Removing

Perform the following operations before beginning to remove parts.

A) Release residual pressure from the high pressure fuel line (see chapter "fuel injection system (MPI)").

b) Remove the engine crankcase guard.

V) Drain coolant and engine oil.

G) (Engine 4G93) Remove the radiator.

d) Remove the hood.

e) Remove the air filter.

and) Remove the battery and battery tray.

h) (Engine 4G15) Disconnect the accelerator pedal cable

And) Disconnect the exhaust pipe from the exhaust manifold.

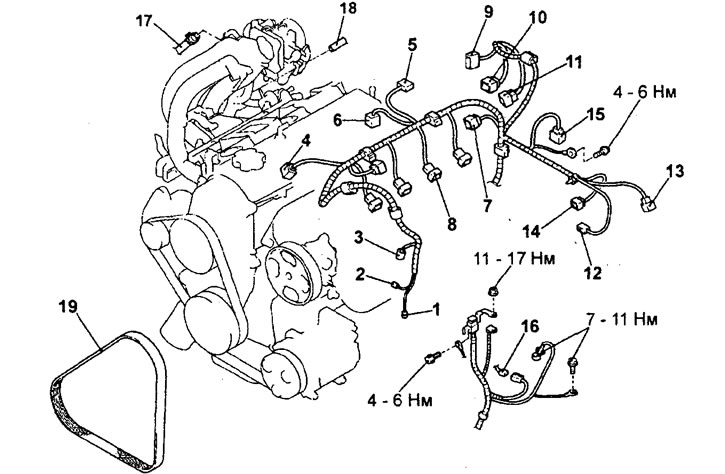

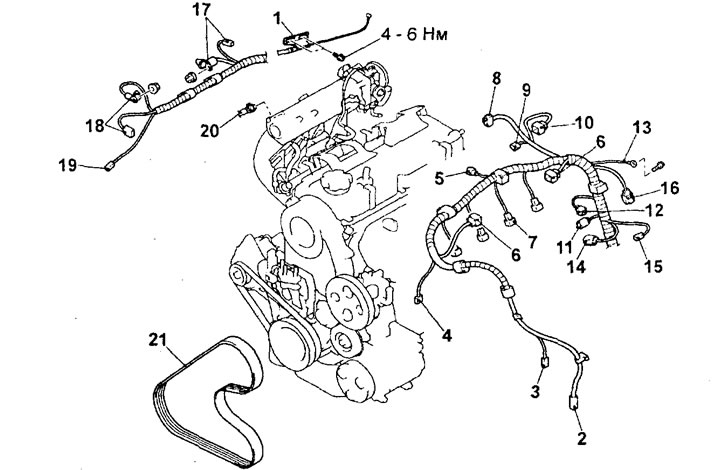

Removing the engine assembly (4G15 engine). 1 - connector for the electromagnetic clutch of the air conditioning compressor, 2 - connector for the sensor-switch for fluid pressure in the hydraulic system of the power steering, 3 - connector for the crankshaft position sensor, 4 - connector for the knock sensor, 5 - absolute pressure sensor in the intake manifold (with integrated intake manifold air temperature sensor), 6 - EGR solenoid valve connector, 7 - ignition coil connector, 8 - injector connector, 9 - throttle position sensor connector, 10 - idle speed control servo connector, 11 - canister purge solenoid valve connector, 12 - sensor connector coolant temperature sensor, 13 - oxygen sensor connector, 14 - coolant temperature sensor connector, 15 - camshaft position sensor connector, 16 - battery and engine management harness connector, 17 - brake booster vacuum hose connection, 18 - connection vacuum hose of the fuel vapor recovery system, 19 - drive belt of the power steering pump and air conditioning compressor.

Removing the engine assembly (4G15 engine, continued). 20 - power steering pump, 21 - air conditioning compressor, 22 - upper radiator hose connection, 23 - lower radiator hose connection, 24 - heater hose connection, 25 - fuel return hose connection, 26 - high pressure fuel hose flange connection, 27 - O-ring (remove the gearbox), 28 - engine support assembly, 29 - engine assembly.

