Removal and installation of injection pump

− Before starting to remove parts, carry out the following operations:

- A) Remove the engine cover.

- b) Release any residual pressure from the high pressure fuel line,

- V) Remove the air filter.

- G) Remove the throttle body.

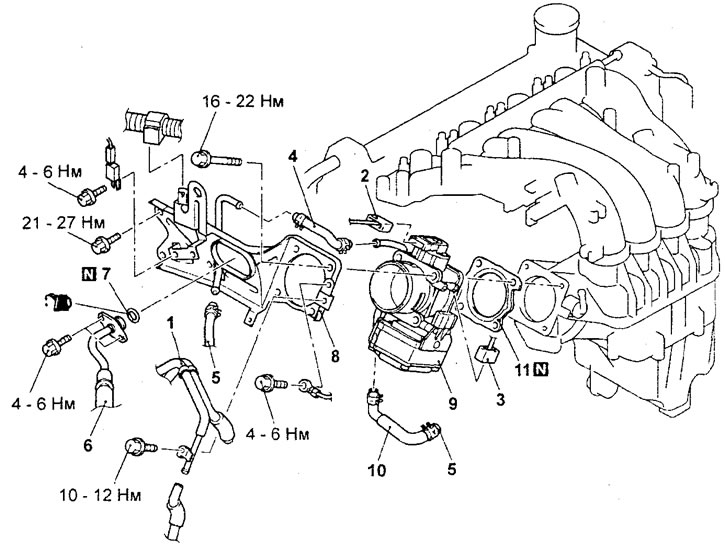

Removal is carried out in the order of the numbers indicated in the figure "Removal of injection pump".

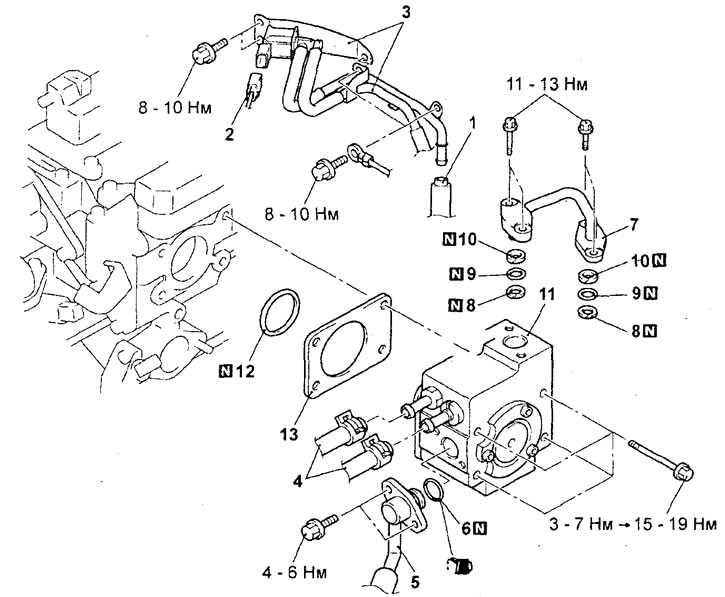

Removal of injection pump (4G15 engine). 1 - connection of the vacuum hose of the adsorber; 2 - connector for the canister purge solenoid valve; 3 - bracket for the canister purge solenoid valve and vacuum tubes and hoses as an assembly; 4 - fuel return hose connection; 5 - connection of the inlet fuel hose; 6 - ring gasket; 7 - high pressure fuel pipe (fuel supply); 8 - support washer "A"; 9 - ring gasket; 10 - support washer "IN"; 11 - injection pump; 12 - ring gasket; 13 - insulator.

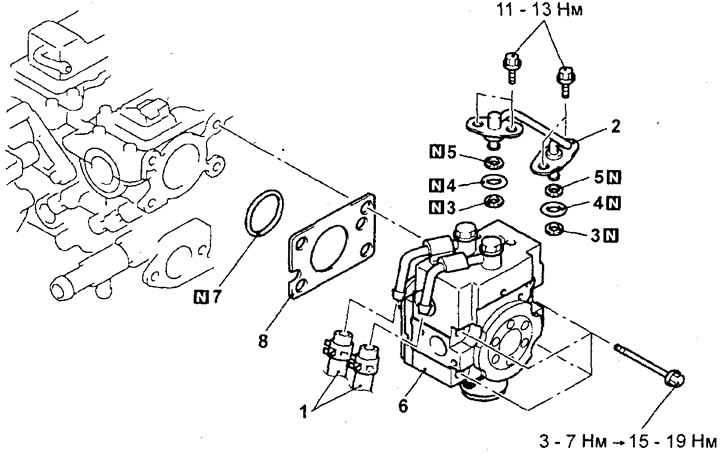

Removal of injection pump (4G93 engine). 1 - fuel return hose connection; 2 - high pressure fuel pipe (fuel supply); 3 - support washer "A"; 4 - ring gasket; 5 - support washer "IN"; 6 - injection pump; 7 - ring gasket; 8 - insulator.

