Disassembly

The main preliminary operations that you need to pay attention to are given in the sections "Replacement of oil seals" And "Replacing the cylinder head gasket" chapters "MPI motors - mechanical".

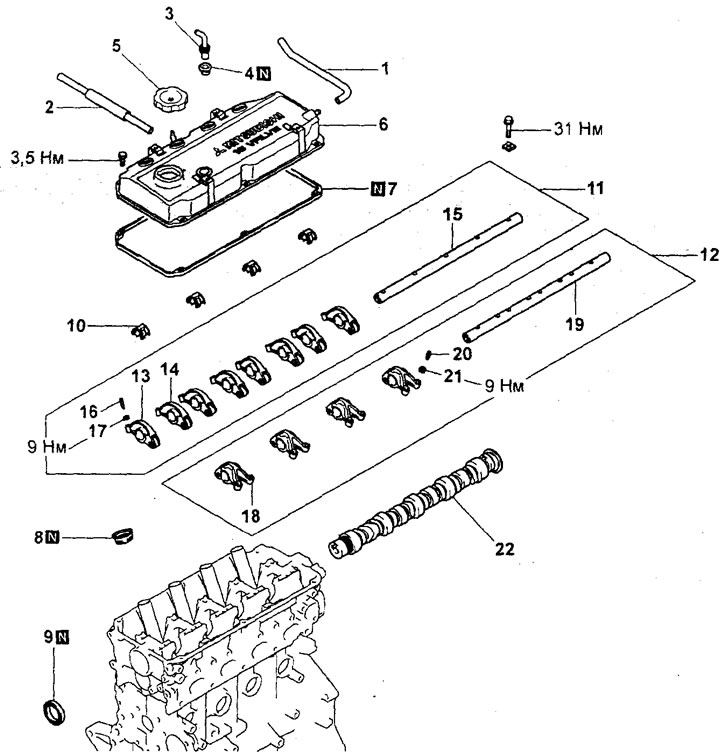

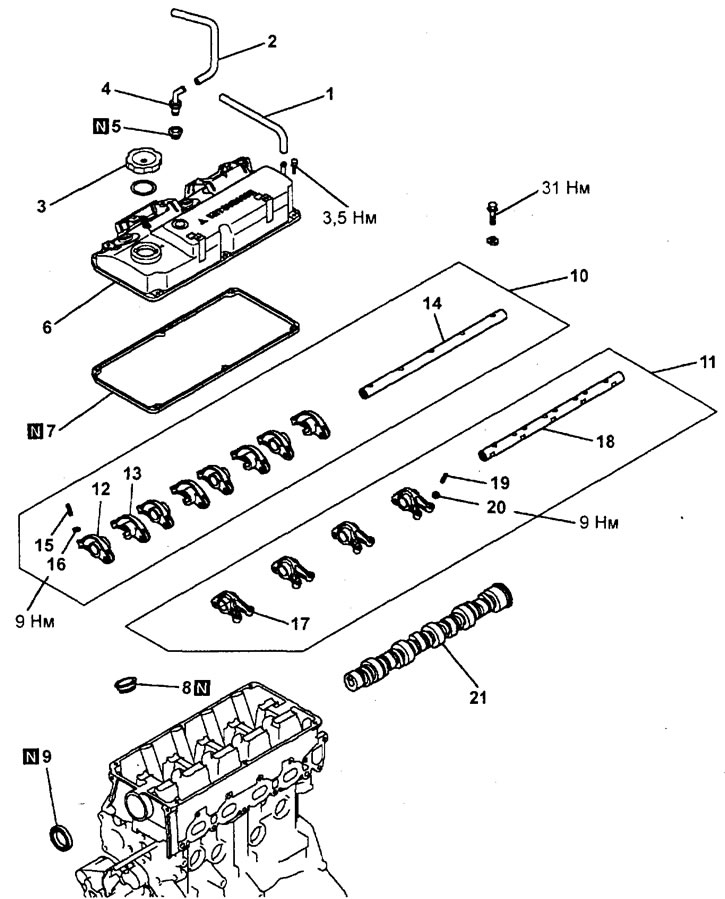

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the axis of the rocker arms and camshaft".

When removing parts, pay attention to the following operations:

1. Removing the rocker axles and rocker arms.

Attention:

- Do not disassemble the rocker arm axle assembly with rocker arms unless absolutely necessary.

- If it is necessary to disassemble the rocker shaft, lay out the rocker arms according to the cylinder number and intake / exhaust valves so as not to confuse them during assembly.

2. Removing the camshaft.

Attention: be careful not to damage the camshaft when removing it from the cylinder head.

