Note: The procedure for reading diagnostic trouble codes using a tester and the procedure for diagnosing a car are given in the appropriate section of the chapter "fuel injection system (MPI)".

General information

The procedure is given in the relevant section of the chapter "fuel injection system (MPI)".

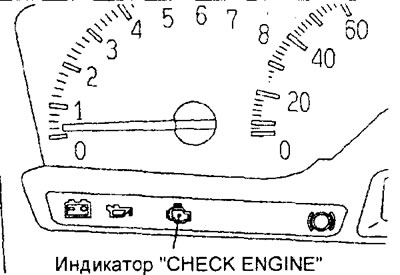

Checking the indicator "CHECK ENGINE" (check the engine)

1. Turn on the ignition (position "ON" key in the lock) and make sure the indicator "CHECK ENGINE" lights up for about 5 seconds and then goes out.

2. If the indicator does not light, then check the wiring, fuse and indicator lamp.

3. If the indicator stays on after starting the engine or lights up when the engine is running, check for trouble codes. The indicator lights up when the self-diagnosis system detects a malfunction in the electronic control unit for the engine and the variator, a malfunction of one of the sensors of the fuel injection system (GDI) or injectors, immobilizer malfunction, throttle control system malfunction, incorrect fuel pressure, abnormal combustion process, excessive intake air, etc.

Note: The indicator will be on if the throttle control system is disabled.

Erasing diagnostic trouble codes without a tester

Note: after repair, clear the fault codes from the memory of the electronic control unit.

1. Turn off the ignition (key in position "OFF").

2. After disconnecting the wire from the negative battery terminal for 10 seconds or more, reconnect the wire to the terminal.

3. Start the engine and let it idle for 10 minutes or more.

Checking with functions "SERVICE DATA" And "ACTUATOR TEST" tester

1. Check using the functions "SERVICE DATA" And "ACTUATOR TEST" tester. In the event of a malfunction, check the vehicle's electrical wiring, relevant components and parts.

2. After the repair, recheck with a tester and make sure that the incorrect input and output signal has returned to normal as a result of the repair (correspond to the norm).

3. Delete diagnostic codes of malfunction from memory of the electronic control unit of the engine.

4. Start the engine and carry out a road test to ensure that the problem is corrected.

Data of the current state of the engine ("freeze")

In case of detection of several faults, the memory of the control unit will store "freeze" data only for the fault that was detected first. Table "freeze frame" This data lists the components, information about the state of which will be recorded in the memory of the electronic engine control unit in the event of a malfunction.

Table. "Freeze" data.

| № | Parameter | Unit rev. |

| 12 | Mass air flow sensor | Hz |

| 13 | Intake air temperature sensor | °C |

| 21 | Engine coolant temperature sensor | °C |

| 22 | crankshaft position sensor | rpm |

| 24 | Vehicle speed sensor | km/h |

| 44 | Ignition advance angle | °to TDC |

| 81 | Long term fuel balance | % |

| 82 | short term fuel balance | % |

| 87 | Calculated load | % |

| 8A | Throttle position sensor (channel #1) | % |

| A1 | Oxygen sensor | mV |

Checks on the connector of the electronic engine control unit and variator

Note:

- If any deviation from the nominal value is found, then check the corresponding sensor, actuator and corresponding wires.

- After repairing or replacing an assembly, recheck to ensure that the problem has been corrected.

Checking the voltage at the terminals of the connector on the side of the electronic control unit

1. Disconnect the engine and CVT ECM connector and connect the test harness between the connectors, or use a voltmeter needle tester to check at the harness side connector.

Attention: probe short circuit "pluses", connected to the output of the connector, on "mass" may cause damage to the wiring, sensor, electronic control unit, or all of the above items.

2. With the connector of the electronic control unit connected, measure the voltage between the terminals "masses" control unit and each corresponding terminal of the unit connector.