Note: the connections marked with the symbol should first be tightened only in advance, and the final tightening with the specified torque should be made after the engine is completely lowered onto the supports.

3. Removing the power steering pump.

Remove the power steering pump from the engine along with the hoses connected to it.

Note: After removal, secure the power steering pump with hoses with wire in a place where it will not be obstructed or damaged when removing and installing the engine assembly.

4. Removing the air conditioning compressor.

Disconnect the A/C compressor wire connector and remove the compressor from its bracket along with the connected hoses.

Note: after removal, use a wire to hang the air conditioning compressor assembly with hoses on the body in a place where they will not interfere with the removal and installation of the engine assembly.

5. Removing the upper and lower radiator hoses.

Before disconnecting the upper and lower radiator hoses, mark the relative position on the hose and hose clamp.

Removal of parts is carried out in the order of the numbers indicated in the figure "Removing the engine assembly".

When removing parts, pay attention to the following operations:

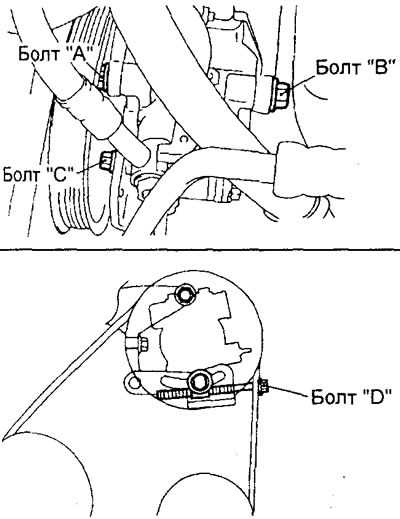

1. (Engine 4G 15) Removing the drive belt for the power steering pump and air conditioning compressor.

A) Loosen the bolts "A", "IN" And "WITH" power steering pump.

b) Loosen the adjusting bolt "D" to relieve belt tension, then remove the belt.

Attention: in case of reuse of the drive belt of the power steering pump and air conditioning compressor, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

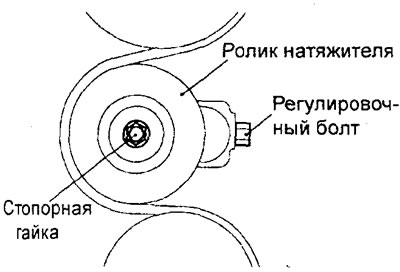

2. (Engine 4G93) Removing the drive belt for the power steering pump and air conditioning compressor.

A) Loosen the lock nut of the belt tensioner pulley for the power steering pump and air conditioning compressor.

b) Loosen the adjusting bolt to release the belt tension, then remove the belt.

Attention: in case of reuse of the drive belt of the power steering pump and air conditioning compressor, it is necessary to chalk on the back (non-working) belt surface an arrow indicating the direction of rotation (clockwise).