Examination

Checking the camshaft

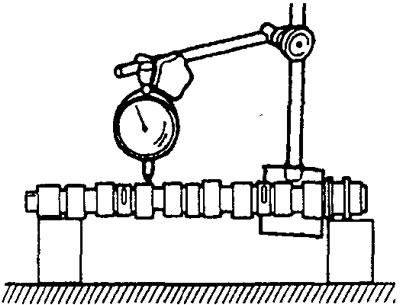

1. Checking the axial clearance of the camshaft.

A) Measure the camshaft end play when the camshaft is installed in the cylinder head.

Axial clearance:

- nominal - 0.05 - 0.08 mm

- maximum allowable - 0.20 mm

b) If the camshaft end play is greater than the limit, replace the camshaft and cylinder head.

Removing the axis of the rocker arms and camshaft (4G93 engine).1 - vent hose, 2 - PCV hose, 3 - PCV valve, 4 - PCV valve gasket, 5 - oil filler cap, 6 - cylinder head cover, 7 - cylinder head cover gasket, 8 - cover seal cylinder heads (under the candles), 9 - camshaft oil seal, 10 - rocker shaft spring, 11 - rocker shaft assembly (for intake valves), 12 - rocker arm assembly (for exhaust valves), 13 - valve rocker "IN", 14 - valve rocker "A", 15 - rocker arm axis, 16 - adjusting screw, 17 - lock nut, 18 - valve rocker "WITH", 19 - rocker arm axis, 20 - adjusting screw, 21 - locknut, 22 - camshaft.

2. Inspect the camshaft journals, check for scoring. If there are scuffs, replace the camshaft, check the condition of the shaft bed in the cylinder head and clean the oil passage in the cylinder head.

3. Check the diameter of the camshaft support pins. If their measured value does not correspond to the nominal value, then check the oil clearance between the journal and the camshaft bearing.

Rated value:

- 4G15 engine - 45.93 - 45.94 mm

- 4G93 engine - 45.0 mm

4. Determine the camshaft oil clearance. If the clearance in any bearing exceeds the maximum allowable value, then replace the camshaft and cylinder head.

Oil clearance:

- Nominal - 0.05 - 0.09 mm

- Maximum allowable - 0.12 mm

5. Check up a condition of a surface of cams of a camshaft.

6. Measure the height of the camshaft cams and, if the measured value is less than the maximum allowable value, then replace the camshaft.

Jaw height:

Engine 4G15:

| Cam | Rated | Limit. |

| Inlet | 37.30 mm | 36.80 mm |

| High school graduation | 37.16 mm | 36.66 mm |

Engine 4G93:

| Cam | Rated | Limit. |

| Inlet | 37.53 mm | 37.03 mm |

| High school graduation | 37.64 mm | 37.14 mm |

7. Install the camshaft on the supports (on the extreme support necks). Measure the runout of the shaft on the middle neck. If the runout exceeds the limit, replace the camshaft.

Camshaft runout:

- nominal less than —— 0.02 mm

- maximum allowable - 0.10 mm

Checking rocker arms and rocker axles

1. Check the surface of the pressure roller of the valve rocker and the rocker pusher, replace the rocker if there is significant local wear, damage, scoring.

2. Check the rotation of the pressure roller and replace the valve rocker if there is sticking or excessive play.

3. Measure the inside diameter of the rocker arm bushing (under axle), replace the rocker if there is excessive wear or scoring.

4. Check the outer part of the surface (around the circumference) the axis of the rocker arms, on which the rocker arm is installed for the absence of uneven or increased wear. Replace the rocker shaft if there is obvious damage or nicks.

5. Check up absence of clogging of oil apertures in an axis of yokes. Clean oil holes if necessary.

6. Check up a backlash between the plug of a yoke and an axis of yokes. If the clearance exceeds the nominal value, then replace the rocker arms and the rocker shaft.

Nominal clearance - 0.02 - 0.05 mm

Assembly

Installation of details is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

Caution: When assembling, apply engine oil to all moving parts.

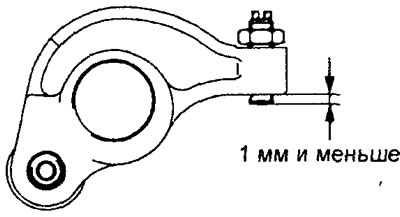

1. Installing the adjusting screw.

Install the screw on the rocker and temporarily fix it with a nut.

Removing the axis of the rocker arms and camshaft (4G15 engine).1 - vent hose, 2 - positive crankcase breather hose, 3 - oil filler cap, 4 - positive crankcase breather valve, 5 - positive crankcase breather valve gasket, 6 - cylinder head cover, 7 - cylinder head cover gasket, 8 - cylinder head cover seal (under the candles), 9 - camshaft seal, 10 - rocker arm assembly (for intake valves), 11 - rocker arm assembly (for exhaust valves), 12 - valve rocker "A", 13 - valve rocker "IN", 14 - rocker arm axis, 15 - adjusting screw, 16 - lock nut, 17 - valve rocker "WITH", 18 - rocker shaft, 19 - adjusting screw, 20 - locknut, 21 - camshaft.