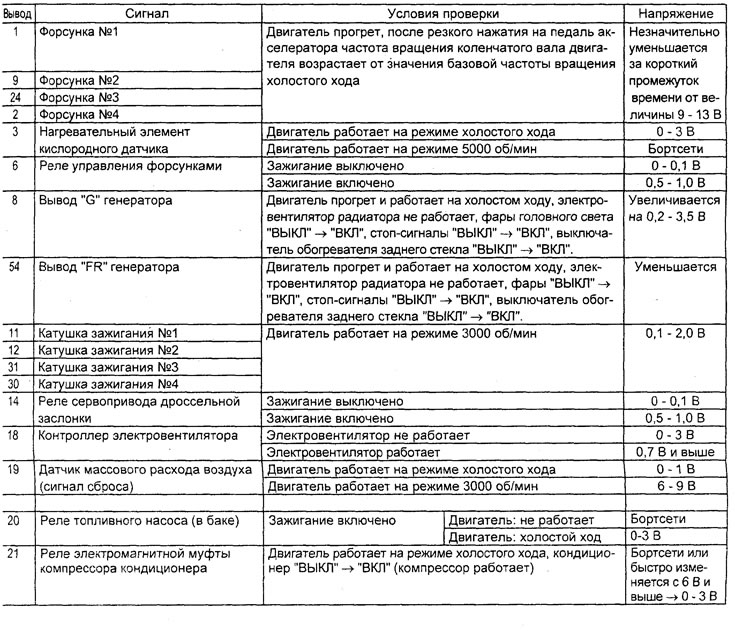

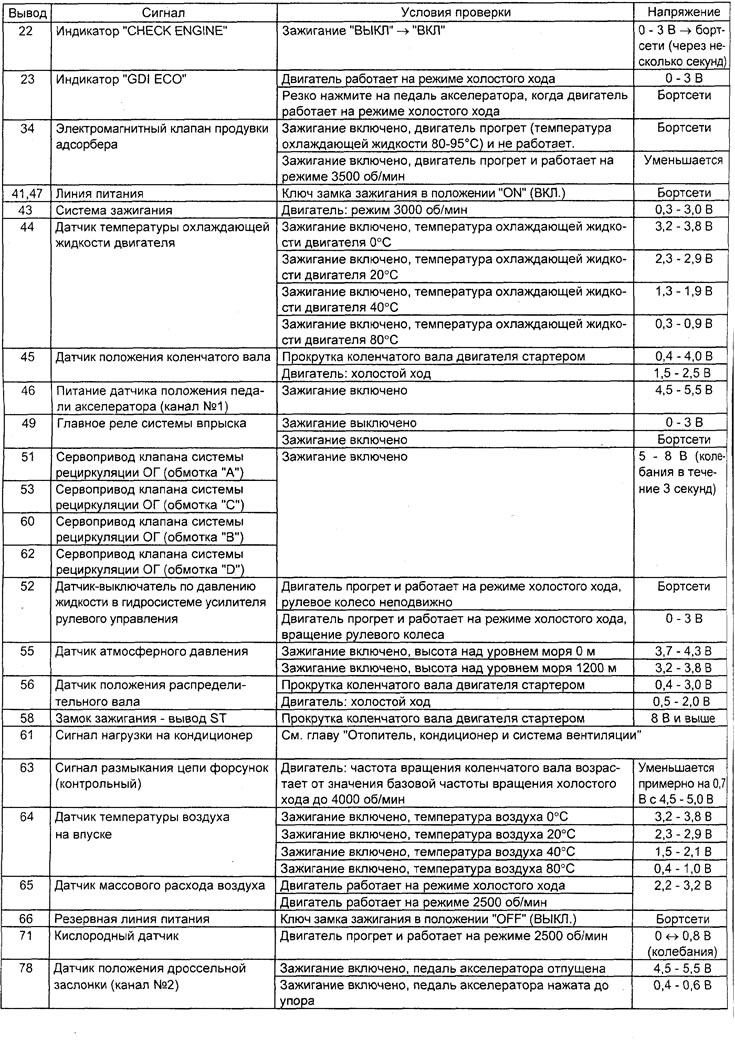

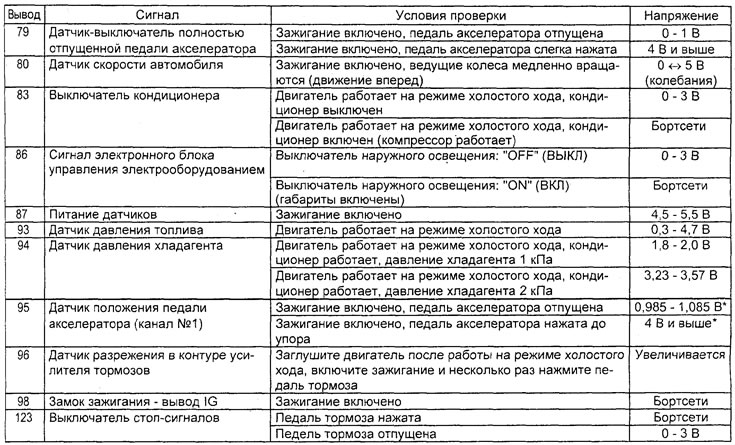

3. Checked conclusions and values are indicated in the table "Checking the voltage at the terminals of the connector of the electronic control unit for the engine and the variator".

