Removing

- Before starting to remove parts, carry out the following operations:

- A) Drain the coolant

- b) (GDI engines) Remove the decorative engine cover.

- V) Remove the air filter.

- G) Remove the throttle body.

- d) (GDI engines) Remove ignition coils.

- e) (MPI motors) Remove the fuel manifold assembly with injectors.

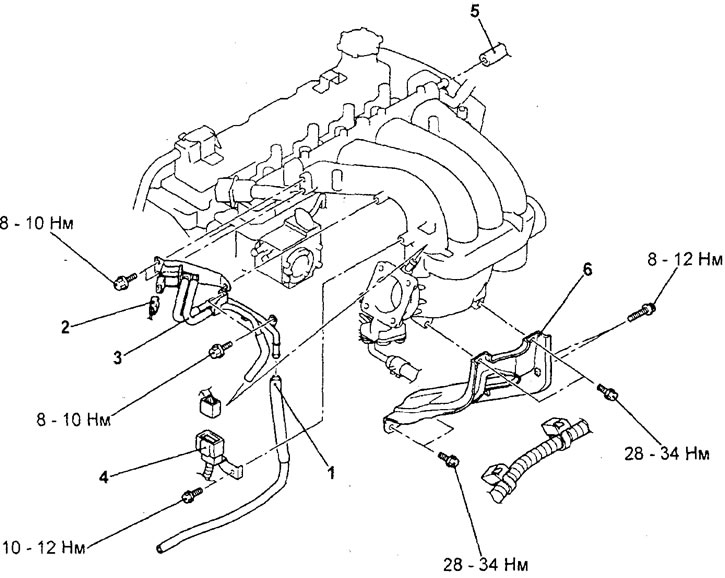

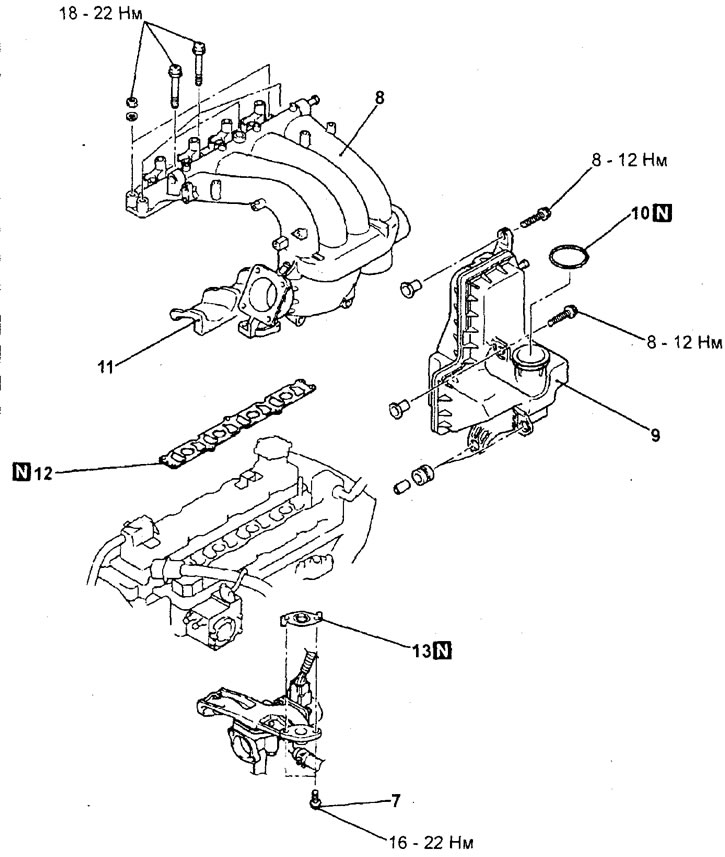

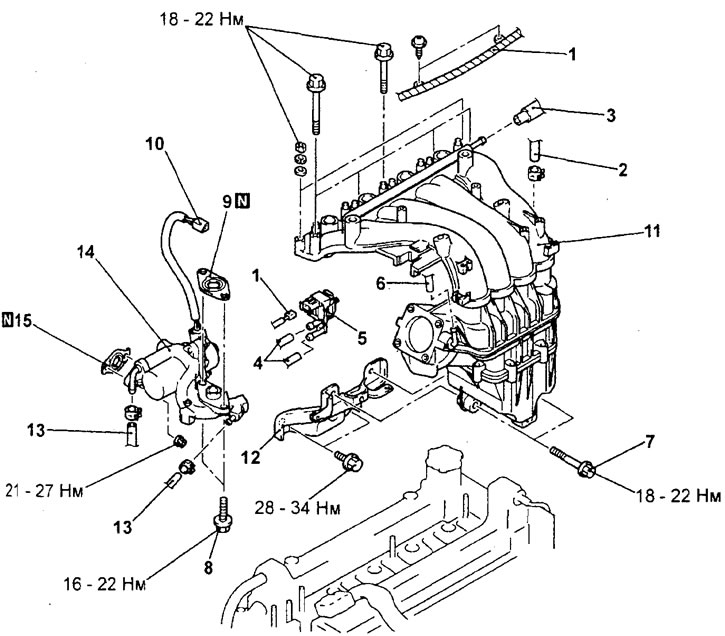

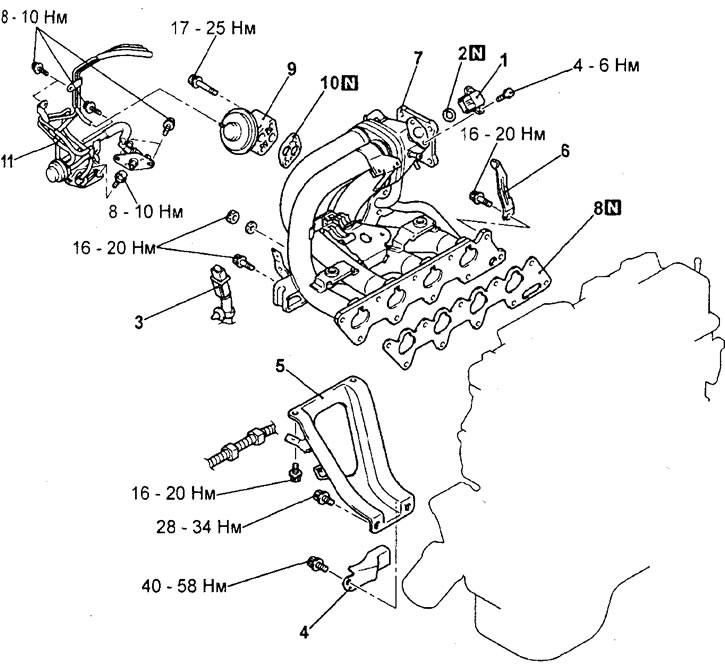

− Removal of parts is carried out in the order of numbers indicated in the figure "Removing the intake manifold".

Removing the intake manifold (engine 4G15-GDI). 1 - canister purge system vacuum hose connection, 2 - canister purge solenoid valve connector, 3 - canister purge solenoid valve bracket and vacuum tubes and hose assemblies, 4 - EGR valve servo connector, 5 - positive crankcase ventilation system hose, 6 - intake manifold mount.

Removing the intake manifold (4G15-GDI engine, continued). 7 - EGR pipe bolt, 8 - intake manifold, 9 - intake manifold resonator, 10 - O-ring, 11 - insulator, 12 - intake manifold gasket, 13 - EGR pipe gasket.

Removing the intake manifold (engine 4G93-GDI). 1 - engine management system wiring harness, 2 - brake booster vacuum hose, 3 - positive crankcase ventilation system hose, 4 - vacuum hose, 5 - canister purge solenoid valve, 6 - canister purge system hose, 7 - intake manifold and strut mounting bolt intake manifold, 8 - EGR pipe bolt to intake manifold, 9 - EGR pipe gasket, 10 - EGR valve servo connector, 11 - intake manifold assembly, 12 - intake manifold strut, 13 - cooling system hose, 14 - EGR pipe and EGR valve servo assembly, 15 - EGR pipe gasket.

