Troubleshooting automatic transmission

Note:

- Automatic transmission malfunctions can be caused by improper maintenance, improper adjustment or malfunction of the electronic control system of the automatic transmission, mechanical malfunction of the transmission, malfunction of the automatic transmission hydraulic control system, insufficient engine power, or a combination of these malfunctions. Therefore, before starting the test, it is necessary to determine the area of \u200b\u200bthe malfunction (engine, control system or gearbox).

- Troubleshooting should start with the simplest operations and proceed in order of increasing complexity.

1. Check for signs of automatic transmission malfunctions and the conditions under which they occur.

2. Read diagnostic trouble codes. Write down the trouble codes, and then clear the codes from the memory of the automatic transmission electronic control unit.

3. Perform basic checks and adjustments (checking tire pressure, checking the level and condition of the working fluid (ATF) in automatic transmission, checking the automatic transmission control mechanism, etc.), for which the deviation from the norm can be easily determined.

Note: analysis of the results of checking the level of the working fluid:

- If the fluid level in the automatic transmission is below normal, then the oil pump will capture the fluid along with air, which will lead to various malfunctions. Air bubbles that have entered the hydraulic system of the automatic transmission cause foaming of the working fluid. This will cause unstable pressure in the hydraulic system, which in turn will lead to a delay when shifting gears (late gear shifting) and slipping clutches or brakes, etc.

- − If the working fluid level is higher than normal, then due to the rotation of the gears of the planetary mechanisms, abundant foaming of the working fluid will occur, which will lead to the same consequences as in the case of a low working fluid level, and will cause premature deterioration of the automatic transmission fluid.

- In both cases, air bubbles cause overheating, oxidation of the working fluid and varnish deposits that damage valves, couplings and actuators. Foaming also causes fluid to escape through the transmission breather, which is mistaken for leaks.

4. Carry out a road test to determine if further transmission diagnostics are needed.

A) Check for proper gear shifting. Check the electrical part of the control system if the gear shift is correct.

b) Make sure that the fault only applies to the gearbox. If noise or vibration is present, possible sources may be the compressor, engine, cardan shaft (4WD models), etc.

5. Read diagnostic trouble codes.

A) If fault codes are displayed when there is a symptom of a malfunction, then refer to subsection "Diagnostic codes and probable causes of malfunctions".

6) If there is a symptom (no fault codes) or in the absence of a symptom of a malfunction, it is necessary to check for the presence of fault codes read before road testing. If fault codes are displayed, then refer to subsection "Diagnostic codes and probable causes of malfunctions", if fault codes are not displayed, then refer to subsection "Troubleshooting by their symptoms".

6. If a possible cause is a malfunction in the automatic transmission electronic control system, then use a tester or oscilloscope to check the input and output signals of the automatic transmission electronic control unit.

A) If there are incorrect input and output signals of the automatic transmission control unit, then check the wiring according to the appropriate wiring diagram.

b) If no fault is found when checking the wiring, then check the individual components of the system.

7. If the signals of the electronic control system are normal or if a possible cause is a malfunction in the automatic transmission control hydraulic system, then check the pressure in the automatic transmission control hydraulic system (hydraulic test). If the condition of the hydraulic system differs from normal, then perform the appropriate checks and adjustments of subsection "Troubleshooting by pressure values in the automatic transmission hydraulic control system".

8. If the pressure in the automatic transmission control hydraulic system is correct or if a malfunction in the main automatic transmission system is a possible cause (mechanical part), then check the engine and torque converter with the vehicle fully braked (stall test), identify the defective part and make the necessary overhaul.