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

1. Installation of injection pump, high pressure fuel pipe (fuel supply), support washer "A", O-ring and support washer "IN".

A) Apply a small amount of clean engine oil to the outer O-ring of the high pressure pump extension and the high pressure pump drive roller.

Attention: do not allow engine oil to get inside the injection pump.

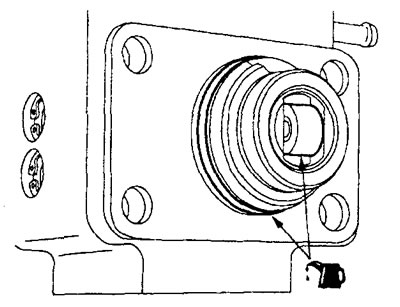

Engine 4G15.

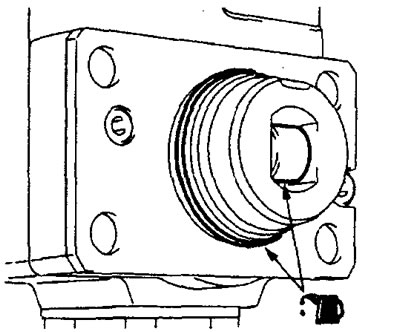

Engine 4G93.

b) Insert the protrusion of the injection pump straight into the corresponding hole in the cylinder head. Make sure that the protruding part of the injection pump is inserted securely, evenly, without distortions, then pre-tighten the injection pump mounting bolts with a small torque (a little more than hand-tight).

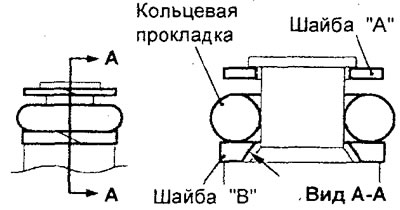

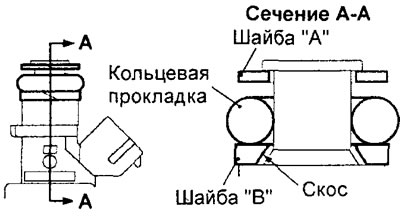

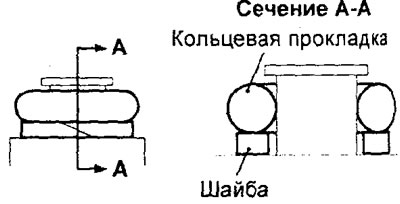

V) Install the support washer "IN", O-ring and support washer "A" on the high pressure fuel pipe as shown.

Attention:

- Install the support washer "IN" beveled surface away from the O-ring.

- Make sure the support washer is installed correctly "A" (outer diameter 14.8 mm). Will not confuse the support washer "A" from the support washer of the fuel pressure sensor.

G) Apply a small amount of clean engine oil to the high pressure fuel line O-ring.

Attention: do not allow engine oil to get inside the injection pump and inside the fuel manifold.

d) Insert the high pressure fuel pipe evenly into the injection pump and into the fuel manifold. Make sure that the fuel pipe is inserted securely, evenly, without distortion, then tighten the fuel pipe mounting bolts to the specified torque.