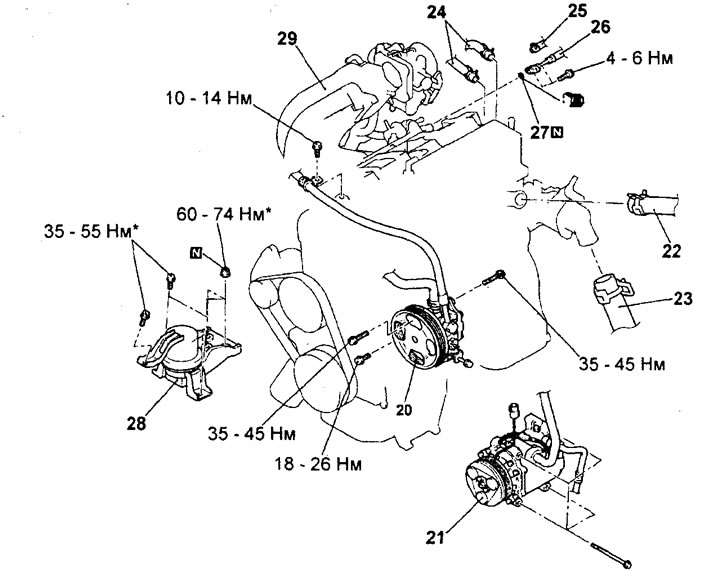

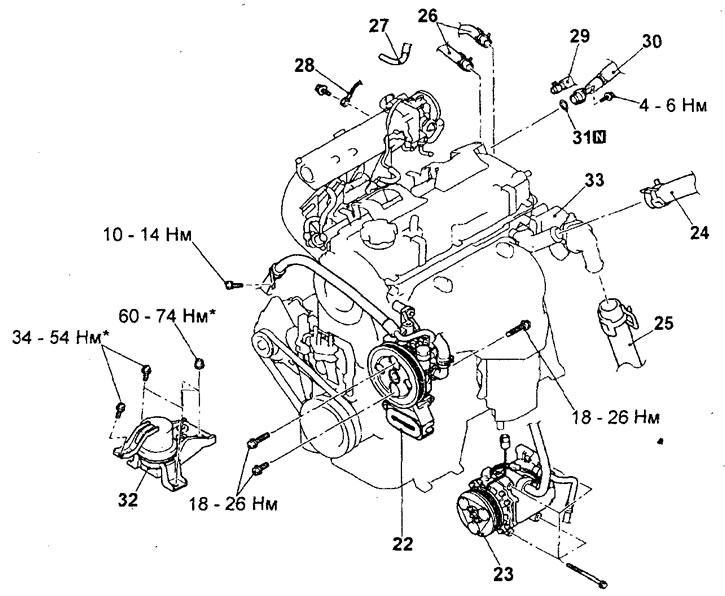

Removing the engine assembly (4G93 engine). 1 - accelerator pedal cable connection, 2 - air conditioning compressor electromagnetic clutch connector, 3 - power steering fluid pressure switch connector, 4 - crankshaft position sensor connector, 5 - canister purge solenoid valve connector, 6 - coil connector ignition, 7 - injector connector, 8 - throttle position sensor connector, 9 - idle speed control servo connector, 10 - EGR valve servo connector, 11 - coolant temperature sensor connector, 12 - camshaft position sensor connector, 13 - wire connection "masses", 14 - knock sensor connector, 15 - coolant temperature gauge sensor connector, 16 - oxygen sensor connector, 17 - starter connector, 18 - alternator connectors, 19 - engine oil emergency pressure sensor connector, 20 - brake booster vacuum hose connection, 21 - a drive belt for the power steering pump and the air conditioning compressor.

Removing the engine assembly (4G93 engine, continued).22 - power steering pump, 23 - air conditioning compressor, 24 - upper radiator hose connection, 25 - lower radiator hose connection, 26 - heater hose connection, 27 - positive crankcase ventilation hose connection, 28 - wire connection "masses", 29 - fuel return hose connection, 30 - high pressure fuel hose flange connection, 31 - O-ring (remove the gearbox), 32 - engine support assembly, 33 - engine assembly.

Note: the connections marked with the symbol should first be tightened only in advance, and the final tightening with the specified torque should be made after the engine is completely lowered onto the supports.

3. Removing the power steering pump.

Remove the power steering pump from the engine along with the hoses connected to it.

Note: After removal, secure the power steering pump with hoses with wire in a place where it will not be obstructed or damaged when removing and installing the engine assembly.

4. Removing the air conditioning compressor.

Disconnect the A/C compressor wire connector and remove the compressor from its bracket along with the connected hoses.

Note: after removal, use a wire to hang the air conditioning compressor assembly with hoses on the body in a place where they will not interfere with the removal and installation of the engine assembly.