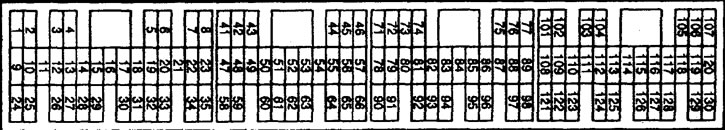

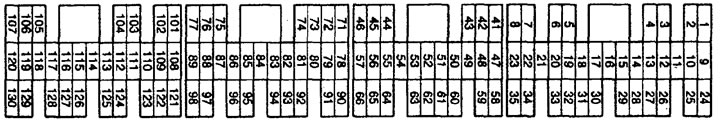

4. The location of the pins is shown in the corresponding figures.

Checking the state of resistance at the terminals of the connector of the electronic unit from the side of the wiring harness

1. Before starting the test, turn the ignition key to position "OFF" (OFF) and disconnect the ECU connector.

2. Connect the test lead harness to the connector on the harness side, then check the resistance and continuity between the connector pins.

Attention:

- Do not use ohmmeter needle probes.

- If the terminals to be tested are reversed or the terminals are incorrectly connected to "weight", the result may be damage to the wiring, sensors, electronic control unit and / or ohmmeter.

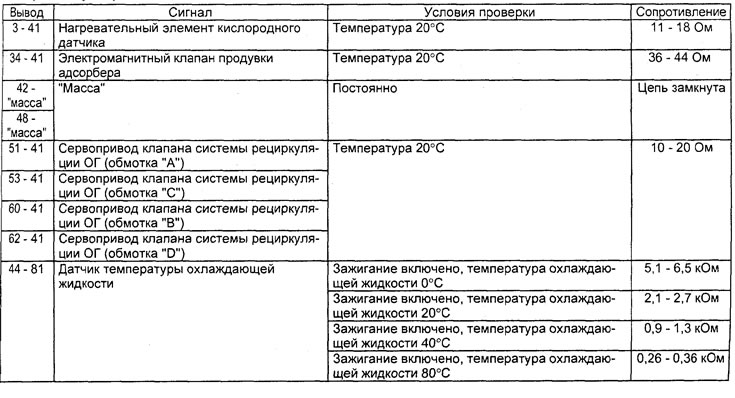

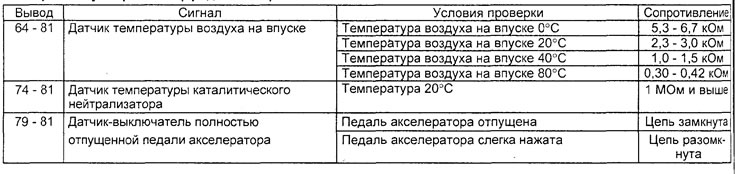

3. Checked conclusions and values are indicated in the table "Check of resistance on conclusions of a socket of the electronic control unit from a plait of wires".

