Removal and installation

1 Before starting to remove parts, relieve residual pressure from the high pressure fuel line.

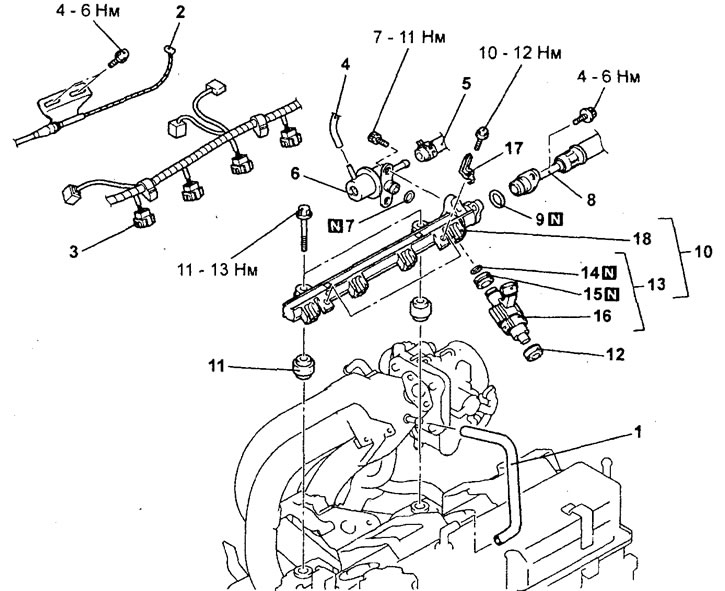

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing nozzles".

Removing nozzles (4G15 engine).1 - positive crankcase ventilation hose connection, 2 - accelerator pedal cable connection, 3 - injector connector, 4 - vacuum hose connection, 5 - fuel return hose connection, 6 - fuel pressure regulator, 7 - O-ring, 8 - high pressure fuel hose connection pressure, 9 - O-ring, 10 - fuel manifold assembly, 11 - insulator, 12 - insulator, 13 - injector assembly, 14 - O-ring, 15 - o-ring, 16 - injector, 17 - injector wiring harness retainer bracket, 18 - fuel manifold.

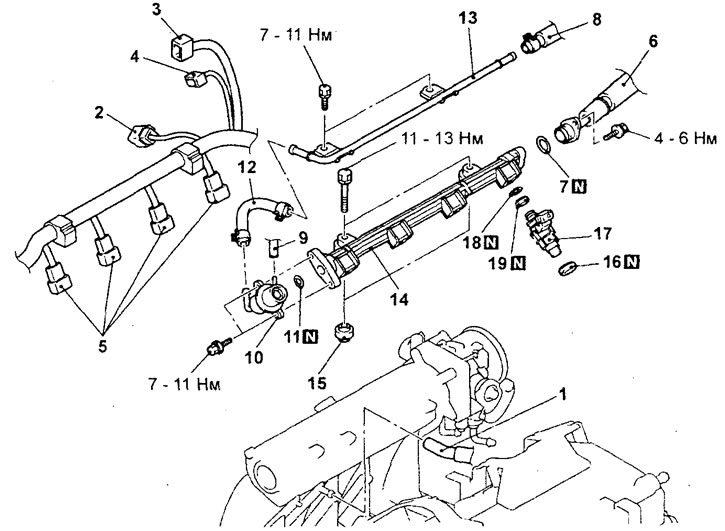

Removing nozzles (4G15 engine).1 - positive crankcase ventilation hose connection, 2 - accelerator pedal cable connection, 3 - injector connector, 4 - vacuum hose connection, 5 - fuel return hose connection, 6 - fuel pressure regulator, 7 - O-ring, 8 - high pressure fuel hose connection pressure, 9 - O-ring, 10 - fuel manifold assembly, 11 - insulator, 12 - insulator, 13 - injector assembly, 14 - O-ring, 15 - o-ring, 16 - injector, 17 - injector wiring harness retainer bracket, 18 - fuel manifold. Removing nozzles (4G93 engine).1 - Crankcase ventilation hose connection, 2 - EGR valve servo connector, 3 - Throttle position sensor connector, 4 - Idle speed control servo connector, 5 - Injector connector, 6 - High pressure fuel hose connection, 7 - O-ring, 8 - fuel return hose connection, 9 - vacuum hose connection, 10 - fuel pressure regulator, 11 - O-ring, 12 - fuel hose, 13 - fuel return pipe, 14 - fuel manifold, 15 - insulator, 16 - insulator, 17 - nozzle assembly, 18 - O-ring, 19 - O-ring.

Removing nozzles (4G93 engine).1 - Crankcase ventilation hose connection, 2 - EGR valve servo connector, 3 - Throttle position sensor connector, 4 - Idle speed control servo connector, 5 - Injector connector, 6 - High pressure fuel hose connection, 7 - O-ring, 8 - fuel return hose connection, 9 - vacuum hose connection, 10 - fuel pressure regulator, 11 - O-ring, 12 - fuel hose, 13 - fuel return pipe, 14 - fuel manifold, 15 - insulator, 16 - insulator, 17 - nozzle assembly, 18 - O-ring, 19 - O-ring.When removing parts, pay attention to the operation to remove the heated collector.

Attention: be careful when pcs fuel manifold tope with injectors, don't drop the injectors.

Installation is made in an order, the return to removal.

When installing parts, pay attention to the operation of installing injectors, fuel pressure regulator (flange) and high pressure fuel hose (flange).

A) Apply some clean engine oil to the element O-ring.

Attention: be careful not to let engine oil get into the fuel manifold.

6) Be careful not to damage the o-ring when installing. Turning the element from side to side, connect them to the fuel manifold. After connecting, check that the element rotates freely without binding.

V) If the element does not turn smoothly, the O-ring may have been pinched. In this case, disconnect the element, check the condition of the gasket, if necessary, replace it. Then reconnect and check for smooth rotation again.

G) Tighten the high pressure fuel hose flange and fuel pressure regulator flange bolts to rated torque.

Torque:

- fuel pressure regulator flange bolt - 9.0±2 N.m

- high pressure fuel hose flange bolt - 5.0±1 N.m

After completing the installation of the parts, perform the following operations:

- A) Check for fuel leaks at the connections.

- 6) (Engine 4G15) Adjust the accelerator pedal cable.