Tightening torque - 11 - 13 Nm

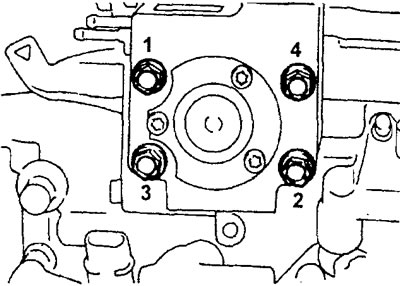

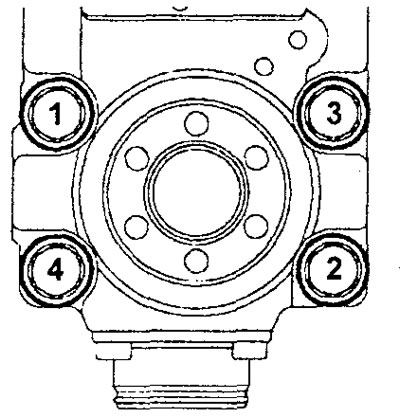

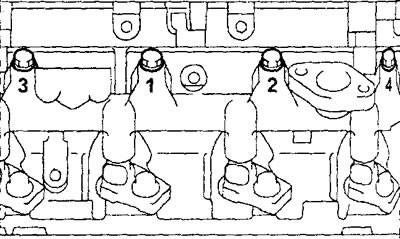

e) Tighten the injection pump mounting bolts to 5 + 2 Nm in the order shown in the figure.

Note: When tightening, use a torque wrench with a scale increment of 0.5 Nm.

Engine 4G15.

Engine 4G93.

and) Finally tighten the injection pump mounting bolts to 17±2 Nm.

2. Install O-ring and fuel inlet hose.

A) Apply a small amount of clean engine oil to the fuel inlet hose O-ring.

Attention: do not allow engine oil to get inside the injection pump.

b) Be careful not to damage the o-ring when installing. Turning the fuel hose flange from side to side, connect it to the injection pump. After connecting, check that the flange turns freely without binding.

V) If the fuel hose flange does not turn smoothly, the O-ring may be pinched. In this case, disconnect the fuel hose, check the condition of the gasket, replace it if necessary. Reconnect the fuel hose and check again for smooth rotation of the flange.

G) Tighten the hose mounting bolts to the specified torque.

Tightening torque - 5±1 Nm

3. Installing the fuel return hose.

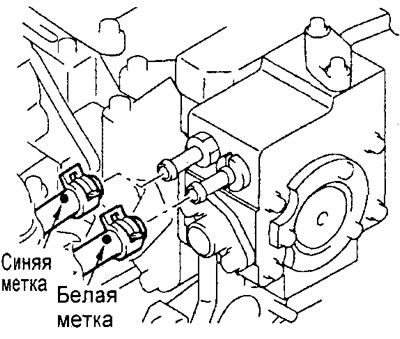

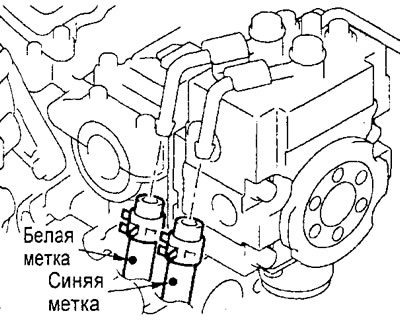

Install the fuel return hose with the identification mark facing as shown.

Engine 4G15.

Engine 4G93.

4. Removal of air from the high pressure fuel supply.

A) Start the engine and let it run at 2000 rpm for 15 seconds or more to bleed air from the injection pump.

b) When DTC P0190 is found (incorrect fuel pressure), erase it with a tester.

Note: DTC P0190 will be set if the fuel pipe has been removed and air has entered the high pressure fuel line or injection pump.

After completing the installation of the parts, perform the following operations:

- A) Install the throttle body.

- 6) Install the air filter.

- V) Perform the High Pressure Fuel Line Bleeding Procedure.

- G) Check for fuel leaks.

- d) Install the engine cover.

Removal and installation of nozzles

Before you start removing parts, do the following:

- A) Remove the engine cover.

- b) Release residual pressure from the high pressure fuel line.

- V) Disconnect the wire from the negative battery terminal.

- G) (Engine 4G15) Remove the air filter.

- d) (Engine 4G15) Remove the throttle body.

- e) (Engine 4G15) Remove the intake manifold.

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing nozzles".