4. The pinout is shown in the corresponding figure.

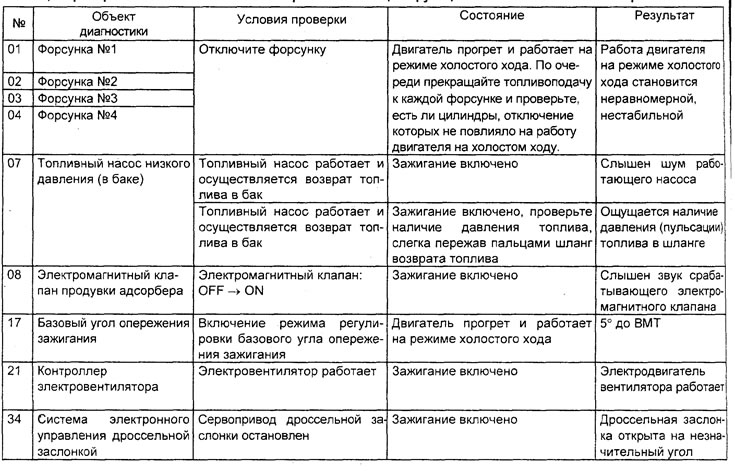

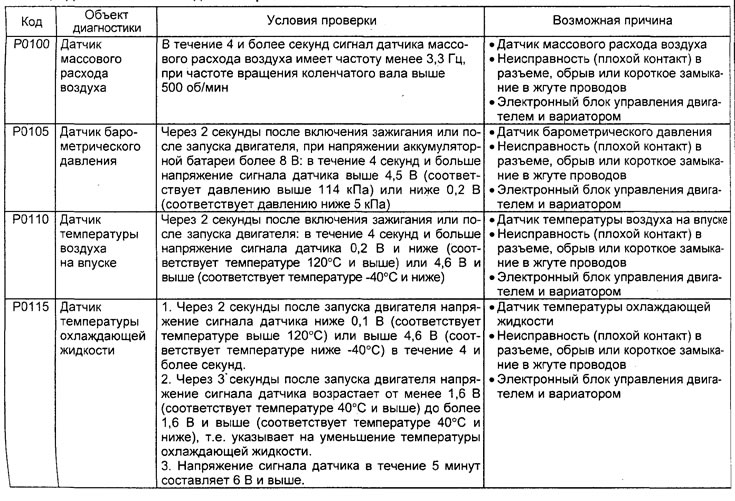

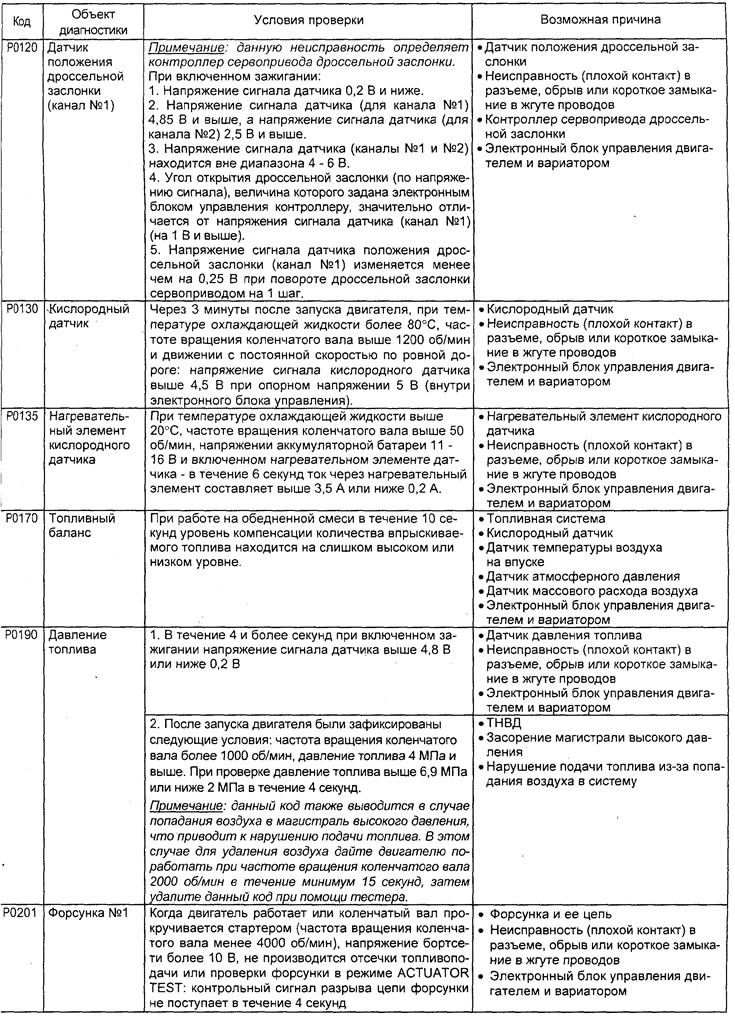

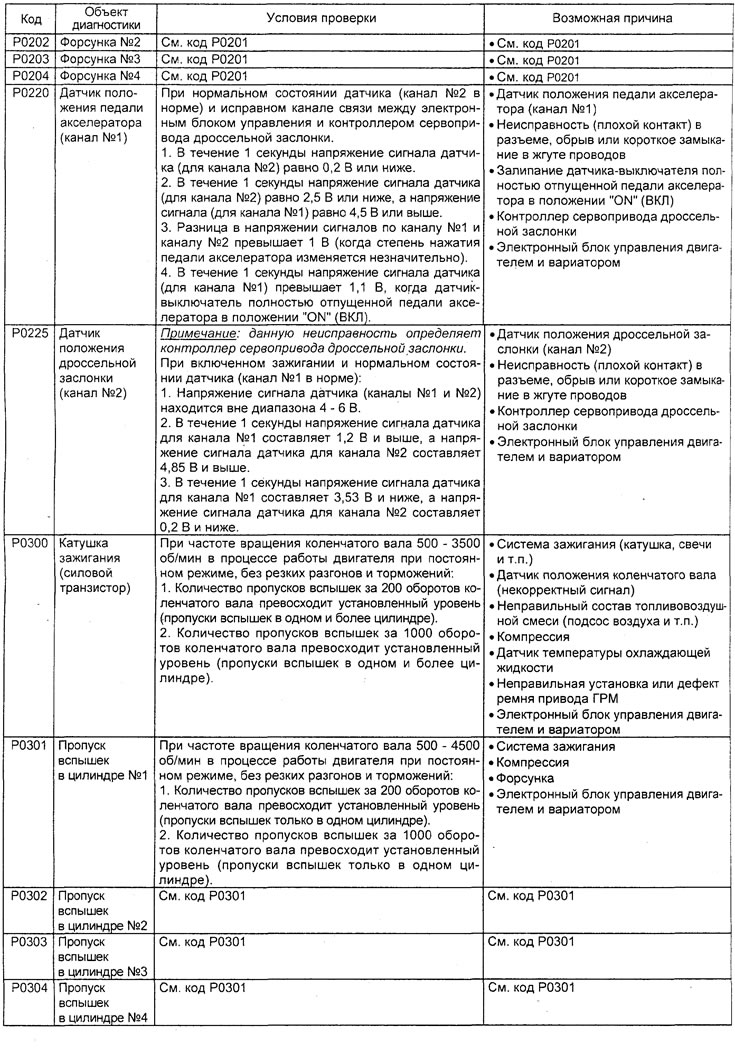

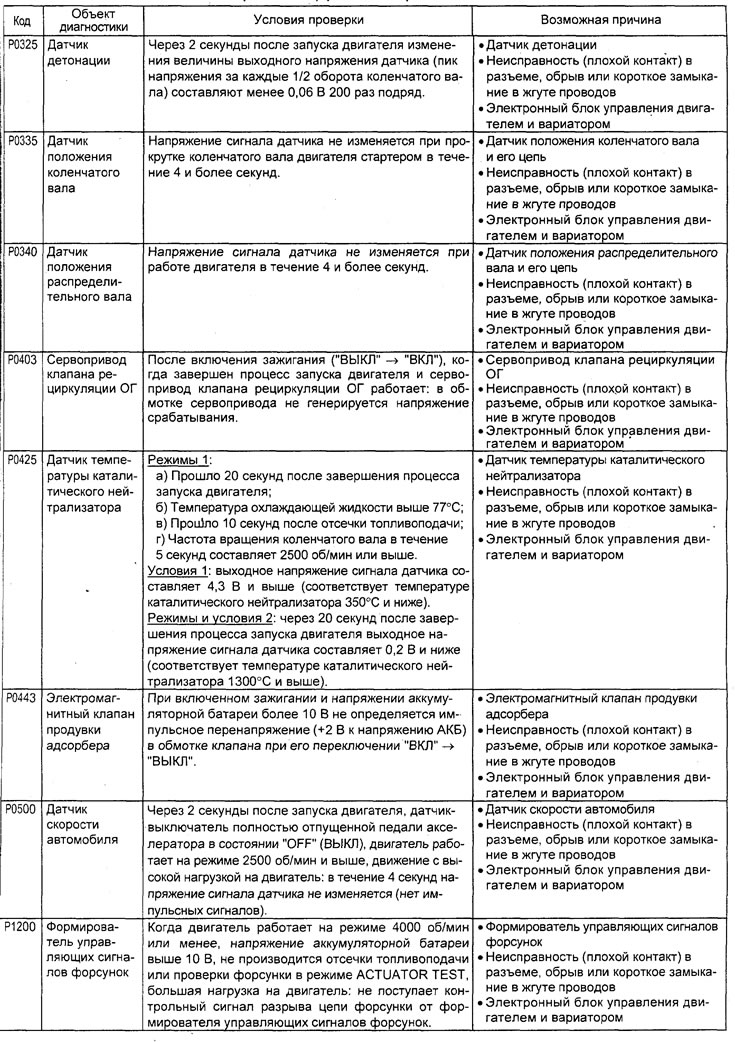

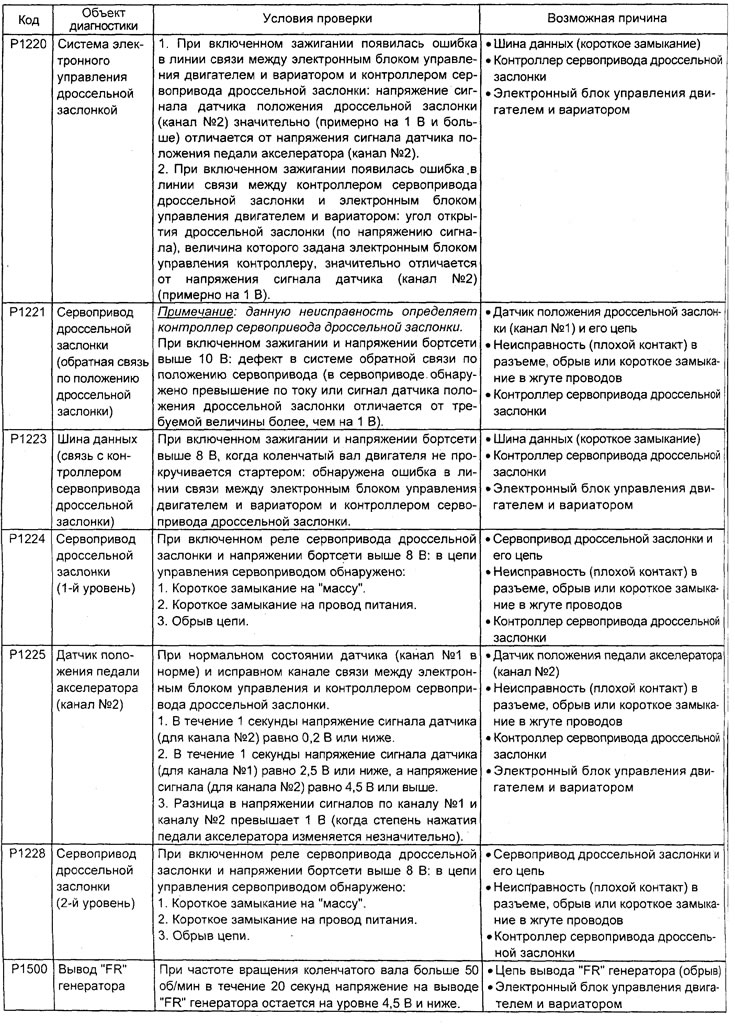

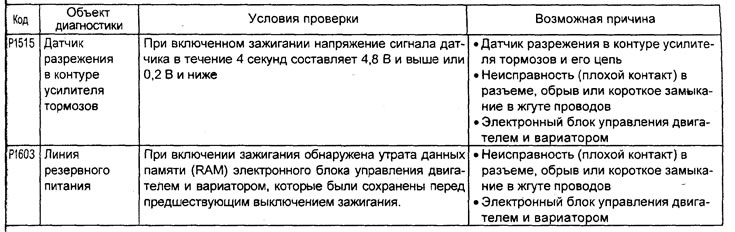

Table. Diagnostic Trouble Codes.

Connector on the side of the electronic control unit for the engine and variator.

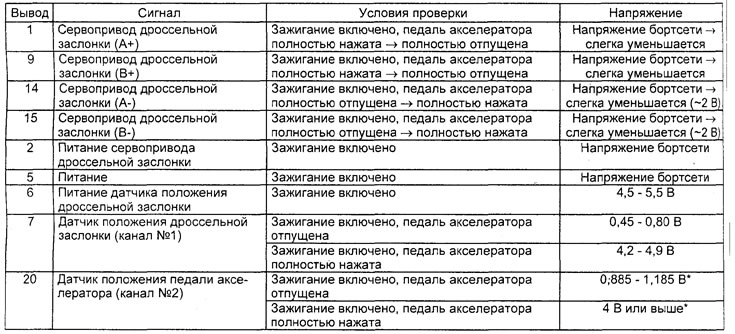

Table. Checking the voltage at the terminals of the electronic control unit for the engine and the variator.

Note: symbol "*" the table indicates that for the accelerator pedal position sensor (channel #1) it is necessary to check the difference between the values at different positions of the accelerator pedal.

The connector of the electronic control unit for the engine and the variator on the side of the wiring harness.

Table. Checking the resistance at the terminals of the connector of the electronic control unit for the engine and the variator from the side of the wiring harness.

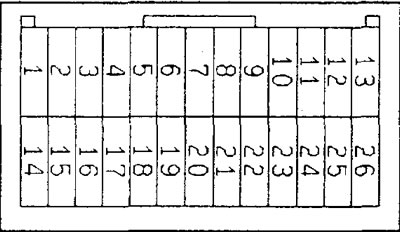

Connector on the side of the throttle servo controller.

Table. Checking the voltage at the terminals of the throttle servo controller.

Note: symbol "*"the table indicates that for the accelerator pedal position sensor (channel #2) it is necessary to check the difference between the values at different positions of the accelerator pedal (must be at least 4 V).