9. After repair is complete, perform a road test to verify that the problem has been corrected.

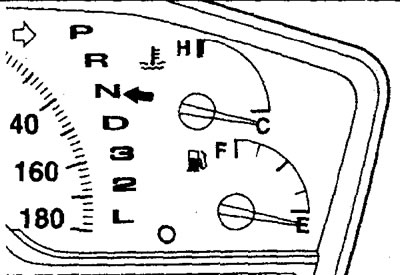

Range indicator "N"

1. If the range indicator "N" flashes at a frequency of 1 time per second (1 Hz), it means that a malfunction has been detected by the self-diagnosis system.

2. In this case, you need to check the diagnostic trouble codes.

Attention: if the range indicator "N" flashes at a frequency of 2 times per second (2 Hz), then this indicates an increased temperature of the working fluid in the automatic transmission, so stop the car in a safe place and let the engine idle until the indicator goes out.

Reading Diagnostic Trouble Codes

Note: Use the table to identify fault codes "Codes of malfunctions of the automatic transmission control system".

1. Prepare the vehicle for inspection as follows.

A) Make sure the battery is in good condition, as fault detection is not possible when the battery voltage is low.

b) Turn off all additional equipment.

V) Set the automatic transmission selector to position "N".

Attention: do not disconnect the battery until the diagnostic results are completely read, as the fault code will be deleted from the memory of the electronic control unit when the battery or the connector of the electronic control unit is disconnected.

2. Turn the ignition key to the position "OFF" (OFF).

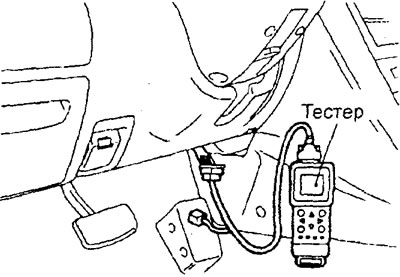

3. When checking with a tester:

A) Connect the tester to the diagnostic connector under the instrument panel.

Attention: when connecting or disconnecting the tester "ignition" should be off (ignition key in position "OFF" (OFF)).

b) Turn on the ignition and select the test mode of the automatic transmission control system on the tester.

4. Reading codes without using a tester (using the range indicator "N").

A) To connect with "weight" use the special tool.

b) Turn the ignition on and read the trouble codes while observing the number of blinks of the range indicator "N" on the instrument cluster.

Note:

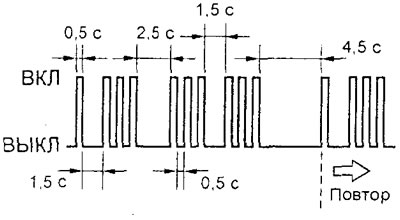

- The fault code consists of two digits, the first digit is determined by the initial series of flashes, then after a pause of 2 seconds, a second series of flashes follows, which corresponds to the second digit of the code.

- If there are two or more fault codes, the smallest code will be displayed first, and then the rest in ascending order. There will be a 3 second pause between codes.

- The figure shows an example of the output codes "13" And "33".

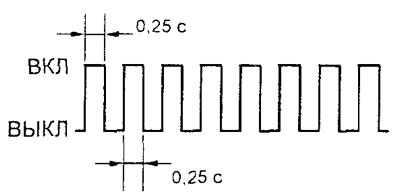

V) If there is no fault, the indicator will flash at intervals of 0.5 seconds (normal state code).

5. After completing the test, turn the ignition key to the position "OFF" (OFF) and then disconnect the tester or special tools from the diagnostic connector.

Clearing Diagnostic Trouble Codes

1. Turn the ignition key to position "OFF" (OFF).

2. If a tester is used, then connect it to the diagnostic socket and erase the codes.

3. If the tester is not being used, disconnect the cable from the negative battery terminal for 10 seconds or more.

Attention: after disconnecting the wire from the negative terminal of the battery, the contents of the memory of electronic control units of other systems will be lost.

4. After the engine has warmed up, let it idle for at least 15 minutes.

Troubleshooting by their symptoms

Attention:

- - Automatic transmission malfunctions can be caused by a malfunction of the engine systems, improper adjustment or internal malfunction of the electronic or hydraulic control systems of the transmission, mechanical failure of the transmission. Therefore, ALWAYS start the diagnosis by checking the level and condition of the fluid in the automatic transmission and adjusting the control cables.