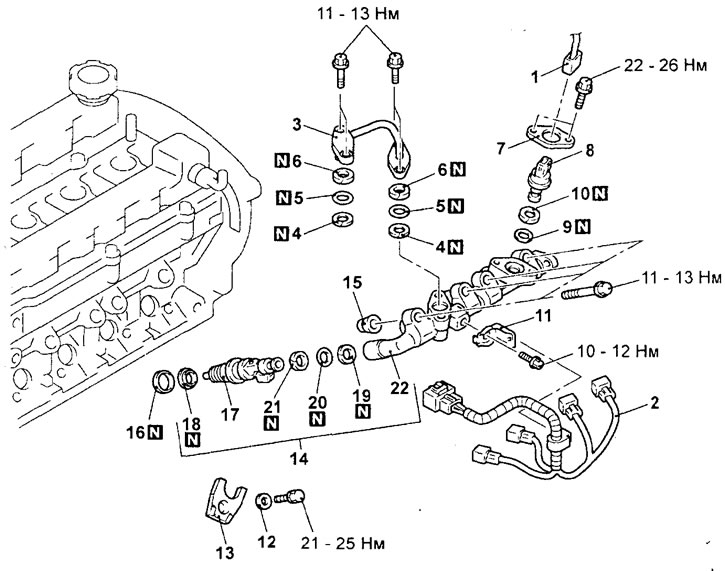

Removing nozzles (4G15 engine). 1 - fuel pressure sensor connector; 2 - injector wiring harness connector; 3 - high pressure fuel pipe (fuel supply); 4 - support washer "A"; 5 - ring gasket; 6 - support washer "IN"; 7 - flange; 8 - fuel pressure sensor; 9 - ring gasket; 10 - support washer; 11 - bracket for the injector wiring harness retainer; 12 - washer; 13 - nozzle holder; 14 - fuel manifold assembly; 15 - insulator; 16 - gasket; 17 - nozzle; 18 - curly washer; 19 - support washer "A"; 20 - ring gasket; 21 - support washer "IN"; 22 - fuel manifold.

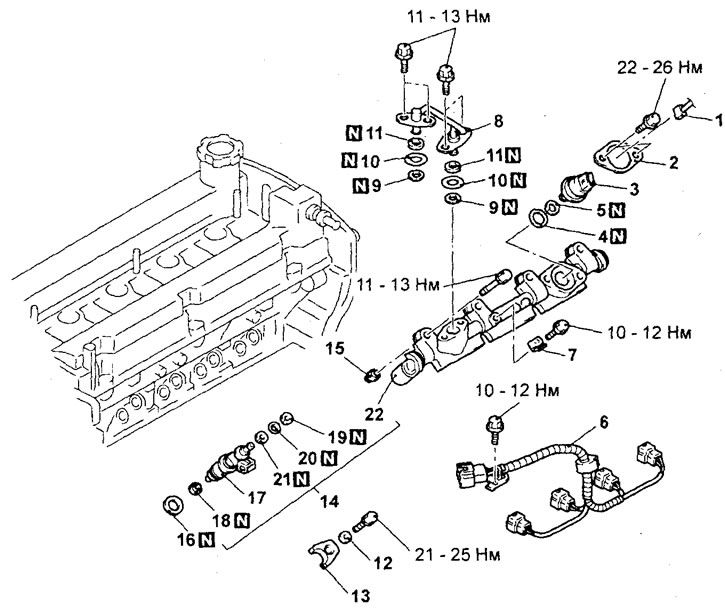

Removing nozzles (4G93 engine). 1 - fuel pressure sensor connector; 2 - flange; 3 - fuel pressure sensor; 4 - ring gasket; 5 - support washer (remove the air filter; throttle body and intake manifold); 6 - injector wiring harness connector; 7 - bracket for the injector wiring harness retainer; 8 - high pressure fuel pipe (fuel supply); 9 - support washer "A"; 10 - ring gasket; 11 - support washer "IN"; 12 - washer; 13 - nozzle holder; 14 - fuel manifold assembly; 15 - insulator; 16 - gasket; 17 - nozzle; 18 - curly washer; 19 - support washer "A"; 20 - ring gasket; 21 - support washer "IN"; 22 - fuel manifold.

When removing parts, pay attention to the following operations:

1. Removing the flange.

If the fuel pressure sensor is to be reused, mark the flange and the sensor before removing the flange.

Note: when tightening the fastening to the engine, the flange is deformed. Therefore, to ensure that the fuel pressure sensor is properly sealed and installed correctly, it is necessary to make marks as shown in the figure in order to reinstall the sensor in its original position. When replacing the fuel pressure sensor, it is replaced only together with the flange.

2. Removing the fuel manifold. Remove the fuel manifold assembly with injectors.

Caution: Be careful not to drop the injectors when removing the fuel manifold.