Make sure that the end of the screw is flush with the surface of the rocker or that its protrusion relative to this surface does not exceed 1 mm.

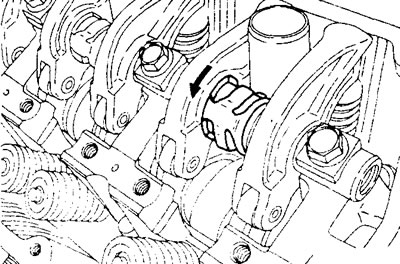

2. Installing the camshaft. Before installing the camshaft in the cylinder head, lubricate the bearing journals and camshaft cams with engine oil.

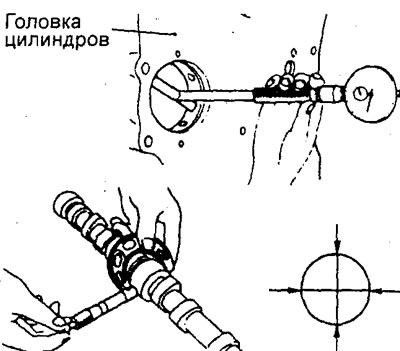

3. Installation of rocker arms, rocker axles and rocker axle springs.

A) Install and lightly tighten the bolts of the intake rocker arm shaft so that none of the rocker arms presses on the valves.

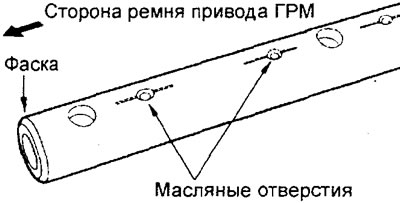

Note: Before installing the rocker axles, check the following:

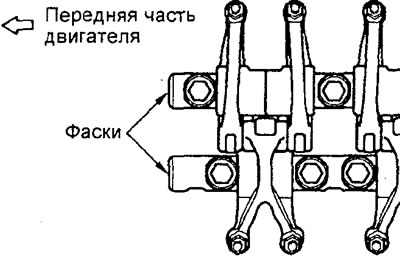

- The rocker axle with four bolt holes is mounted on the side of the intake valves.

- The oil holes of the rocker arm axis face down when installed (located on the side of the cylinder head).

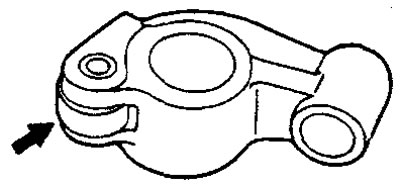

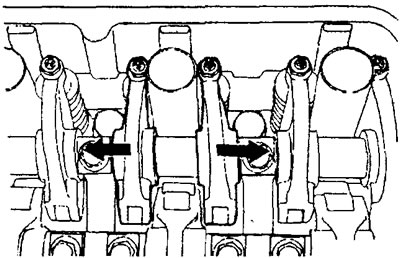

b) Before tightening the rocker axle mounting bolts, move the corresponding rocker arms in the directions indicated by the arrows in the figure.

Note: After moving the rocker arms, make sure they touch the rocker shaft mounting tabs on the cylinder head.

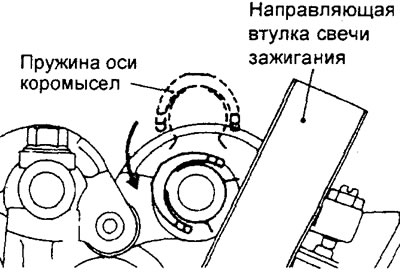

V) Install the rocker spring on top of the axle so that it is at right angles to the spark plug guide.

Note: You must install the rocker shaft springs before installing the rocker shaft with exhaust rockers.

G) Make sure that the chamfers of each axis of the rocker arms are located as shown in the figure.

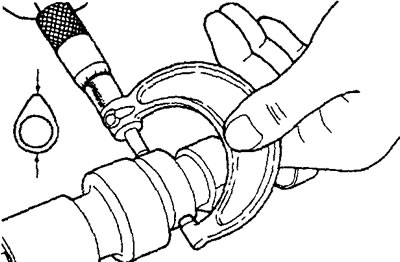

4. Installing the camshaft seal.

Note: the operation for installing the camshaft oil seal is given in the section "Replacement of oil seals" chapters "MPI motors - mechanical".

Other final operations that you need to pay attention to are given in the sections "Replacement of oil seals" And "Replacing the cylinder head gasket" chapters "MPI motors - mechanical".