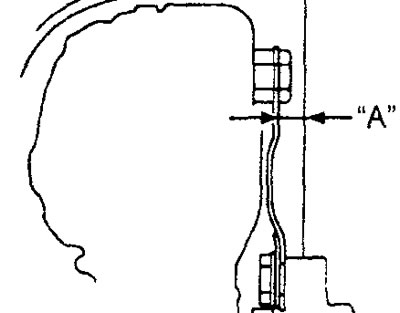

1. Installing the gearbox assembly. Move the torque converter fully towards the transmission so that "A", shown in the figure corresponds to the rated value, then install the variator assembly on the engine.

Value "A" - 12.2 mm

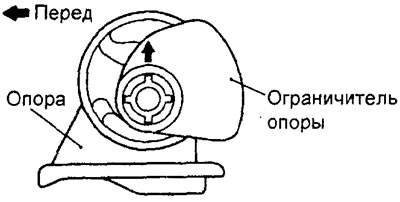

2. Gearbox support limiter.

Install the gearbox support limiter so that the arrow on the limiter is located as shown in the figure.

− After completing the installation of the parts, perform the following operations:

A) Establish elements of system of release of the fulfilled gases (see chapter "Intake and exhaust systems").

b) Install the battery and battery bracket.

V) Install the engine cover (see chapter "Engine - mechanical part").

G) Fill with coolant (see chapter "Maintenance and general inspection and adjustment procedures").

d) Pour the working fluid into the automatic transmission (see chapter "Maintenance and general inspection and adjustment procedures").

e) Install the lower protective casing of the power unit.

and) (4WD Models) Install transfer case (see section "Transfer box assy").

h) Perform the following checks and adjustments (see section "Checking the automatic transmission control system"):

- check and, if necessary, adjust the engine start inhibit switch and the automatic transmission control cable;

- check the operation of the automatic transmission selector;

- check and, if necessary, adjust the ignition lock mechanism;

- check and, if necessary, adjust the automatic transmission selector locking system;

- if necessary, adjust the automatic transmission control cable.