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

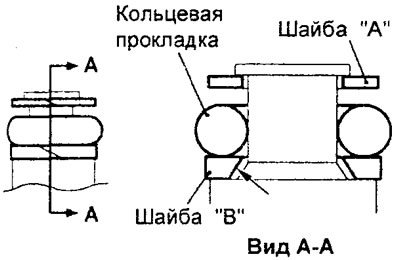

1. Installing the support washer "IN", O-ring, support washer "A" and figured washer nozzles.

A) Install washers and O-ring as shown.

Attention:

- Install the support washer "IN" beveled surface away from the O-ring.

- Check that the support washer is installed correctly "A" (outer diameter 14.8 mm). Do not confuse the support washer "A" with fuel pressure sensor support washer.

6) Before installing a new figured washer, apply white petroleum jelly to it. Be careful to make sure the figured washer is installed correctly (see picture).

Attention: the figured washer should always be replaced during disassembly and assembly work, since when the washer is reused, fuel leakage or gas breakthrough is possible.

2. Installing the fuel manifold assembly with injectors.

A) Apply a small amount of clean engine oil to the O-ring.

Attention: be careful not to let engine oil get into the fuel manifold.

b) Be careful not to damage the O-ring when installing. Turning the nozzle from side to side, install it in the fuel manifold. After connecting, make sure the nozzle turns freely.

V) If the nozzle turns with jamming, then most likely the O-ring is pinched. In this case, remove the nozzle, check the condition of the seal and, if necessary, replace it, and then reinstall the nozzle.

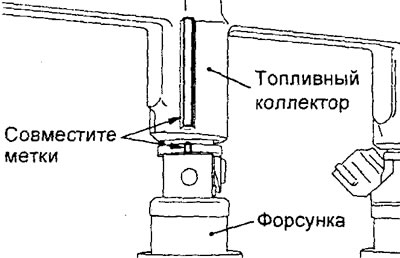

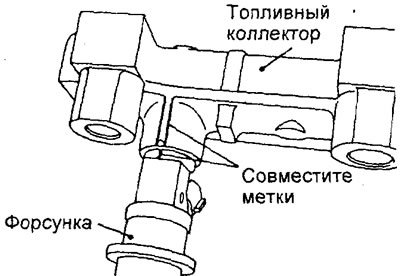

G) Align the alignment marks on the fuel manifold and injectors.

Engine 4G15.

Engine 4G93.

d) Install gaskets on the cylinder head bore for the injectors and insulators. To prevent the insulators from falling, apply petroleum jelly to them.

e) Install the fuel manifold with injectors on the cylinder head and pre-tighten the mounting bolts.

and) Install the nozzle holders with washers and tighten their fastening bolts to the nominal torque.

Tightening torque - 21 - 25 Nm

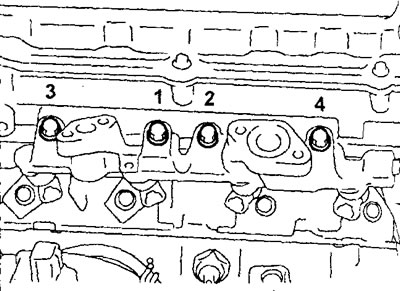

h) Tighten the fuel manifold mounting bolts to the specified torque in the order shown in the figure.

Tightening torque - 11 - 13 Nm

Engine 4G15.

Engine 4G93.

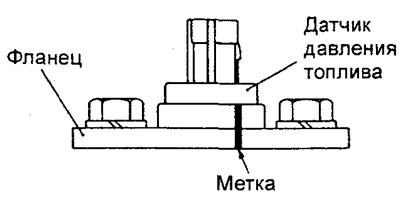

3. Installing the support washer and O-ring.

Install the support washer and O-ring as shown in the illustration.

Attention: do not confuse the support washer with the support washer "A", mounted on the nozzle and high pressure fuel pipe (fuel supply) (outer diameter 15.1 mm).

4. Installation of the fuel pressure sensor and flange.

A) Apply a small amount of clean engine oil to the O-ring.

Caution: Do not allow engine oil to enter the fuel manifold.

b) Install the fuel pressure sensor in the position as shown in the illustration. If the fuel pressure sensor is being reused, align the match marks on the flange and on the sensor.

Caution: When replacing the fuel pressure sensor, always replace it with a pole flange.

5. Installing the support washer "IN", O-ring, support washer "A" and high pressure fuel line (fuel supply).

A) Install the support washer "IN", O-ring and support washer "A" on the high pressure fuel pipe as shown.

Attention:

- Install the support washer "IN" beveled surface away from the O-ring.