Removing the intake manifold (4G15-MPI engine). 1 - intake manifold absolute pressure sensor, 2 - O-ring, 3 - knock sensor connector, 4 - powertrain bracket, 5 - intake manifold strut, 6 - engine mount bracket, 7 - intake manifold, 8 - intake manifold gasket, 9 - EGR valve, 10 - EGR valve gasket, 11 - Vacuum tubes and hose assemblies.

− (Engine 4G15-GDI) When removing parts, pay attention to the intake manifold removal operation.

Carefully detach the resonator from the intake manifold, then remove the intake manifold.

Examination

1. Check all parts for damage and cracks, if any, replace the part. Clean parts if necessary. Attention: when cleaning, do not allow foreign particles to enter the intake ducts of the cylinder head and intake manifold.

2. Check the condition of the intake manifold gasket.

3. Check for clogging of the openings of the vacuum outlet fittings, the coolant passage channels, the channels of the forced crankcase ventilation system, as well as the channels for the passage of exhaust gases and the channels of the exhaust gas recirculation system (EGR).

4. Using a straightedge and a set of feelers, measure the flatness of the mating surface of the cylinder head, as well as the mating surfaces of the intake manifold.

Non-flatness of the mating surface for the gasket:

- Nominal - 0.15 mm or less

- Maximum allowable - 0.20 mm

5. In case of detection of defects during the inspection of the above points, the part must be replaced.

Installation

− Installation of parts is carried out in the reverse order of removal.

− After completing the installation of the parts, perform the following operations:

- A) (MPI motors) Install the fuel manifold assembly with injectors.

- b) (GDI engines) Install the ignition coils.

- V) Install the throttle body.

- G) Install the air filter.

- d) (GDI engines) Install the decorative engine cover.

- e) Fill with coolant.