General information

1. When the car is moving, the fuel vapors accumulated in the canister are sent through the canister purge vacuum or solenoid valve, vacuum hose and throttle body fitting to the intake manifold and then burn out in the engine.

2. Electronic control unit (based on signals from the mass air flow sensor, coolant temperature sensor, barometric pressure sensor and intake air temperature sensor) opens and closes the canister purge solenoid valve, regulating the flow of fuel vapor into the intake manifold. When the coolant temperature is low or the air flow is low (e.g. at idle) the electronic engine control unit turns off the solenoid valve, and the valve blocks the flow of fuel vapor into the intake manifold. This ensures the stability of the engine when it is cold or running under light load, but also reduces emissions of toxic substances.

Note: Sensor test procedures are given in chapter "fuel injection system".

Checking the adsorber purge system

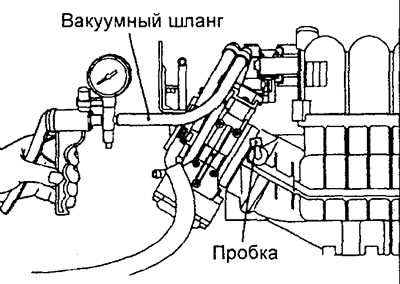

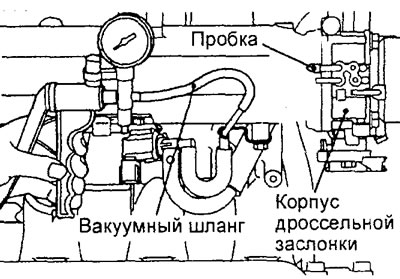

1. Disconnect the vacuum hose (for MPI engines with red stripe) from intake manifold (GDI engines) or throttle body (MPI motors) and connect a hose to a large vacuum pump.

2. Close with a stopper the union of the channel of a purge of an adsorber from which the vacuum hose has been disconnected.

Engine 4G15-GDI.

Engine 4G93-GDI.

Engine 4G15-MPI.

Engine 4G93-MPI.

3. Run a system check (engine condition and vacuum), when the engine is not warm (coolant temperature 40°C or less). Using a vacuum pump, create a vacuum of 53 kPa (400 mmHg), when the engine is idling.

A) When the engine is idling, the vacuum must be maintained.

b) When the engine is running at 3000 rpm, the vacuum must be maintained.

4. Run a system check (engine condition and vacuum), when the engine is warm (coolant temperature 80°C or more). Using a vacuum pump, create a vacuum of 53 kPa (400 mmHg), when the engine is idling.

A) When the engine is idling, the vacuum must be maintained.

b) 3 minutes after starting the engine, when the engine is running at 3000 rpm, the vacuum will decrease.

Checking the canister purge vacuum hose fitting

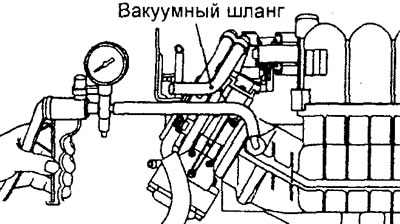

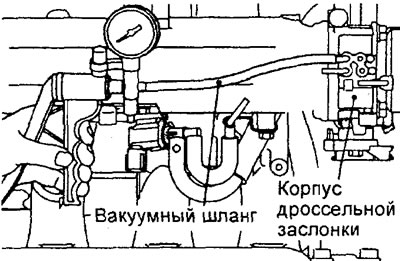

1. Disconnect the vacuum hose from the canister purge channel fitting on the intake manifold (GDI engines) or throttle body (MPI motors).

Note:

- - For GDI engines, the vacuum hose is black.

- - For MPI engines, a vacuum hose with a red stripe.

2. Connect a hand vacuum pump to the fitting.

Engine 4G15-GDI.

Engine 4G93-GDI.

Engine 4G15-MPI.

Engine 4G93-MPI.

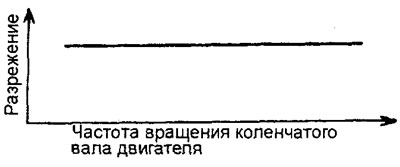

3. Start the engine and check that as the engine speed increases, the vacuum remains almost constant.

Note: If there is no vacuum, then there is probably a deposit in the vacuum hose fitting port on the intake manifold and needs to be cleaned.

Checking the canister purge solenoid valve

Note: When disconnecting a vacuum hose, always mark it first so that the hose is in its original position when connected.

1. Disconnect the vacuum hose (for MPI engines with red stripe) from the solenoid valve.

2. Disconnect the harness connector from the solenoid valve.

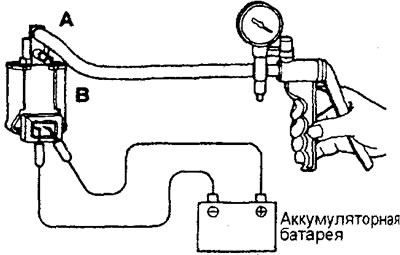

3. Connect a hand vacuum pump to the "A" solenoid valve from which the vacuum hose was disconnected.

4. Create a vacuum with a vacuum pump and check the operation of the solenoid valve.

A) Check that the vacuum in the valve is maintained when power is not connected to the valve terminals.

b) Check that the vacuum in the valve decreases when battery power is connected to the valve terminals.

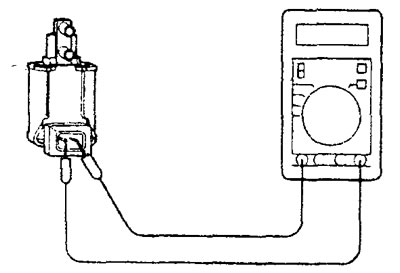

5. Measure the resistance between the solenoid valve leads.

Rated value (at 20°C) — 30-34 Ohm

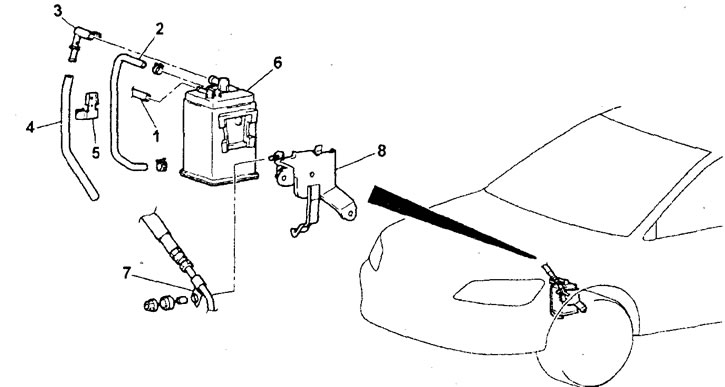

Removal and installation of an adsorber

− Remove the air filter assembly before beginning to remove parts.

- Parts are removed in the order of the numbers shown in the figure "Removing the adsorber assembly".

− Installation of parts is carried out in the reverse order of removal.

− After completing the installation of the parts, install the air filter assembly.

Removing the adsorber assembly. 1 - hose connection of the fuel vapor recovery system, 2 - canister purge hose, 3 - ventilation tube, 4 - canister purge hose, 5 - hose clamp, 6 - adsorber, 7 - high pressure fuel hose clamp, 8 - adsorber mounting bracket.