- - Checking engine systems means checking the engine management system, ignition system, fuel system, as well as the engine itself.

- - Checking the parts of the gearbox housing means checking the clutches, brakes, and internal gears of the gearbox.

- - When checking the control valve block, pay attention to the tightening torques of the bolts, damage or displacement of the sealing rings, valves and their bushings from their places. If damage cannot be repaired, replace the control valve block assembly.

- Check torque converter for proper installation (lack of distortion, etc.) and spline damage. If the splines are damaged and repair is not possible, replace the torque converter.

No connection to tester

Unable to communicate with the tester.

Possible causes of the malfunction:

- - malfunction of the diagnostic line,

- - faulty wiring or connector,

- - tester malfunction,

- - malfunction of the electronic control unit for the engine and automatic transmission.

Cannot start engine

It is impossible to start the engine when the automatic transmission selector is in the position "R" or "N".

Possible causes of the malfunction:

- - malfunction of the start inhibit switch,

- - a malfunction in the engine systems,

- - malfunction of the torque converter,

- - malfunction of the electronic control unit for the engine and automatic transmission, - malfunction of the oil pump.

Impossible to move forward

When translating the automatic transmission selector from the position "N" V "D", "3", "2", "L" car does not move forward (with engine idling).

Possible causes of the malfunction:

- - inadequate pressure in the main line,

- - malfunction of the solenoid valve for controlling the downshift clutch,

- - malfunction of the downshift clutch,

- - malfunction of the control solenoid valve block,

- - malfunction of the electronic control unit for the engine and automatic transmission.

Unable to move in reverse gear

When translating the automatic transmission selector from "N" V "R" the car does not move back (with engine idling).

Possible causes of the malfunction:

- - inappropriate pressure in the line of the reverse gear clutch,

- - inappropriate pressure in the line of the brake of the first gear and reverse gear,

- - malfunction of the solenoid valve of the brake of the first gear and reverse gear,

- - malfunction of the reverse gear clutch,

- - malfunction of the brake of the first gear and reverse gear, - malfunction of the control valve block,

- - malfunction of the electronic control unit for the engine and automatic transmission.

Impossible to move forward and in reverse gear

When translating the automatic transmission selector from "N' in any other position the car does not go (with engine idling).

Possible causes of the malfunction:

- inappropriate pressure in the main line, - malfunction of the mechanical part of the automatic transmission,

- - malfunction of the oil pump, - malfunction of the control valve block,

- malfunction of the electronic control unit for the engine and automatic transmission.

The engine stalls when the selector is moved to the driving position ("N" ->"D" or "N" —›"R")

When translating the automatic transmission selector from "N" V "R" or "D" the car is not running (with engine idling).

Possible causes of the malfunction:

- A) malfunction in engine systems,

- V) malfunction of the control solenoid valve block,

- G) malfunction of the torque converter lock-up clutch.

Long shift times only when driving forward

There are jerks or a delay in engaging gears when the automatic transmission selector is moved from "N" V "D" is 2 seconds or more (with engine idling).

Possible causes of the malfunction:

- inappropriate pressure in the line of the downshift clutch,

- malfunction of the solenoid valve for the control of the downshift clutch,

- downshift clutch failure

- malfunction of the control valve block,

- throttle position sensor malfunction

- malfunction of the electronic control unit for the engine and automatic transmission.

Long shift times only when driving in reverse gear

There are jerks or a delay in engaging gears when the automatic transmission selector is moved from "N" V "R" is 2 seconds or more (with engine idling).