5. Removing the upper and lower radiator hoses.

Before disconnecting the upper and lower radiator hoses, mark the relative position on the hose and hose clamp.

6. Removing the engine mount.

A) Place a rolling hydraulic jack under the engine.

b) Remove the special tools used to remove the gearbox.

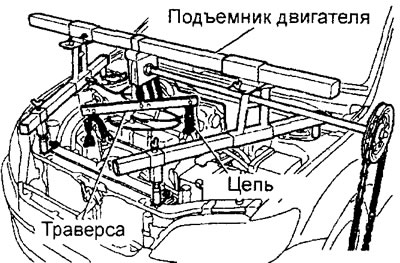

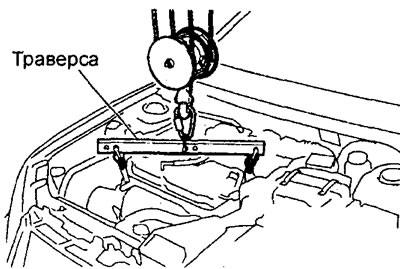

V) Fasten the motor to the yoke and hang it from a hoist or similar device (special device).

Engine 4G15.

Engine 4G93.

G) Insert a piece of wood between the jack foot and the engine oil pan, raise the engine slightly to relieve the weight of the engine support.

d) Loosen the nuts and bolts of the bracket and remove the engine support assembly with the bracket.

7. Removing the engine assembly.

A) Check that all cables, wires are disconnected from the engine (electrical connectors), hoses and other connections.

b) Install special tools on the engine (engine hoist and traverse or any other similar tool).

V) Using the special tools, slowly lift the engine assembly up from the engine compartment so that it does not move to the side.

Installation

Installation is made in an order, the return to removal.

When installing parts, pay attention to the following operations:

1. Installing the engine assembly.

A) With the help of special devices (engine lift and traverse) slowly lower and install the engine assembly into the engine compartment so that it does not move to the side.

b) Remove the special tools from the engine (engine lift and traverse).

V) When installing the engine, carefully check that the wires, tubes, hoses and wire connectors are connected correctly, that they are not pinched, twisted, damaged, etc.

2. Installing the engine mount.

A) Place a hydraulic jack under the engine (by inserting a block of wood between the jack foot and the engine oil pan) and install the engine support by adjusting the position of the engine with a jack.

b) Support the engine with a jack.

V) Supporting the engine with a special tool (jack), disconnect the hoist.

3. Installing the O-ring and high pressure fuel hose flange.

A) Apply a small amount of engine oil to the sealing lip of the O-ring around its entire circumference.

b) Rotate the flange of the high pressure fuel hose to the right and left, carefully install the hose without damaging the O-ring. After connecting, check that the hose rotates smoothly.

V) If the hose flange does not rotate smoothly, the O-ring may be pinched. Disconnect the high pressure fuel hose flange and check the o-ring for damage, then repeat the installation step "b".

G) Tighten the high pressure fuel hose flange bolts to specification.

Tightening torque - 5±1 N.m

4. Installing the lower and upper radiator hoses.

A) When connecting the radiator hose, put the hose on the branch pipe until it stops against the protrusion of the branch pipe, then tighten the clamp.

b) The hose clamp should always be installed in the position in which the clamp was previously installed. Therefore, before installing the clamp, align the alignment marks on the hose clamp and radiator hose, then connect the hose.

After completing the installation of the parts, perform the following operations:

- A) Connect the downpipe of the exhaust system from the exhaust manifold.

- b) (Engine 4G15) Connect the accelerator pedal cable

- V) Install the battery tray and battery.

- G) Install the air filter.

- d) Install the hood.

- e) (Engine 4G93) Install the radiator.

- and) Fill with coolant and engine oil.

- h) Install the engine crankcase guard.

- And) Adjust the accelerator pedal cable.

- To) Check for fuel leaks.