- Make sure the support washer is installed correctly "A" (outer diameter 14.8 mm). Do not confuse the support washer "A" with fuel pressure sensor support washer.

b) Apply a small amount of clean engine oil to the high pressure fuel line O-ring.

Caution: Do not allow peat oil to enter the high pressure pump or the fuel manifold.

V) Insert the high pressure fuel pipe evenly into the injection pump and into the fuel manifold. Make sure that the fuel pipe is inserted securely, evenly, without distortion, then tighten the fuel pipe mounting bolts to the specified torque.

Tightening torque - 11 - 13 Nm

After completing the installation of the parts, perform the following operations:

- A) (Engine 4G15) Install the intake manifold.

- b) (Engine 4G15) Install the throttle body.

- V) (Engine 4G15) Install the air filter.

- G) Connect the wire to the negative battery terminal.

- d) Perform High Pressure Fuel Line Bleeding Procedure (see paragraph "4" subsection "Removal and installation of injection pump").

- e) Check for fuel leaks.

- and) Install the engine cover.

Removal and installation of the throttle body

Before you start removing parts, do the following:

- A) Remove the engine cover.

- b) Drain the coolant.

- V) Remove the air filter.

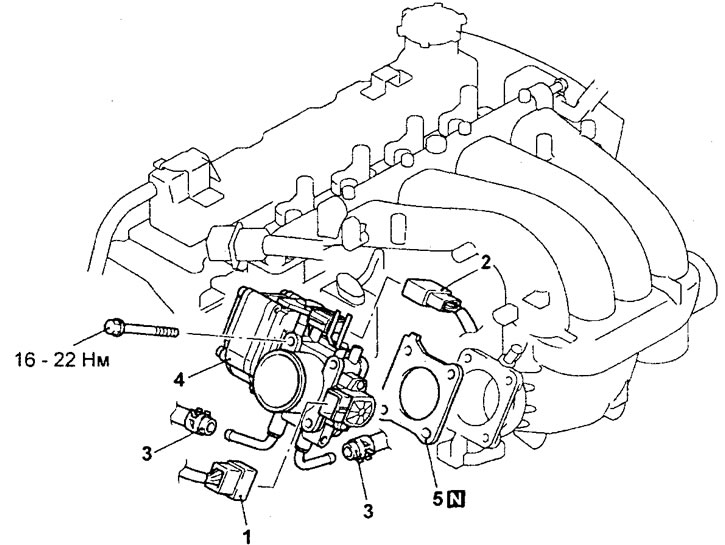

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the throttle body".

Removing the throttle body (4G15 engine). 1 - Throttle position sensor connector, 2 - Throttle servo connector, 3 - Coolant hose connection, 4 - Throttle body assembly, 5 - Throttle body gasket.

Removing the throttle body (4G93 engine). 1 - vacuum tubes and hoses assy; 2 - throttle position sensor connector; 3 - throttle servo connector; 4 - connection of the cooling system hose; 5 - connection of the cooling system hose; 6 - connection of the inlet fuel hose; 7 - ring gasket; 8 - throttle body bracket; 9 - throttle body assembly; 10 - hose of the cooling system; 11 - throttle body gasket.

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

Attention: if the throttle position sensor is removed, it must be adjusted.

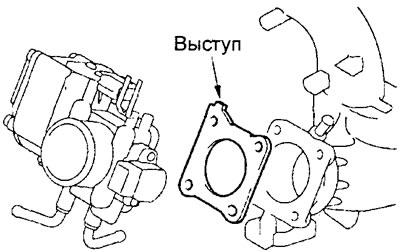

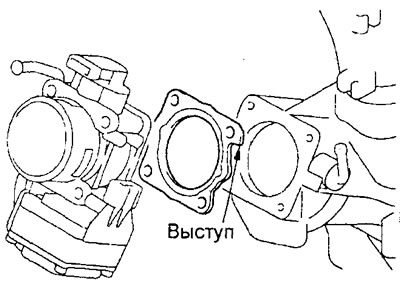

1. Install the throttle body gasket.

Install the housing gasket so that its tab is positioned as shown in the illustration.

Engine 4G15.

Engine 4G93.

2. (Engine 4G93) Installing the O-ring and fuel inlet hose.

A) Apply a small amount of clean engine oil to the fuel inlet hose O-ring.