Possible causes of the malfunction:

- - inappropriate pressure in the line of the reverse gear clutch,

- inappropriate pressure in the brake line of the first gear and reverse gear, - malfunction of the solenoid valve for controlling the brake of the first gear and reverse gear,

- reverse clutch failure

- - Malfunction of the brake of the first gear and reverse gear. - malfunction of the control valve block,

- - malfunction of the sensor-switch of the fully closed throttle position, - malfunction of the electronic control unit for the engine and automatic transmission.

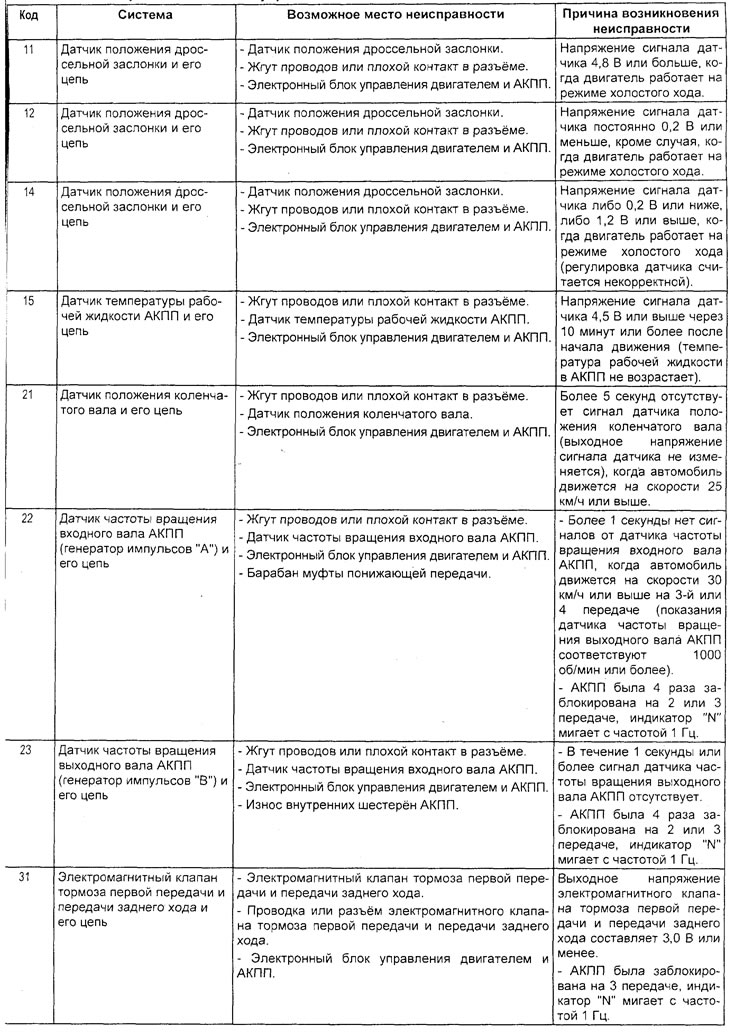

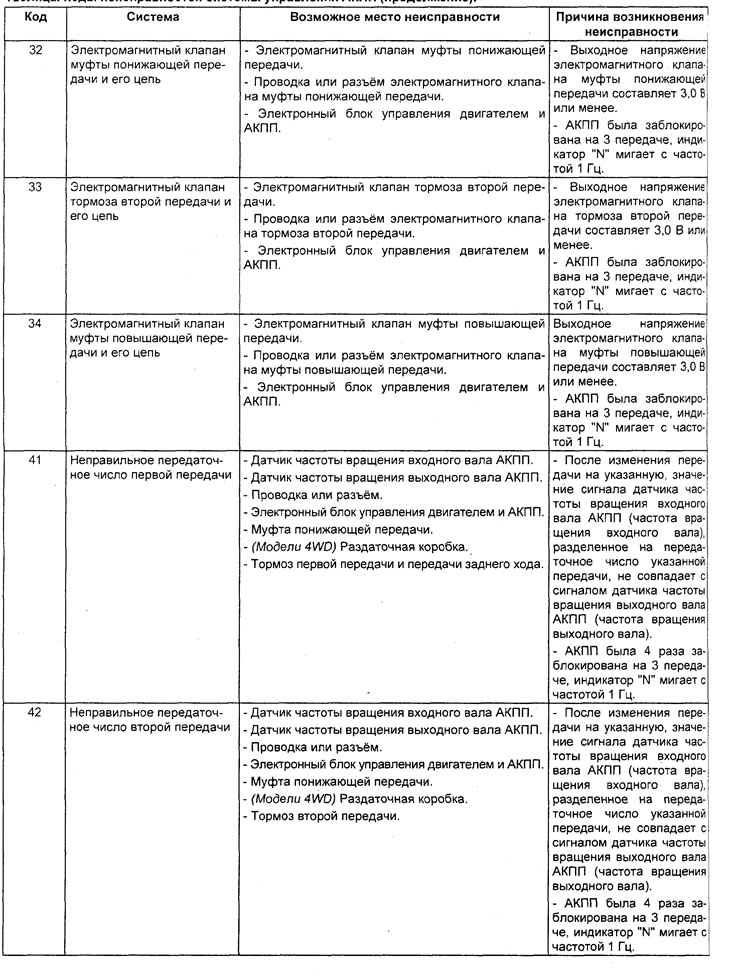

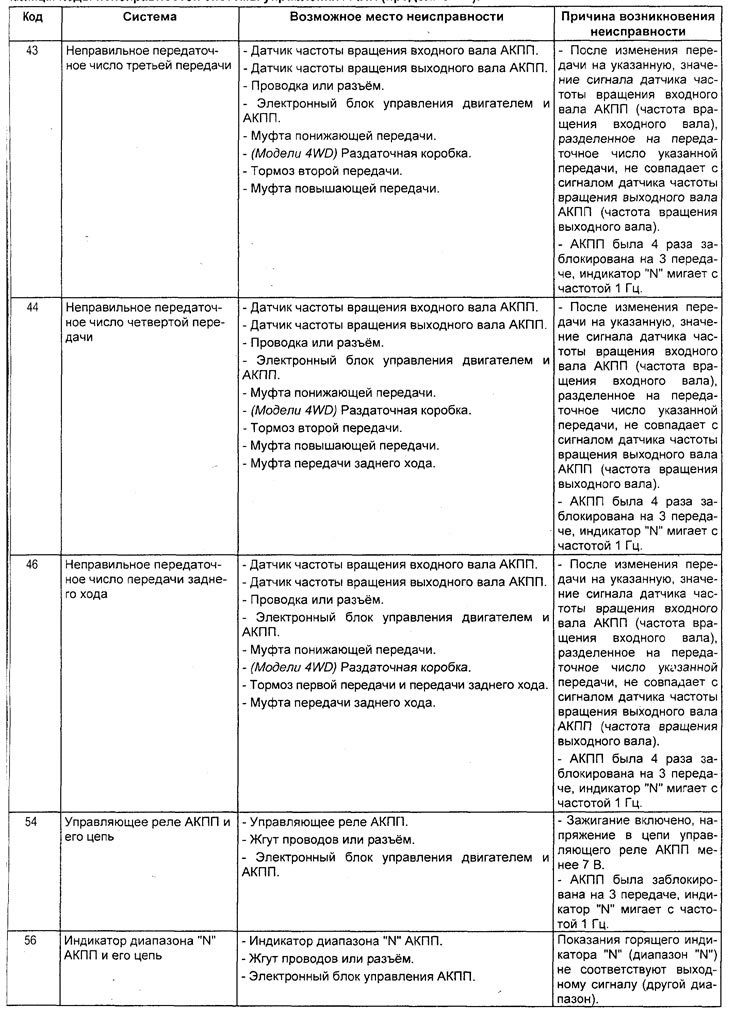

Table. Codes of malfunctions of the automatic transmission control system.