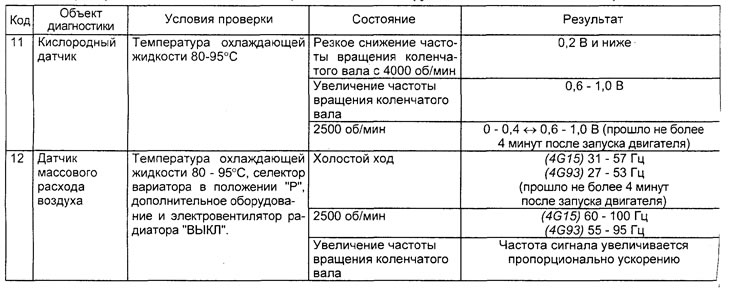

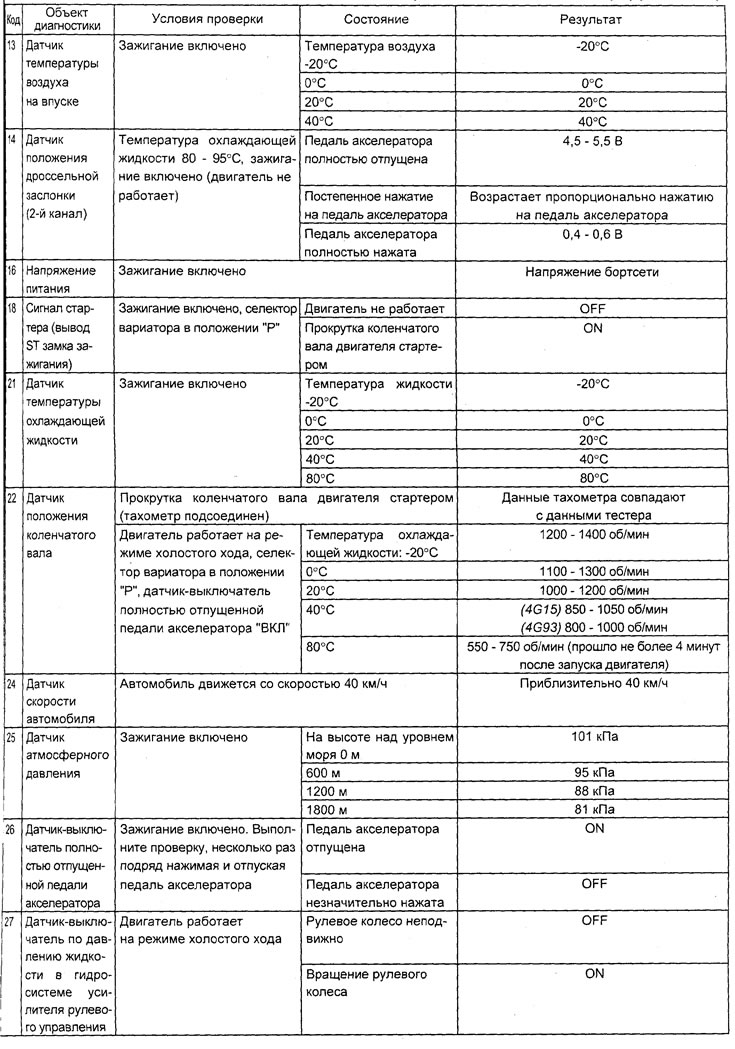

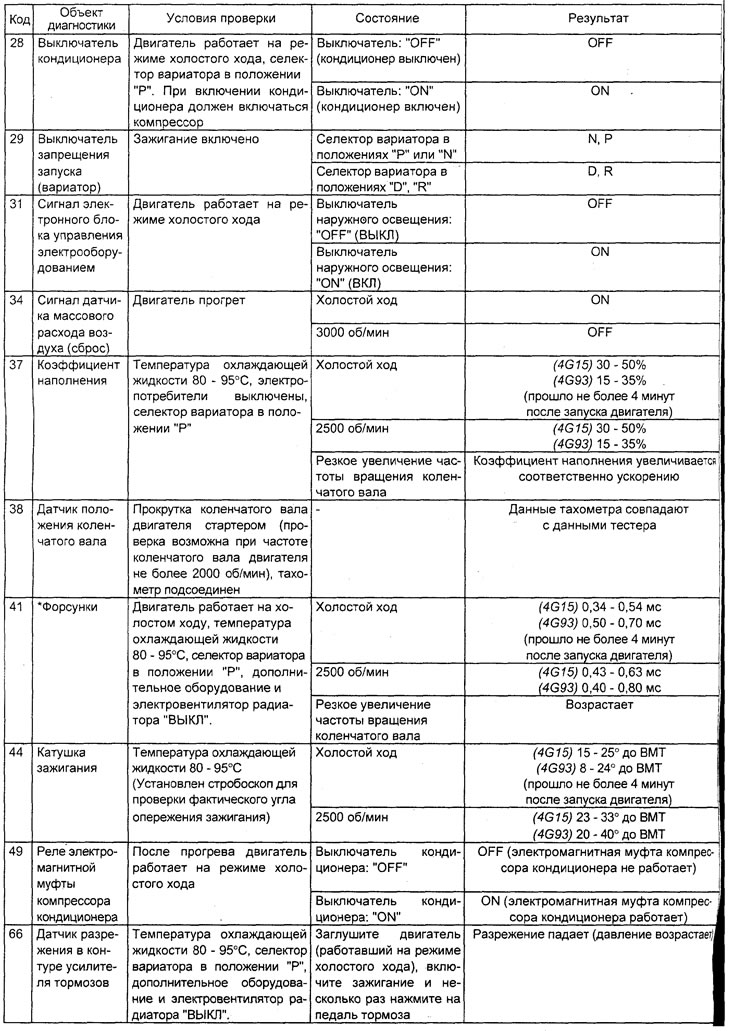

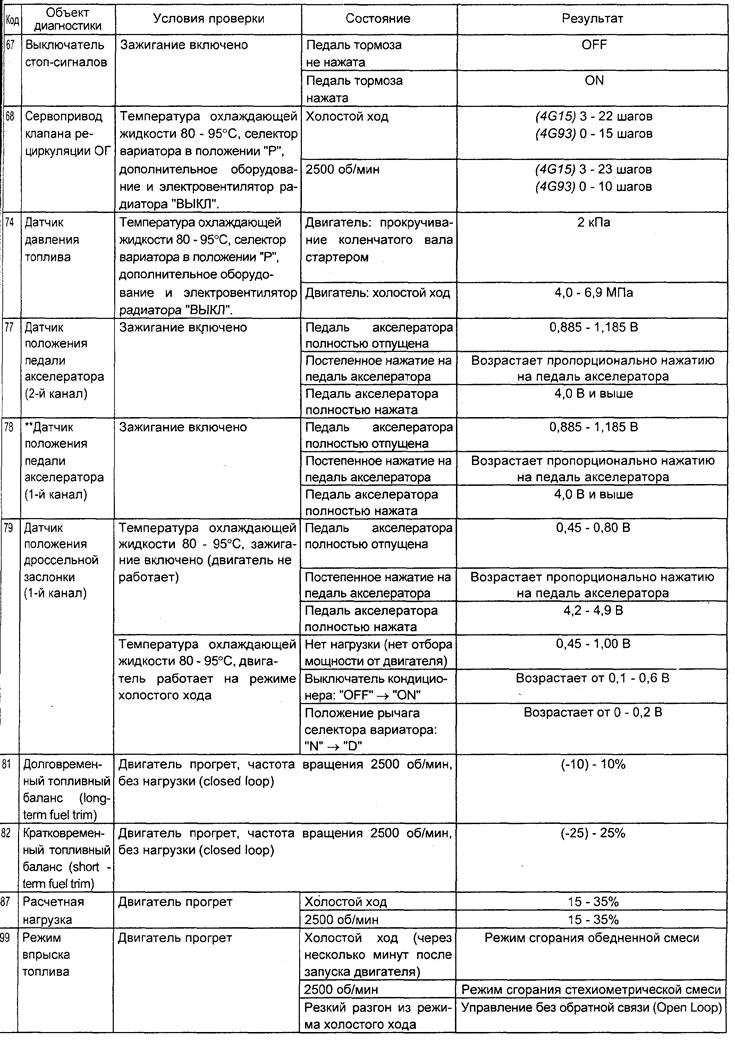

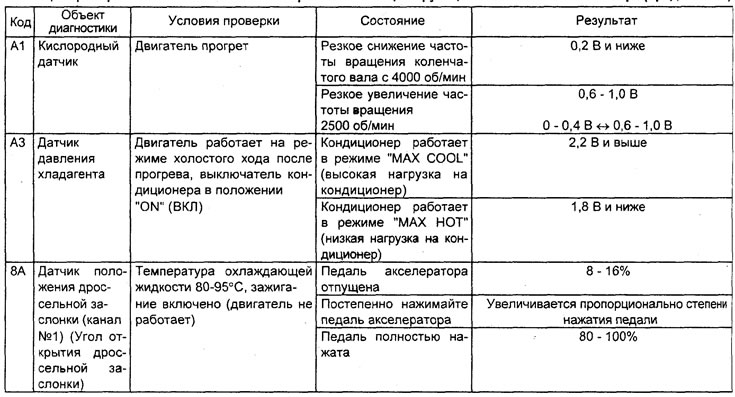

Table. Checking the components of the injection system using the function "SERVICE DATA" tester.

Note:

- When translating the variator selector to position D, it is necessary to keep the brake pedal fully depressed to prevent the vehicle from moving forward;

- -"*"-On a new car (with a mileage of 500 km or less) the result can sometimes differ up to 10% from the nominal value.

- -"*"- When the signal voltage of the accelerator pedal position sensor (channel #1) equal to 1.185-1.685 V, the sensor-switch of the fully released accelerator pedal should move from the position "ON" into position "OFF". If the voltage of the sensor signal changes already after the accelerator pedal is fully released, then the sensor-switch of the fully released accelerator pedal and the accelerator pedal position sensor (channel #1) needs to be adjusted.

Table. Checking the components of the injection system using the function "ACTUATOR TEST" tester.