Attention: do not allow engine oil to get inside the injection pump.

b) Be careful not to damage the o-ring when installing. Turning the fuel hose flange from side to side, connect it to the injection pump. After connecting, check that the flange turns freely without binding.

V) If the fuel hose flange does not turn smoothly, the O-ring may be pinched. In this case, disconnect the fuel hose, check the condition of the gasket, replace it if necessary. Reconnect the fuel hose and check again for smooth rotation of the flange.

G) Tighten the hose mounting bolts to the specified torque.

Tightening torque - 4 - 6 Nm

3. Initialization of the throttle control system after installing the throttle body.

Note: The throttle control system is only initialized if the throttle body assembly has been replaced.

A) Turn the ignition key to position "ON", then within one second turn the ignition key to the "LOCK" ("OFF").

b) Leave the ignition key in position "LOCK" ("OFF") for at least 10 seconds.

After completing the installation of the parts, perform the following operations:

- A) Install the air filter

- b) Fill in the coolant

- V) Install the engine cover.

Removal and installation of the throttle servo controller

Before you start removing parts, do the following:

- A) Remove the glove box.

- b) Remove the front side door sill trim and front side trim.

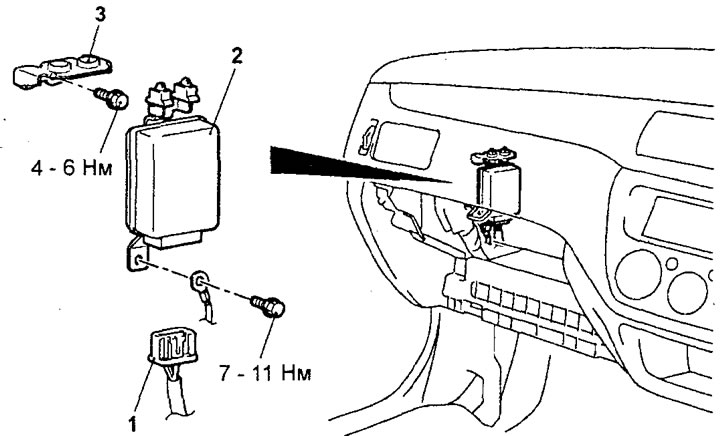

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the throttle servo controller".

Removing the throttle servo controller. 1 - controller connector, 2 - throttle servo controller, 3 - bracket.

Installation is made in an order, the return to removal.

After completing the installation of the parts, perform the following operations:

- A) Install the front side trim and front side door sill trim.

- b) Install the storage box.

- If the throttle servo controller has been replaced, the throttle control system initialization procedure must be performed.

- A) Turn the ignition key to position "ON", then within one second turn the ignition key to the "LOCK" ("OFF").

- b) Leave the ignition key in position "LOCK" ("OFF") for at least 10 seconds.

Removal and installation of the injector control signal generator

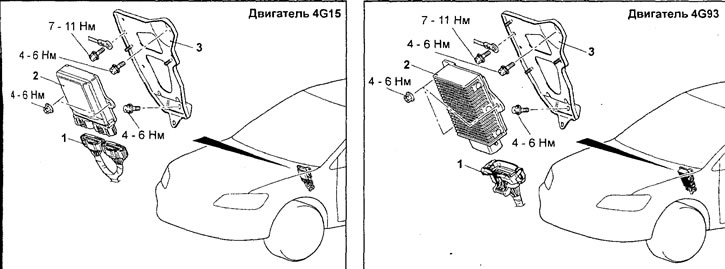

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the injector control signal generator".

Removing the injector control signal generator. 1 - injector control signal generator connector, 2 - injector control signal generator, 3 - mounting bracket.

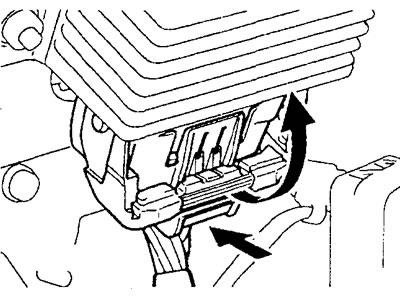

(Engine 4G93) When removing parts, pay attention to the operation to remove the injector control signal generator.

Press the connector at the location shown by the arrow in the illustration to disconnect the connector.

Attention:

- Before disconnecting the connector of the injector control signal generator, it is necessary to disconnect the wire from the negative terminal of the battery.

- During engine operation, the injector driver housing becomes very hot, so be careful when removing it.

Installation is made in an order, the return to removal.