Long shift times in forward and reverse gear

There are jerks or a delay in engaging gears when the automatic transmission selector is moved from "N" V "R". Or from "N" V "D" is 2 seconds or more (with engine idling).

Possible causes of the malfunction:

- inadequate pressure in the main line,

- - malfunction of the oil pump, - malfunction of the control valve block,

- - malfunction of the electronic control unit for the engine and automatic transmission.

Hard hitting when shifting gears (jerks)

Every upshift or downshift is accompanied by jolts (blows), when you try to increase the speed, there is a lack of communication (interactions) between the engine and transmission.

Possible causes of the malfunction:

- - inadequate pressure in the main line,

- - malfunction of solenoid valves,

- - malfunction of the oil pump, - malfunction of the control valve block,

- - malfunction of the brakes and clutches, - malfunction of the electronic control unit for the engine and automatic transmission.

Incorrect shift points for all gears

When the car is moving, all gearshift points are shifted.

Possible causes of the malfunction:

- - malfunction of the pulse generator "IN" (automatic transmission output shaft speed sensor), - malfunction of the throttle position sensor,

- - malfunction of solenoid valves,

- - inadequate pressure in the main line,

- - malfunction of the control solenoid valve block,

- - malfunction of the automatic transmission electronic control unit.

Incorrect shift points for some gears

When the vehicle is moving, some shift points are shifted. This is not a malfunction when changing from one operating mode to another.

Possible causes of the malfunction:

- - malfunction of the control solenoid valve block,

- - malfunction of the automatic transmission electronic control unit.

Gear not shifting, no DTCs

There is no gear shifting while driving, and there are no diagnostic trouble codes.

Causes of malfunction:

- - Malfunction of the starter interlock switch.

- - malfunction of the automatic transmission electronic control unit.

Bad overclocking (injectivity) only when moving forward

There is no acceleration or deceleration during movement.

Possible causes of the malfunction:

- malfunction in engine systems,

- - malfunction of clutches and brakes, - malfunction of the automatic transmission electronic control unit.

Vibration

Vibration occurs when driving at a constant speed, accelerating or decelerating.

Possible causes of the malfunction:

- - a malfunction in the engine systems,

- - malfunction of the torque converter,

- - malfunction of the control solenoid valve block,

- - malfunction of the automatic transmission electronic control unit.

Defective start inhibit switch or circuit

Possible causes of the malfunction:

- - malfunction of the start inhibit switch,

- - malfunction of the ignition switch,

- - faulty connectors or wiring,

- - malfunction of the automatic transmission electronic control unit.

Defect of the vehicle speed sensor or its circuit

Possible causes of the malfunction:

- - Malfunction of the automatic transmission output shaft speed sensor.

- - Faulty instrument cluster.

- - Faulty connectors or wiring.

- - Malfunction of the electronic control unit for the engine and automatic transmission.

Defective dual refrigerant pressure switch or circuit

Possible causes of the malfunction:

- - Malfunction of the double refrigerant pressure switch.

- - Faulty connectors or wiring.

- - Malfunction of the electronic control unit for the engine and automatic transmission.

Checks on the connector of the electronic engine control unit and automatic transmission

Note:

- - If any deviation from the nominal value is found, then check the corresponding sensor, actuator and wires.

- - After repairing or replacing a unit, recheck to ensure that the problem has been corrected.

- - Follow the table "Checking the voltage at the terminals of the automatic transmission electronic control unit"

1. Disconnect the control box connector and connect the test harness between the connectors, or use a voltmeter needle tester to test at the connector on the harness side.

Attention: probe short circuit "pluses" voltmeter connected to the output of the connector, on "mass" may cause damage to the wiring, sensor, electronic control unit, or all of the above items.

2. With the control unit connector connected, measure the voltage between the terminals "masses" control unit and each corresponding terminal of the unit connector.